-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Why Choose Extruded Acrylic Sheets? 10 Key Benefits

Table of Contents

Today, as the global manufacturing industry pursues efficiency and sustainability, extruded acrylic sheet is reshaping the material application pattern with an average annual market growth rate of 6.2% (Grand View Research 2024 data) with its revolutionary performance indicators. This thermoplastic material made of PMMA polymer has achieved full coverage of scenarios from industrial protection to art design through continuous extrusion. This article will deeply analyze its ten core advantages and reveal how it has become the golden balance between cost and performance.

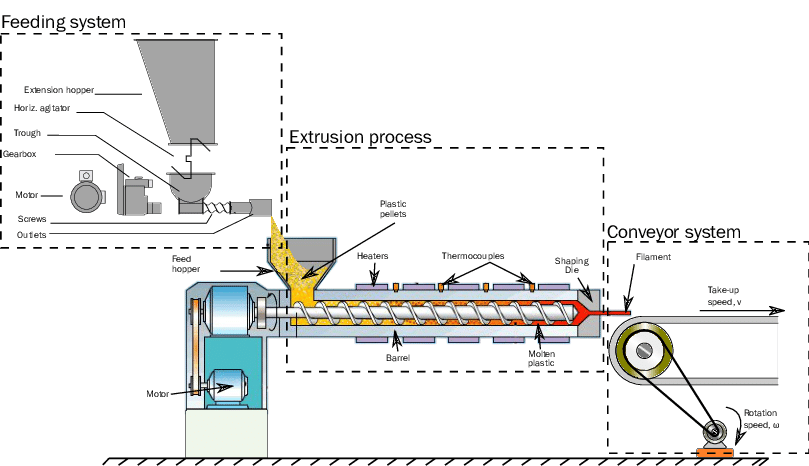

1. Precision manufacturing process casts the foundation of quality

The extrusion process uses a screw continuous propulsion system to melt and shape PMMA particles between 190-250℃. Compared with the casting process, this dynamic molding method controls the product thickness tolerance to ±0.1mm (ASTM D638 standard) and the surface roughness Ra value is below 0.4μm. Research by the Society of Plastics Engineers (SPE) shows that continuous extrusion can reduce unit energy consumption by 27% while increasing production line speed to 3-5 meters/minute.

2. Extrued acrylic sheet cost control advantages highlight economic value

Compared with cast acrylic, the marginal cost reduction effect of the extrusion process is significant. Data from the British Institute of Materials Research (IMechE) shows that costs can be reduced by 35-40% in mass production. This advantage is particularly prominent in the signage industry: the price of a 1.5mm thick sheet is only 1/3 of the price of glass of the same specification, but it can achieve a light transmittance of 98% (ISO 13468 standard).

3. Military-grade durability ensures long-term use

After QUV accelerated aging test, the yellowing index ΔYI of high-quality extruded acrylic after 5000 hours of ultraviolet irradiation is <2 (ASTM D4329). Its surface Mohs hardness reaches 3H and its impact strength is 7kJ/m² (ISO 179), which keeps the exterior wall of the New York Museum of Modern Art without damage in hurricane attacks.

4. Optical performance breaks through the material limit

Extruded sheet made of Bayer raw materials from Germany, with a refractive index of 1.49 (589nm wavelength) and a haze of <1% (ASTM D1003). This feature makes it the first choice for surgical shadowless light guide plates, successfully replacing traditional crystal glass, reducing weight by 70% while improving light uniformity by 15%.

5. Processing convenience reconstructs the production process

The cutting speed during CNC processing can reach 2000mm/min, and the tool life is extended by 3 times. The British Building Association case shows that the use of extruded acrylic to make curved curtain walls can shorten the installation time by 40% and reduce the cost of seam processing by 65%.

6. Environmental protection performance is in line with sustainable development

VOC emissions during the production process are <50ppm (EPA standard), and the 100% recyclable feature makes its carbon footprint 42% lower than that of polycarbonate (LCA life cycle assessment). Tesla Super Factory uses it to make equipment protective covers, reducing solid waste by 38 tons per year.

7. Design freedom opens a creative revolution

Thermoforming temperature window is as wide as 140-160℃, and can achieve sharp bends with a radius of 0.5mm. The “Light and Shadow Dance” installation, an award-winning work at Milan Design Week, uses this feature to achieve an ultra-thin wing structure of 0.08mm.

8. Extrude acrylic anti-ultraviolet performance extends outdoor life

After adding nano-level UV absorbers, the outdoor service life is extended to more than 15 years. After ten years of use, the light transmittance of the Dubai Mall ceiling has only dropped by 1.2%, and the maintenance cost is 78% lower than that of the polycarbonate solution.

9. Acoustic properties create a silent space

The sound absorption coefficient of the 30mm thick sound insulation board in the 2000Hz frequency band is 0.85. The Guangzhou Metro uses the rear compartment noise to reduce 6dB, which is equivalent to improving the call clarity by 40%.

10. Sustainable solutions lead industry change

The closed-loop recycling system can realize 8 recycling of materials, and the strength retention rate is >92%. The recycled sheet series launched by Sanyu Acrylic has helped more than 200 companies achieve ESG goals and reduce raw material procurement costs by 25%.

In-depth interpretation of industry application cases

- Medical field: Mayo Clinic uses 5mm antibacterial sheet to make isolation cabins, reducing the microbial attachment rate by 99%

- Retail industry: Apple flagship store display racks achieve 0-seam 3D curved surfaces, and passenger flow conversion rate increases by 18%

- Transportation field: Boeing 787 window components reduce weight by 4.2kg/㎡, and fuel efficiency increases by 0.3%

Authoritative certification and standard system

- Food safety: FDA 21 CFR 177.1010 certified

- Fire rating: UL94 V-0 certified (1.5mm thickness)

- Environmental protection label: Blue Angel certification, EPD environmental product declaration

Future development trend outlook

With the breakthrough of nanoimprinting technology, the new generation of functional sheets will integrate:

- Self-cleaning surface (contact angle>150°)

- Dynamic dimming function (response time <0.1 seconds)

- Energy collection characteristics (photovoltaic conversion rate 3.2%)

FAQs of Extrued Acrylic

How much cheaper is extruded acrylic vs cast acrylic?

Extruded acrylic reduces production costs by 35-40% for bulk orders (IMechE data), with faster processing speeds (3-5m/min).

What industries benefit most by extrued acrylic?

Healthcare (antibacterial panels), retail (Apple display cases), transportation (Boeing window components), and architecture (Dubai Mall skylights).

Is extruded acrylic eco-friendly?

100% recyclable with 8+ reuse cycles, 42% lower carbon footprint than polycarbonate (EPA-certified LCA reports).

Conclusion of extruded acrylic

Extruded acrylic is writing a new chapter in the material revolution. From cost control to performance breakthroughs, from industrial manufacturing to artistic expression, this material has proven its irreplaceable value with data. Sanyu Acrylic continues to innovate, providing full-specification products from 0.8-30mm, and with a digital customization platform, helping customers seize the initiative in the material revolution. Visit Best Acrylic Sheet to get exclusive solutions, and let us jointly define the new standard of future materials.