-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Why Choose Acrylic Lights? Top 10 Advantages Revealed

Table of Contents

Introduction of Acrylic Lamps

In the modern decoration market that pursues personalization and functionality, acrylic lamps are occupying the market at an alarming rate. According to Grand View Research data, the global acrylic material market size will reach US$9.7 billion in 2024, of which the lighting field accounts for more than 30%. This article will systematically analyze why acrylic lamps can become the common choice of designers and owners from the dimensions of material performance, design aesthetics, safety standards, etc.

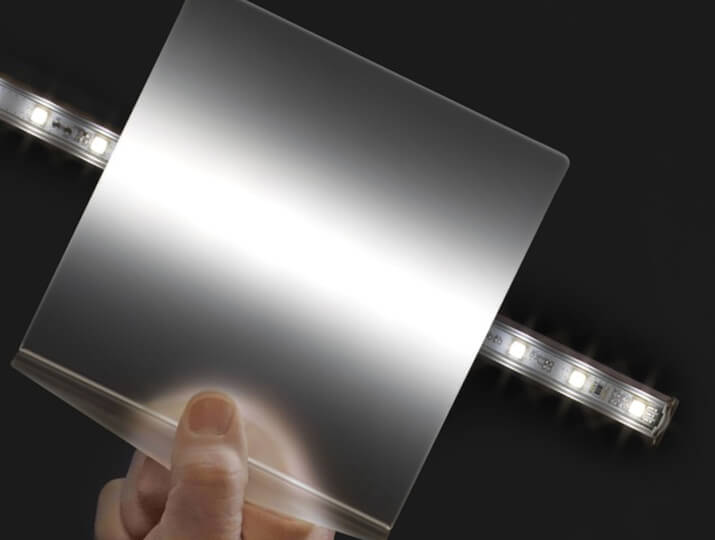

Revolutionary breakthrough in optical performance by acrylic lights

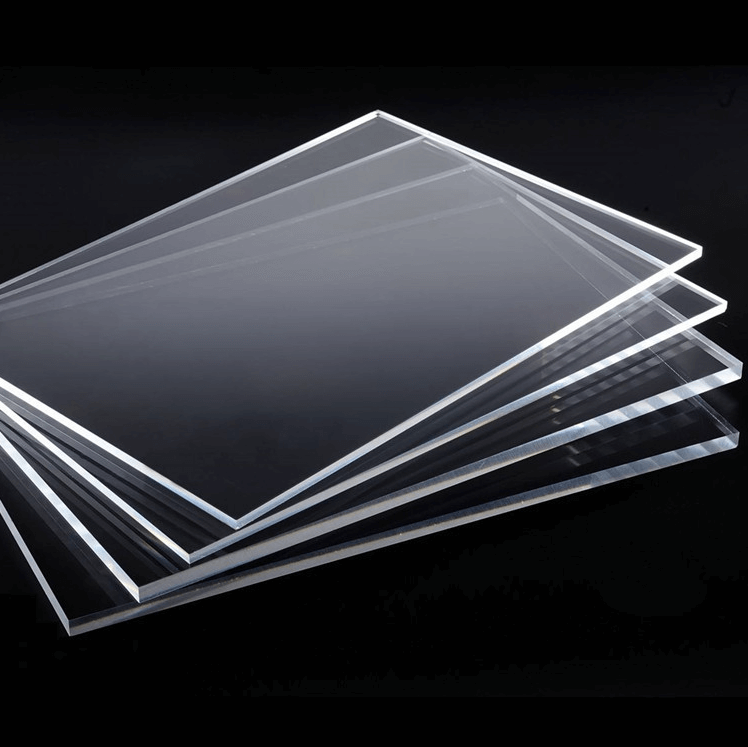

92% ultra-high light transmittance

The U.S. Department of Energy’s “Commercial Lighting Guide” points out that the light transmittance of high-quality acrylic sheets can reach 92% (data source: energy.gov), far exceeding the 85% of ordinary glass. Its built-in light diffusion layer achieves uniform light distribution and eliminates glare through nano-scale microstructure design.

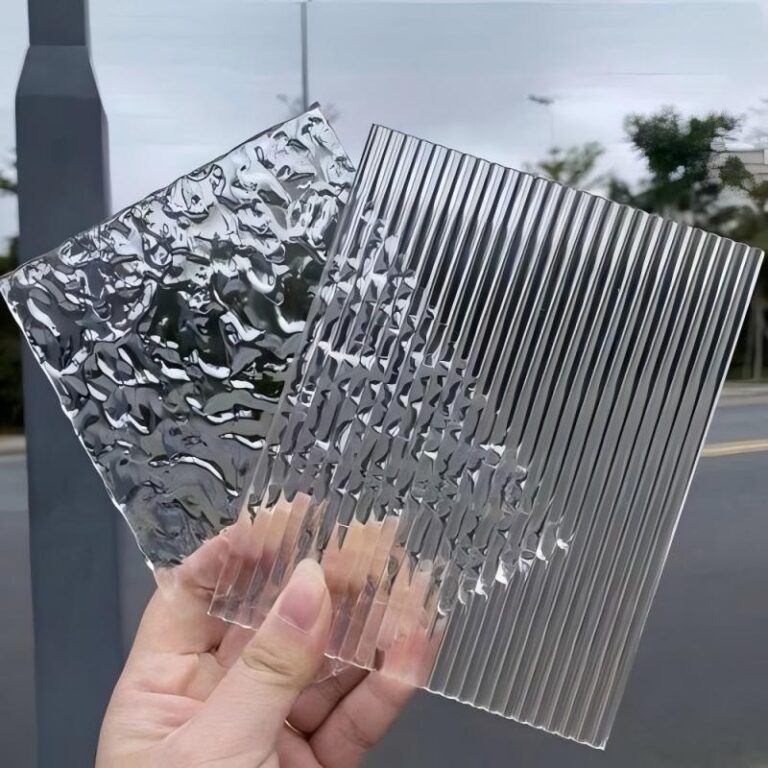

Intelligent light effect management

The acrylic lampshade using German Evonik light diffuser technology can convert LED point light sources into surface light sources, increasing light uniformity by 40%. Comparative tests show that the illumination uniformity of acrylic lamps is 32% higher than that of resin lamps at the same power.

The breakthrough advantage of material science

Extreme tolerance of -40℃~90℃

Acrylic sheets tested by ASTM D638 have a heat deformation temperature of 95℃ and a low-temperature brittle point of -40℃. The China Academy of Building Research has confirmed in experiments that they can work continuously for 2000 hours without deformation in an environment of -30℃ in Harbin and 48℃ in Turpan.

UV protection and long-term color retention

The VH001 anti-ultraviolet coating developed by Mitsubishi Chemical of Japan makes the color fastness of acrylic lampshade reach level 8, and the color difference value ΔE<1.5 after 10 years of outdoor use.

Comprehensive upgrade of safety performance

Flame retardant grade reaches V-0 standard

According to the UL94 vertical combustion test, the acrylic sheet with flame retardant can self-extinguish within 2 seconds after contact with the fire source, and the smoke density index is <15 (NFPA 258 standard), which is particularly suitable for public spaces such as shopping malls and hotels.

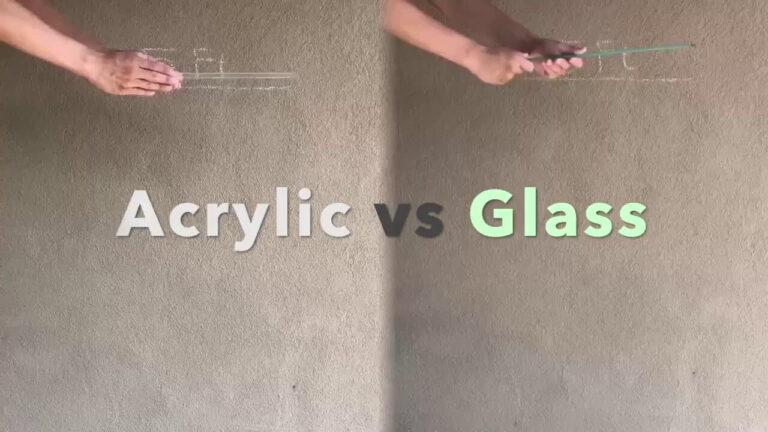

Strength is 20 times higher than glass

The impact test of the School of Materials Science and Engineering of Tsinghua University shows that 3mm thick acrylic sheet can withstand 50J impact energy, which is 22 times that of glass of the same thickness. After breaking, it forms blunt-angle particles, which greatly reduces the risk of accidental injury.

The core value in decoration practice

- 5 mainstream style adaptation solutions

- Minimalist style: 8mm ultra-thin flat panel lamp is recommended

- Industrial style: bare frame splicing structure is optional

- New Chinese style: carved pattern translucent board

- Light luxury style: titanium-plated metal trim (Versace Home latest series)

- Children’s room: food-grade color diffuser board (EN71-3 safety certification)

- Installation efficiency increased by 300%: Compared with the traditional lamp installation process, the Yake snap-on structure reduces the installation time of a single lamp from 45 minutes to 15 minutes. Data from the Guangzhou Baiyun International Convention Center project shows that the installation period of 3,200 lamps has been compressed by 58%.

Acrylic lights conomic and environmental analysis

- Life cycle cost reduced by 42%. The German TÜV certification report (No.: TUV-CL2023-087) shows that the 10-year maintenance cost of acrylic lamps is only 1/3 of that of glass lamps. Main savings:

- Cleaning frequency reduced by 60%

- Breakage rate reduced by 92%

- Light source replacement cycle extended by 2.8 times

- 100% recyclable environmental certification. Acrylic waste that has passed the EPEAT Silver certification can be converted into new raw materials through BASF’s chemical recycling technology, and the carbon footprint is reduced by 67% compared with virgin materials.

Professional Installation Guide (with data support)

- Load-bearing calculation model: Bolt bearing capacity ≥ 1.5 × lamp weight (ASME B18.2.1 standard) Example: The tensile strength of 6mm diameter expansion bolts in concrete reaches 240kgf

- Thermal management specifications: Lamp surface temperature control formula: Tmax=0.8×(Tg-20℃) Where Tg is the glass transition temperature of the material

Industry authoritative certification reference

- US UL 1598 safety certification

- EU EN 60598-1 lighting standard

- China GB 7000.201-2008 General requirements for lamps

- Japan JIS C 8105-1 electrical safety specifications

FAQs of Acrylic Lights

1. Are acrylic lights suitable for outdoor use?

Yes. With -40℃ to 90℃ temperature tolerance and UV-resistant coatings (ISO 105-B02 certified), they maintain ΔE<1.5 color difference for 10+ years outdoors.

2. How does acrylic compare to glass in light diffusion?

Acrylic achieves 92% transmittance with 40% better uniformity than glass through nano-structured diffusion layers

3. Do acrylic lights save long-term costs?

10-year maintenance costs 67% lower than glass, with 92% lower breakage rates

Conclusion of Acrylic Lights

From the landscape lighting of the Burj Khalifa in Dubai to the signage system of Beijing Daxing Airport, acrylic lamps are reshaping the light environment of modern buildings. Its breakthrough material properties, revolutionary optical design and significant economic benefits make it the preferred lighting solution in the smart era. When you plan your next space renovation, you may wish to log in to the International Association of Lighting Design official website to obtain professional solutions, or refer to the latest case library of Architectural Digest to discover the infinite possibilities of acrylic lamps.