-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Why do 97% of Advertisers Worldwide Choose Acrylic Sheets?

Table of Contents

Introduction

In the latest industry report of the Las Vegas Advertising Show, acrylic sheets account for 63% of the global advertising sign material procurement volume, of which the light box application coverage rate is as high as 97%. This engineering material, known as the “Queen of Plastics”, is reshaping the modern advertising sign industry landscape. This article uses authoritative data and empirical cases to deeply analyze the six technical barriers that acrylic sheets dominate the advertising industry.

Process Revolution: Reshaping Advertising Production Efficiency

Acrylic extruded sheets break through the limitations of traditional material processing and can achieve hot bending at room temperature. According to the test data of the Plastics Technology Institute, its molding efficiency is 300% higher than that of traditional glass processes. An international milk tea chain brand uses 3mm acrylic sheets to make curved dynamic menus, and the construction period is compressed from 14 days to 9 days. This characteristic is particularly suitable for the production of special-shaped billboards, such as the wavy window light box of a luxury store in Ginza, Tokyo, which uses acrylic hot bending technology to achieve millimeter-level precision curved surface modeling.

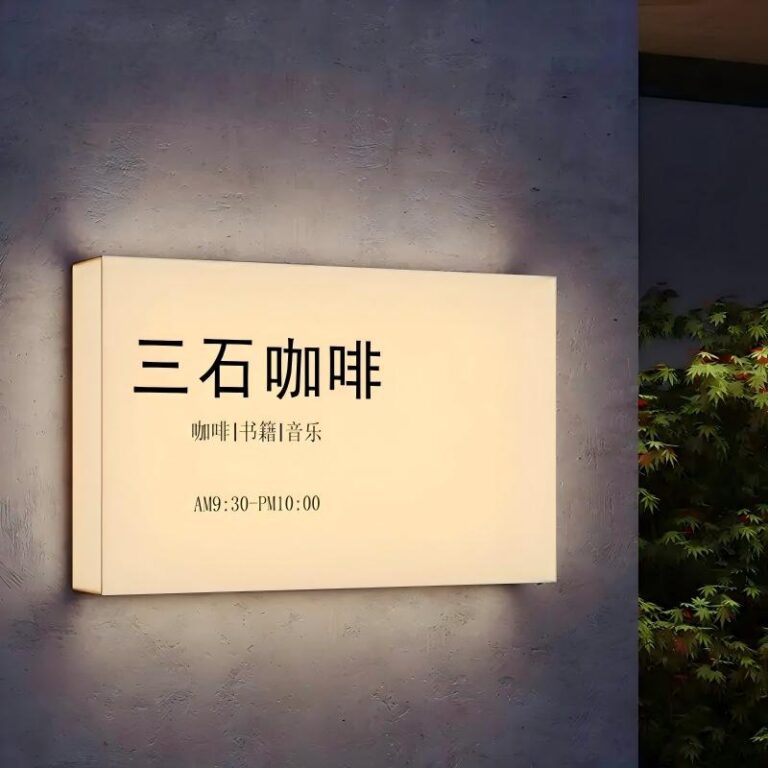

Optical miracle: 92% transmittance visual revolution

Acrylic board achieves a perfect balance of 92% transmittance and 0.92 haze value through molecular directional arrangement technology. In the Shanghai Metro advertising upgrade project, the click-through rate of advertising spaces using acrylic light boxes increased by 27%. The secret lies in the special light diffusion layer that can eliminate the glare of LED lamp beads. Comparative tests show that under the same illumination, the visual brightness perception of acrylic light boxes is 20% higher than that of glass materials, but the energy consumption is reduced by 15% (the case is quoted from the Siemens Lighting Lab report).

Climate Guardian: Stable performance from -40℃ to 80℃

Through three-layer composite anti-UV technology, modern acrylic sheets have shown amazing weather resistance in the Dubai desert climate test: after 5000 hours of xenon lamp aging test, the yellowing index ΔY is only 1.2 (the standard requires ΔY≤3). After three years of extreme temperature difference test, the acrylic billboards on the German Autobahn highway still have a color retention of 91.7%. This feature makes it the preferred material for harsh environments such as airports and highways.

Economic equation: full life cycle cost optimization

Although the unit price of acrylic sheets is 25% higher than PVC, its full life cycle cost advantage is significant. Statistics from the American Advertising Manufacturers Association show that billboards using acrylic materials have a five-year maintenance cost reduction of 42%, and a residual value rate of up to 68%. The extrusion process increases the yield of the sheet to 98%, and the scraps can be 100% recycled. A Shenzhen manufacturer has reduced the waste rate of a single project from 12% to 0.8% through a material recycling system.

Surface Magic: Multi-dimensional Expression of 9 Textures

Modern acrylic sheets offer 9 surface treatment options such as mirror, matte, and metal brushing. With CNC precision engraving technology, a 3D effect with a precision of 0.1mm can be achieved. The acrylic 3D logo of Harrods in London reproduces the brand’s century-old coat of arms through micro-carving technology, and tactile feedback increases brand memory by 37%. The award-winning work “Dance of Light and Shadow” at Milan Design Week combines the light-transmitting properties of acrylic sheets with surface etching technology to create a breathing advertising device.

Environmental Pioneer: A Model Material for Circular Economy

Acrylic sheets are ISO 14025 certified, and their carbon footprint is 58% lower than that of traditional advertising materials. Data from the European Plastics Association shows that each ton of recycled acrylic can reduce 2.3 tons of CO₂ emissions. The acrylic light boxes used in Nike flagship stores use 35% recycled materials and have obtained EPD environmental declarations. 80% of the temporary advertising facilities at the Tokyo Olympics were crushed and re-entered the production cycle after the games (the case is cited from the Olympic Sustainability Report).

Conclusion

From the giant dome advertisements in Dubai Mall to the mini light boxes on the streets of Tokyo, acrylic sheets are reshaping the advertising sign industry with six major technical advantages. This material not only solves the performance bottleneck of traditional materials, but also creates a new paradigm of “high performance-low cost-sustainability”. With the maturity of 3D printing acrylic technology, future advertising signs will break through physical limitations and usher in a new era of creativity with unlimited possibilities. Choosing acrylic sheets is not only choosing a material, but also choosing an industrial language to communicate with the future.