-

Xinqi Development Zone, Leliu, Foshan, Guangdong

OEM Acrylic Sheet Manufacturing to Solve Production Problems

Table of Contents

The Problem: Finding a Reliable Acrylic Sheet Manufacturer

Are you tired of dealing with:

- Low quality acrylic sheets that yellow too fast?

- Late deliveries that hold up your production?

- High costs eating into your profit margins?

- No customization options for your special needs?

Many businesses face these big problems when looking for acrylic sheet suppliers. You need a partner who understands your needs and can deliver top quality products on time.

Why These Problems Hurt Your Business

When you can’t get the right acrylic sheets:

- Your customers get mad about delays

- Your team gets stressed trying to fix problems

- You lose money on wasted materials

- Your brand looks bad with poor quality products

- Your growth stops because you can’t scale up

This is why finding the right is so important for your success.

The Solution: Our OEM Acrylic Sheet Manufacturing

We make custom acrylic sheets that solve all these problems:

- 100% virgin PMMA for the best quality

- On-time delivery you can count on

- Custom sizes and colors for your exact needs

- Factory direct pricing to save you money

- Expert support to help you choose the right product

Let’s see how our acrylic sheets can help your business grow!

Our Acrylic Sheet Types

| Type | Thickness Range | Best Uses | Special Features |

|---|---|---|---|

| Clear Acrylic | 1mm – 85mm | POP displays, Store fixtures | High optical clarity, UV resistant |

| Colored Acrylic | 2mm – 10mm | Signage, Retail displays | 20+ color options, Custom colors available |

| Frosted Acrylic | 3mm – 12mm | Privacy panels, Light diffusion | Elegant finish, Light dispersion |

| Mirror Acrylic | 1mm – 6mm | Displays, Safety mirrors | Lightweight, Shatter-resistant |

| Custom Cut Acrylic | Any size | Any application | Cut to your exact specs |

Why Our Acrylic Sheets Are Better

1. High Quality Raw Materials

Our acrylic sheets are made with 100% virgin PMMA (polymethyl methacrylate). This means:

- No yellowing over time

- Better clarity than glass

- More strength for your products

- Longer life for your applications

2. Custom Manufacturing Options

We can make acrylic sheets that fit your exact needs:

- Custom sizes from small to large sheets

- Custom colors to match your brand

- Custom thicknesses from 1mm to 85mm

- Custom finishes (glossy, matte, textured)

3. OEM Manufacturing Benefits

As your OEM partner, we offer:

- Your logo on products and packaging

- Your design specs followed exactly

- Your quality standards met or exceeded

- Your delivery schedule respected

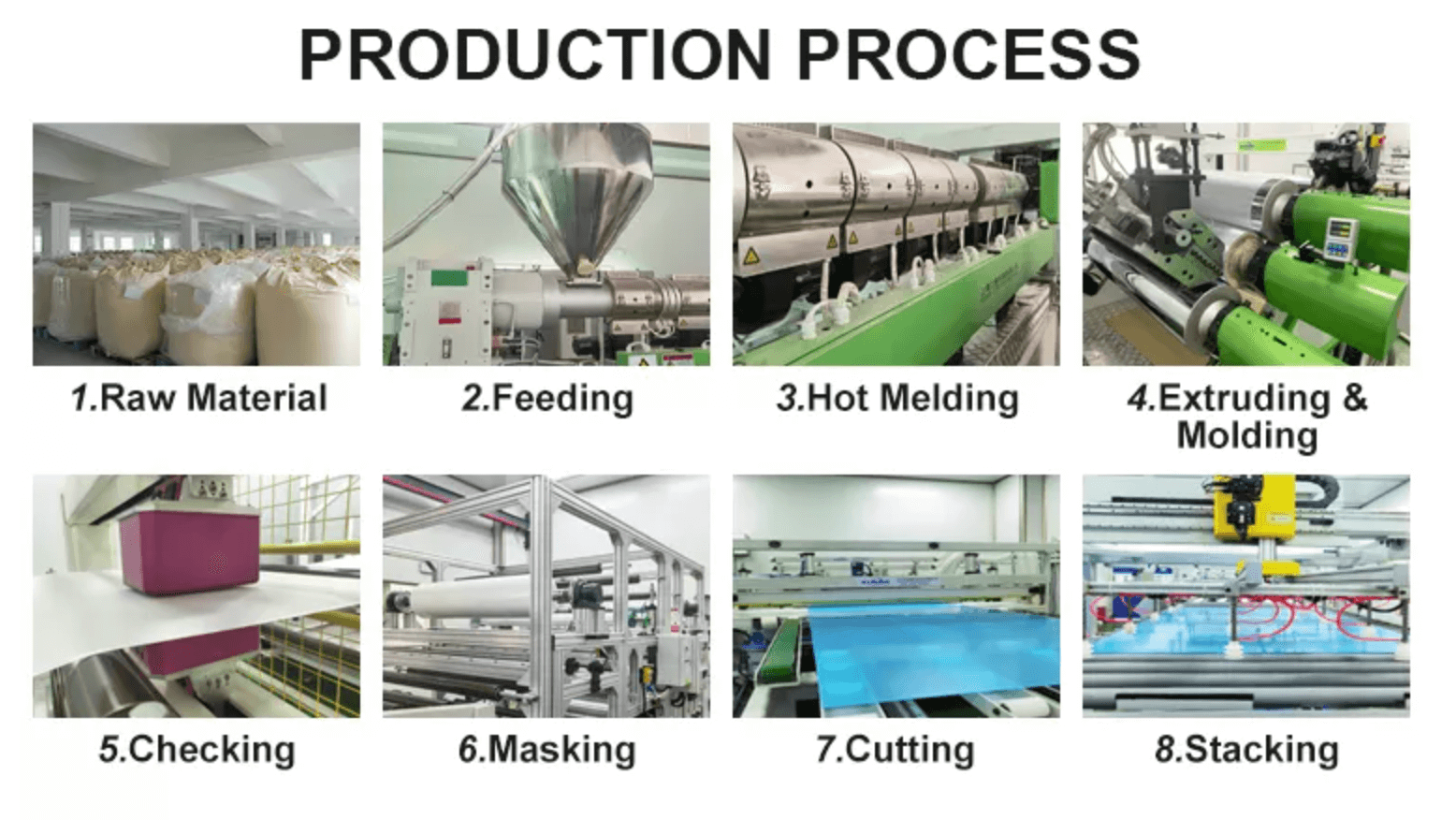

Our Manufacturing Process

Our factory uses the best methods to make your acrylic sheets:

- Raw material selection – Only premium PMMA

- Sheet casting – For the best optical quality

- Extrusion – For cost-effective production

- Quality testing – Every sheet checked

- Protective masking – Paper or film protection

- Custom cutting – To your exact size needs

- Packaging – Safe for shipping anywhere

Applications for Our Acrylic Sheets

Our customers use our acrylic sheets for many different things:

- Retail displays and store fixtures

- Signage and menu boards

- Furniture and home decor

- Architectural elements and room dividers

- Protective barriers and shields

- Light fixtures and LED displays

- Medical equipment components

- Art installations and picture frames

How to Order Your Custom Acrylic Sheets

Getting started with us is easy:

- Tell us what you need – Size, color, thickness, quantity

- Get a fast quote – Usually within 24 hours

- Approve your sample – We’ll send samples to check

- Place your order – Simple and straightforward

- Receive your sheets – On time, every time

Frequently Asked Questions

What is the smallest acrylic sheet I can order?

We can make sheets as small as you need, but standard sizes start at 12″ x 12″. Custom cut acrylic sheets are available for any size you need.

How do you package acrylic sheets for shipping?

All our sheets come with protective masking on both sides and are packed in sturdy boxes or crates depending on size and quantity.

What is the difference between cast and extruded acrylic?

Cast acrylic has better optical quality and is easier to fabricate. Extruded acrylic is more cost-effective and has better tolerance. We offer both types depending on your needs.

Can you match a specific color for my brand?

Yes! We can match any Pantone color or physical sample you provide. Our colored acrylic sheets come in standard colors or custom colors.

What is your minimum order quantity?

For standard sizes and colors, our MOQ is 10 sheets. For custom colors or sizes, please contact us for specific MOQ information.

Compare Acrylic vs. Other Materials

| Feature | Our Acrylic | Glass | Polycarbonate |

|---|---|---|---|

| Weight | Light (50% of glass) | Heavy | Medium |

| Impact Resistance | Good | Poor | Excellent |

| UV Resistance | Excellent | Excellent | Good with coating |

| Clarity | 92-95% | 90% | 88% |

| Fabrication Ease | Very easy | Difficult | Moderate |

| Cost | Medium | High | High |

Technical Specifications

Our clear acrylic sheets meet or exceed these specifications:

- Light transmission: 92-95%

- Impact resistance: 16-20 times stronger than glass

- Heat resistance: Up to 160°F (71°C)

- Chemical resistance: Excellent against many household chemicals

- Weather resistance: No significant yellowing for 10+ years

- Thermal insulation: 20% better than glass [^5]

Ready to Solve Your Acrylic Sheet Problems?

Stop dealing with poor quality and late deliveries! Contact us today to discuss your OEM acrylic sheet needs.

- Phone: +8613928561594

- Email: [email protected]

- Website: https://bestacrylicsheet.com

- Request a Quote: Get Your Custom Quote