-

Xinqi Development Zone, Leliu, Foshan, Guangdong

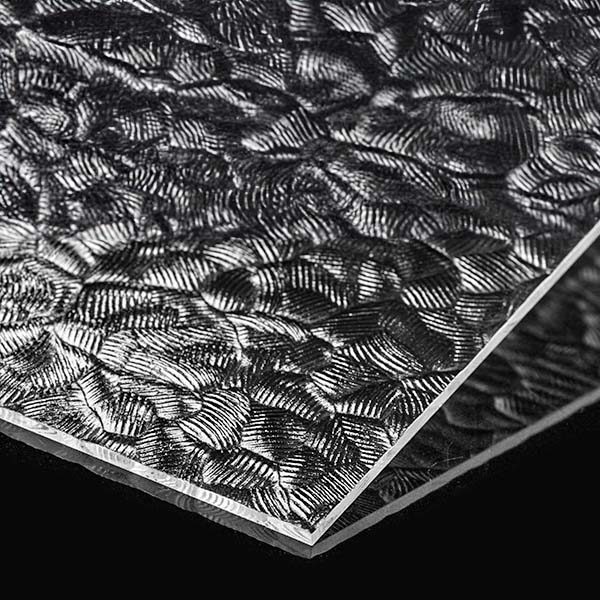

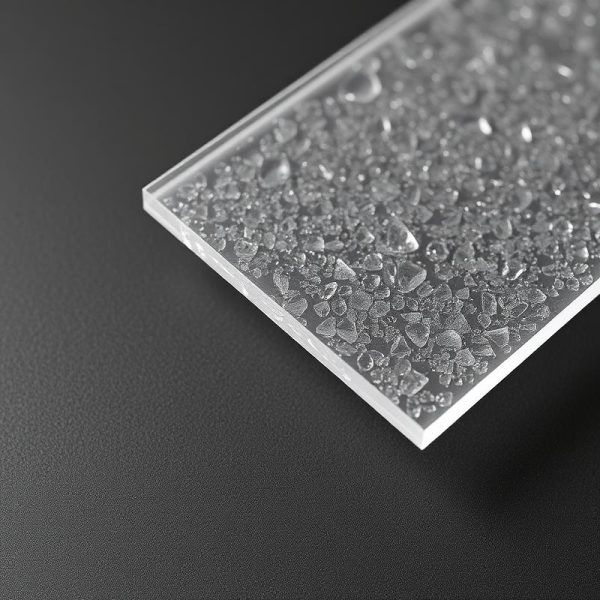

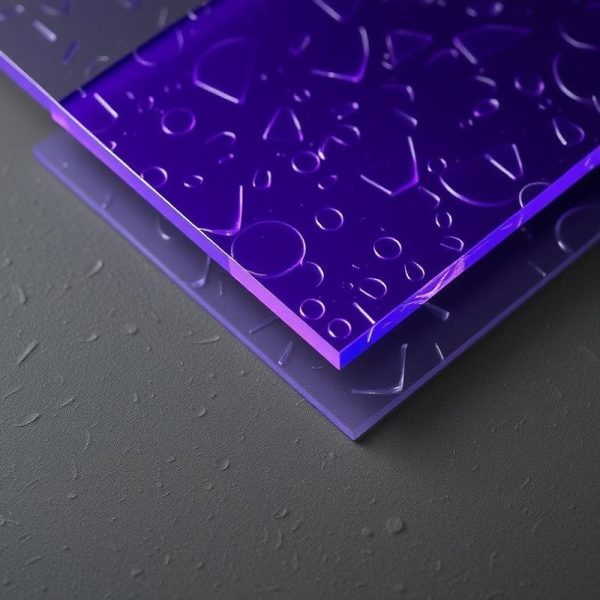

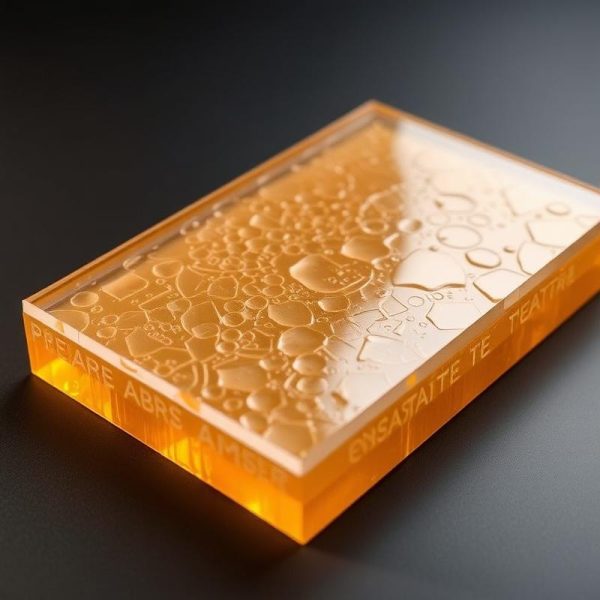

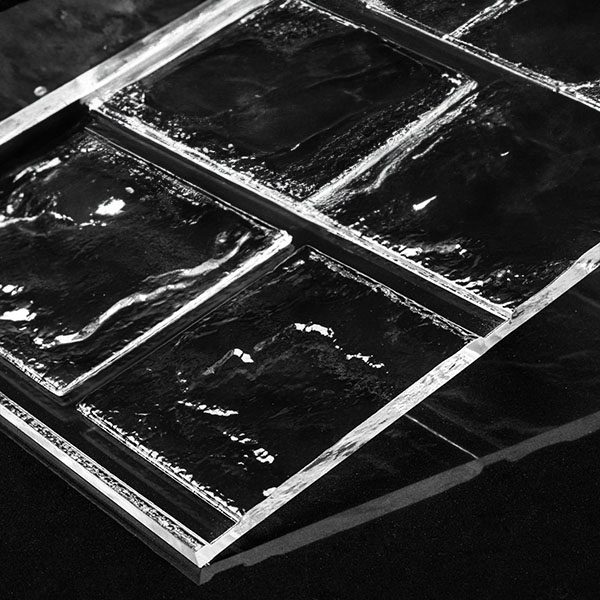

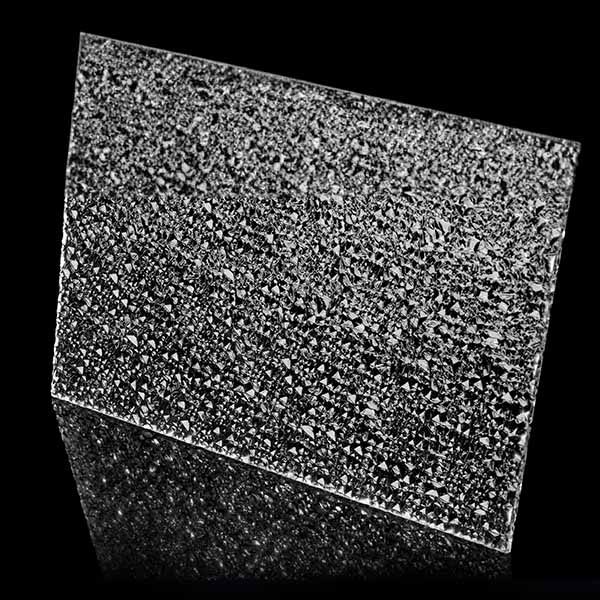

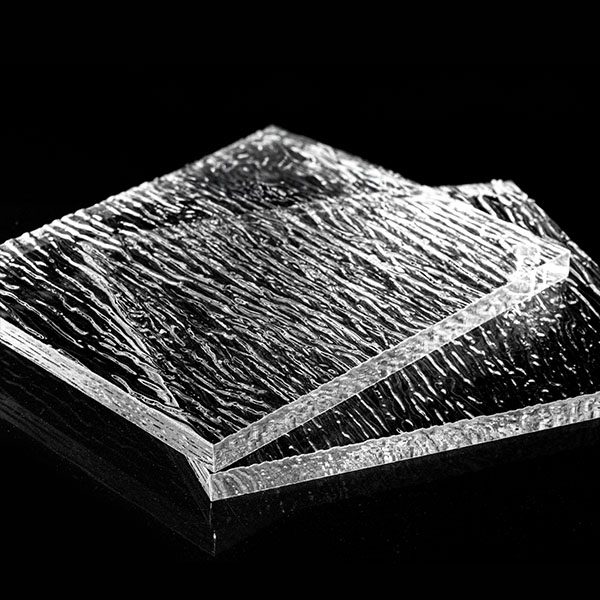

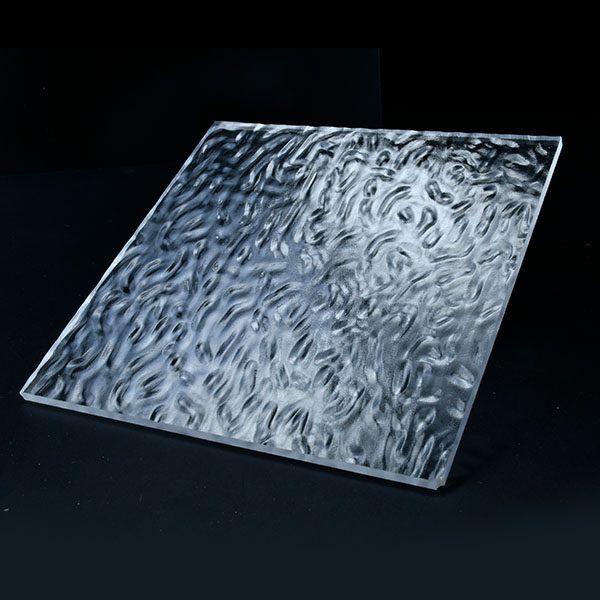

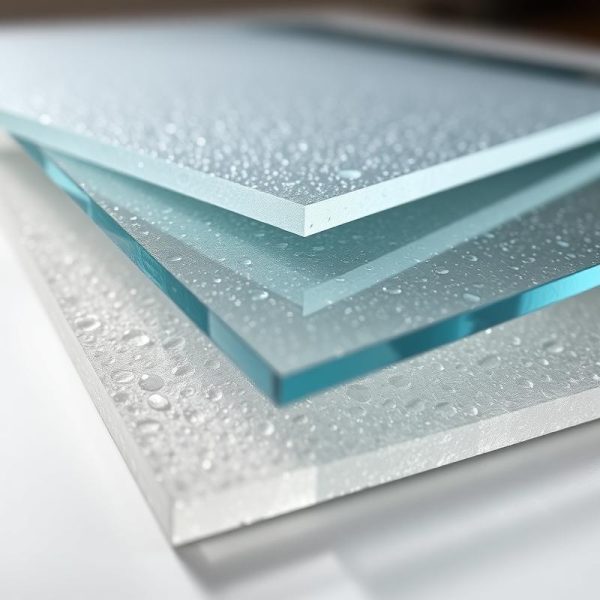

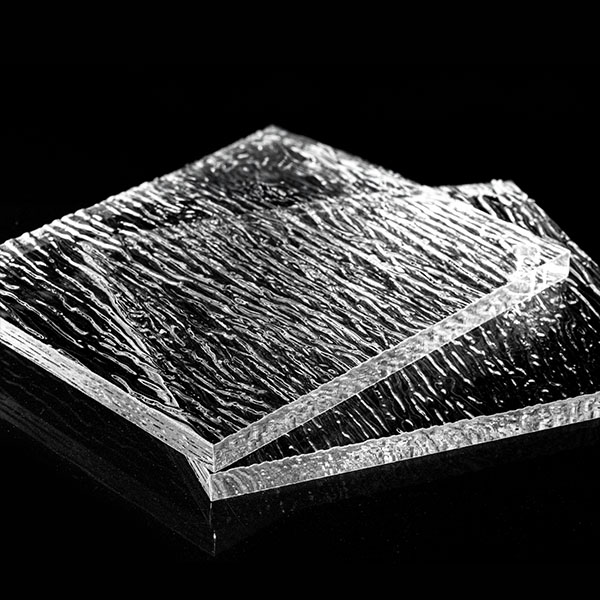

Extruded Textured Acrylic Sheet

What Is It?

This is a flat sheet made of acrylic plastic. It has a special top that feels bumpy or smooth. You can cut it, bend it, and make things with it. Our comes in many colors and sizes.

Why People Like It

- Looks nice – Comes in glossy or matte finish

- Strong – Does not break easy

- Light – Easy to carry and put up

- Tough – Stands up to sun and rain

- Safe – Does not make bad smoke if it burns

How Big Can You Get It?

| Size | What You Can Make |

|---|---|

| 24″x48″ | Small signs, Desk tops |

| 48″x96″ | Big signs, Wall covers |

| Custom size | Your size – Just ask! |

How Thick Can You Get It?

Our extruded acrylic sheets come in many thicknesses:

- 1/16″ (1.5mm) – Thin like a coin

- 1/8″ (3mm) – Like a stack of 3 coins

- 1/4″ (6mm) – Like a pencil

- 3/8″ (9.5mm) – Like your little finger

- 1-20mm, any thickness is available, let us know your requirement

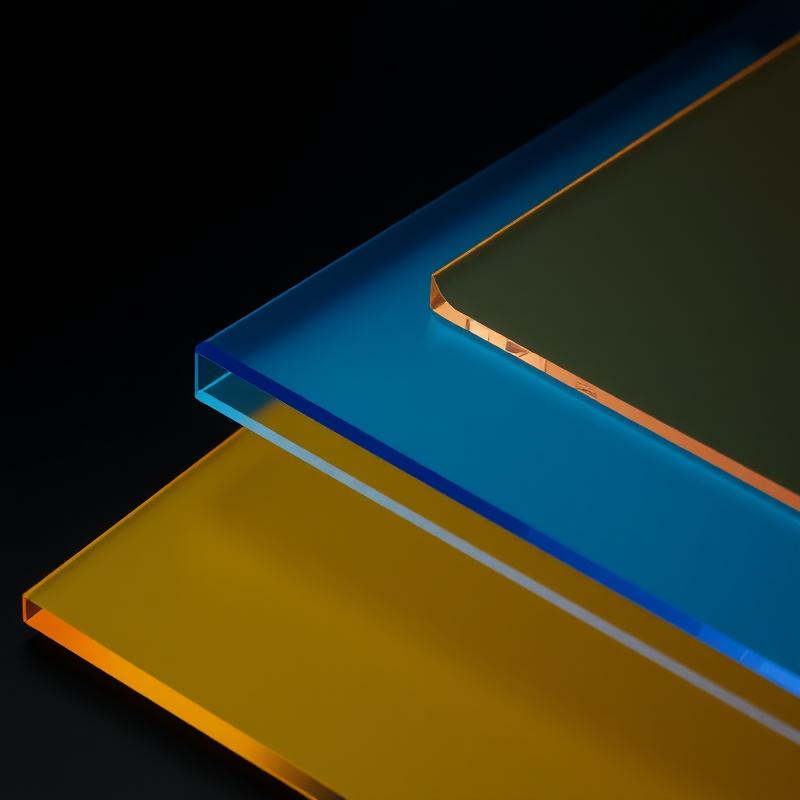

What Colors Can You Get?

- Clear acrylic sheet – See through it

- Black acrylic sheet – Dark like night

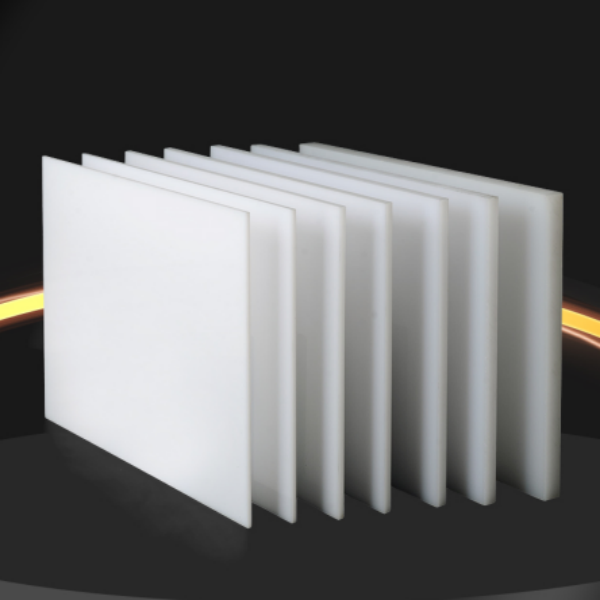

- White – Like snow

- Grey (#2074) – Like a rain cloud

- Many more fun colors!

Specification

- Premium Raw Materials: 100% virgin material quality grade, no recycled content

- Superior Optical Clarity: Crystal clear options with 93-98% light transmission

- Extensive Color Range: Over 200 colors including transparent, translucent, opaque, and fluorescent options

- Custom Sizing: Cut-to-size service available to your exact specifications

- Wholesale Pricing: Competitive bulk pricing for large volume orders

- Fast Production: Multiple workshops with over 1000 molds ensure quick turnaround

- Technical Support: Expert consultation on material selection and applications

What Can You Make?

- Store Signs – Looks nice in shops

- Art – Cut shapes with a laser

- Walls – Makes rooms look nice

- Guards – Keeps things safe

- Toys – Make fun stuff at home

Why Is It Good?

- Keeps Sun Out – Blocks 98% of bad sun rays

- Not Hot or Cold – Works from -40°C to +100°C

- Quiet – Keeps noise down

- Stays Nice – Does not turn yellow easy

- Safe – Can touch food

What Comes With It?

Each acrylic sheet has paper or film on both sides. This keeps it safe until you use it. Just peel off when you are ready!

How to Use It

- Draw what you want to make

- Cut the sheet (with laser or saw)

- Bend it if you need to (with heat)

- Glue parts if you need to

- Enjoy your new thing!

Want to know more? Call us now or shop our full selection of acrylic sheets!

10 things to note when purchasing products from China

Help Center

Have a query? Please check this question and answers

Yes, we use 100% premium-grade virgin acrylic (PMMA) with no recycled content, ensuring superior clarity, UV resistance, and long-term durability for all products.

We are ISO 9001 certified for quality management and comply with REACH/SGS environmental standards. Custom certifications (e.g., FDA for food-grade acrylic) can be provided upon request.

Standard items: 7-10 days. Custom orders: 12-18 days depending on complexity. Rush orders can be discussed.

Yes. We provide CNC cutting, laser engraving, thermoforming, and edge polishing. Send us CAD files/DXF designs for instant quoting. Minimum order: 10 pieces per design.

Standard thickness: 1mm-15mm. Colors: Clear, frosted, 16+ transparent colors, and custom Pantone matching (MOQ 500kg). Tolerance: ±0.2mm.

We provide 3 free A4-sized samples. Customers cover DHL/UPS shipping costs. Sample lead time: 72 hours.

Color variations in acrylic sheets can occur due to several factors, including:

Production batch differences: Slight changes in pigment concentration or raw materials between batches.

Manufacturing conditions: Variations in temperature, pressure, or curing time during production.

UV exposure: Prolonged sunlight exposure may cause fading or color shifts.

Cutting/processing: Heat generated during cutting or machining can alter surface color temporarily.

Store in a cool, dry, UV-protected environment away from direct sunlight.

Keep protective films intact until installation to avoid scratches or chemical reactions.

Avoid stacking sheets with uneven pressure, which may cause stress-induced discoloration.

While custom colors reduce risks, absolute consistency is challenging. Always request a pre-production sample and agree on a tolerance range with the supplier.