-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Polycarbonate vs Acrylic : Which Should You Choose

Table of Contents

Introduction

In the world of transparent plastics, acrylic and polycarbonate are two popular materials, but their performance differences are often confusing. According to statistics from the Plastics Industry Association, these two materials account for more than 60% of the global transparent plastic market, but the cost waste caused by incorrect material selection is as high as hundreds of millions of dollars each year. This article will deeply analyze the eight core differences between the two, combining authoritative data and external link resources to help you make scientific decisions based on project needs.

Impact strength: the “bulletproof” property of polycarbonate

The impact strength of polycarbonate is more than 30 times that of acrylic (data source: SABIC Materials Laboratory), and the toughness of its molecular chain makes it bend instead of break when impacted. For example, a 3mm thick polycarbonate sheet can withstand an impact energy of 5 joules, while acrylic will break directly under the same conditions (test standard: ASTM D256). Therefore, polycarbonate is almost monopolized in the field of safety protection such as riot shields and safety helmets.

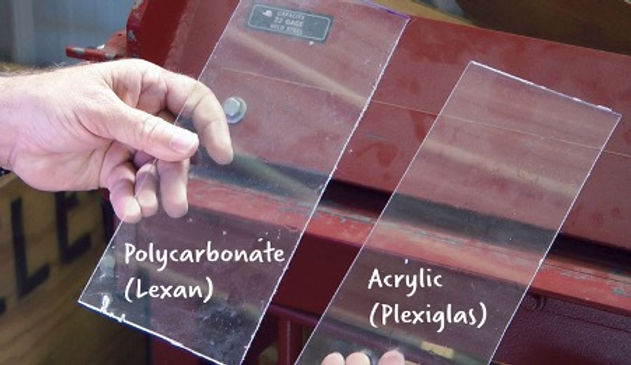

Optical performance: acrylic’s “crystal” level light transmittance

Acrylic has a light transmittance of 92% (close to 93% of glass), while polycarbonate is only 88%. This difference is particularly critical in optical devices: the imaging distortion rate of acrylic lenses is less than 0.1%, while polycarbonate lenses may produce a visual error of 0.5%. Therefore, scenes such as museum display cabinets and high-end lighting fixtures prefer acrylic.

Temperature resistance limit: the life and death line in high temperature environment

The glass transition temperature (Tg) of polycarbonate is 147°C, which is 42°C higher than the 105°C of acrylic (data source: UL Prospector material database). In high temperature scenes such as parts under the hood of a car, acrylic may deform in a continuous 80°C environment, while polycarbonate can work stably up to 120°C.

Surface hardness: the “scratch-resistant” advantage of acrylic

According to the Mohs hardness test, the hardness of acrylic is level 4-5 (close to aluminum), while polycarbonate is only level 3 (close to copper). This means that the surface of polycarbonate is easily scratched by hard objects such as keys, while acrylic can withstand daily friction. However, polycarbonate can increase its surface hardness to level 8 through a coating process.

Chemical stability: Material competition in acid-base environment

Polycarbonate has excellent tolerance to weak acids, greases and alcohols, but is easily corroded by strong alkalis (such as ammonia water); acrylic is sensitive to strong acids (such as concentrated sulfuric acid), but can resist diluted alkali solutions. For example, in laboratory fume hood applications, polycarbonate needs to be coated with an additional protective layer to deal with acid and alkali splashes (case reference: Corning Chemical Resistance Guide).

Economic efficiency: The cost gap can reach 300%

The price of acrylic raw materials is about $3.5/kg, while that of polycarbonate is as high as $6.8/kg (ICIS Chemical Market Report 2023). Taking the production of a 2m×1m advertising light box as an example, the cost of using acrylic is about $120, while the polycarbonate version costs $380. But please note: the durability of polycarbonate can reduce long-term replacement costs.

Processing technology: the art of “hot bending” of acrylic

Acrylic can be thermoformed at 150°C, while polycarbonate requires more than 180°C. This feature makes acrylic easier to make complex curved shapes, such as the spiral staircase handrails of the Apple Store. However, polycarbonate has better injection molding fluidity and is suitable for the production of structural parts such as precision gears.

Environmental performance: the truth behind the recycling code

Acrylic (recycling code #7 “OTHER”) is currently difficult to recycle on a large scale, while polycarbonate (code #7 but contains BPA) faces regulation due to health disputes. However, Covestro has launched BPA-free polycarbonate and acrylic companies are exploring bio-based PMMA technology.

FAQ about Polycarbonate vs Acrylic

Which one is more impact-resistant, acrylic or polycarbonate?

The impact strength of polycarbonate is more than 30 times that of acrylic, and it is widely used in high-intensity scenes such as riot shields and safety helmets.

Which material has a light transmittance closer to glass?

Acrylic has a light transmittance of 92% (close to 93% of glass), which is suitable for applications with high clarity requirements such as optical lenses and high-end display cabinets.

Which material should be selected in high-temperature environments?

Polycarbonate has a temperature resistance of 147°C, which is 42°C higher than acrylic, and is more suitable for high-temperature environments such as automotive engine parts.

Which material is more scratch-resistant?

Acrylic has a higher surface hardness (Mohs 4-5) and is more scratch-resistant for daily use; polycarbonate needs to be coated to improve scratch resistance.

Conclusion

There is no absolute winner in the contest between acrylic and polycarbonate:

- Choose acrylic: When the project requires high light transmittance, surface hardness, low cost or complex shape (such as retail display, optical lens).

- Choose polycarbonate: When impact resistance, temperature resistance or chemical stability are key requirements (such as industrial protection, medical equipment).

Only by accurately quantifying the requirements through ISO standard tests can the value of the material be maximized. If you need a customized material selection plan, please visit Sanyu Acrylic for professional support.