-

Xinqi ontwikkelingszone, Leliu, Foshan, Guangdong

Acrylic Thickness for Displays: Avoid 3 Costly Errors

Abstract:

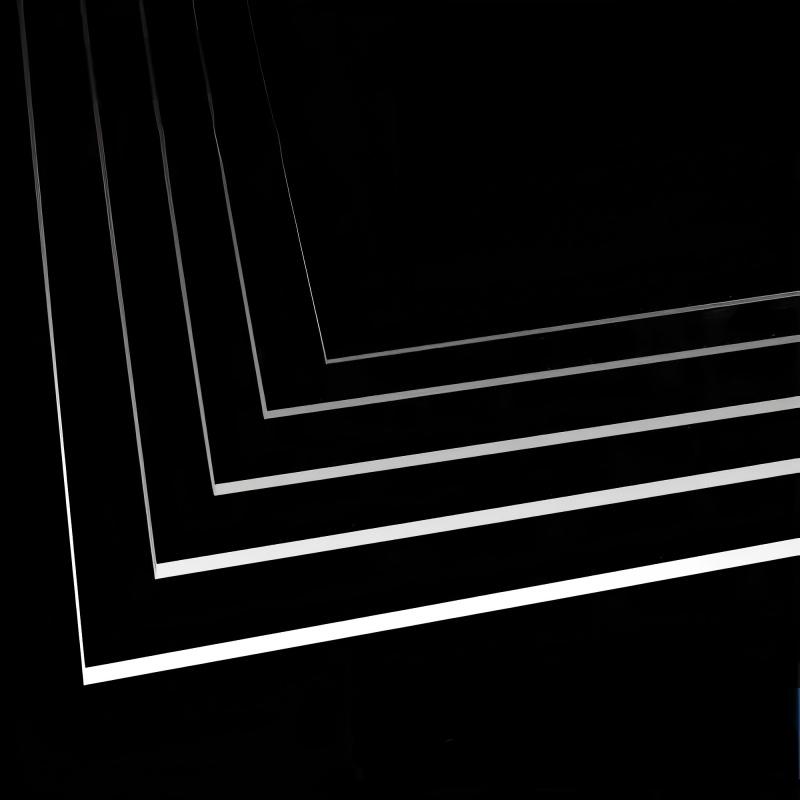

De dikte van acrylplaat is geen simpel getal. Het is een onzichtbaar skelet in ontwerpapplicaties, dat in stilte de belastbaarheid, vormvrijheid en levensduur van het werk bepaalt. Alleen door de juiste dikte te kiezen, kan creativiteit veilig landen.

Acryl (plexiglas/PMMA) is een magisch materiaal geworden voor ontwerpers om glas te vervangen, dankzij de kristalheldere transparantie, uitstekende weerbestendigheid en lichtheid. Echter, of een acrylplaat de ontwerpvisie perfect kan dragen, hangt af van de dikte speelt een doorslaggevende rol - het is als de ruggengraat van het materiaal, die de sterkte, flexibiliteit, het gewicht en de uiteindelijke functionele prestaties diepgaand beïnvloedt.

Dit artikel analyseert diepgaand hoe de dikte van acrylplaat de kernvariabele wordt in ontwerpapplicaties, van ultradunne behendigheid tot dikke volharding, en onthult de prestatiecode en gouden toepassingsregels achter verschillende diktebereiken.

1. Structurele sterkte: een kwalitatieve sprong van decoratie naar belastbaarheid

- Dunne platen (1-3 mm): Beperkte structurele sterkte, als "gaas in het ontwerp". Zwakke buig- en slagvastheid, alleen geschikt voor pure decoratieve bekleding, kleine modelafdekking, lichtgewicht displaystand en andere niet-drukdragende scènes. Gemakkelijk te vervormen of zelfs te barsten onder invloed van externe krachten.

- Middelgrote en dikke platen (4-10 mm): Een kwalitatieve sprong in sterkte, waardoor het een "multifunctionele ruggengraat" wordt. In staat om matige impact en continue belasting te weerstaan, bekwaam voor binnenwanden, meubelpanelen (bureaus, kastdeuren), middelgrote displayrekken, beschermhoezen en andere taken. Zoals opgemerkt door de American Plastics Industry Association (SPI), is dit diktebereik goed voor het hoogste percentage in commerciële binnentoepassingen, omdat het de beste oplossing biedt tussen sterkte en kosten.

- Dikke platen (11-50 mm+): Omgevormd tot "structurele bewakers", met een belastbaarheid en slagvastheid die vergelijkbaar is met glas. Ontworpen voor scenario's met hoge belasting: grote aquariumkijkvensters (die enorme waterdruk weerstaan), veiligheidsleuningen voor gebouwen, beschermhoezen voor zware apparatuur, permanente dragende werkbladen. De uitstekende prestaties worden vaak geverifieerd door strikte normen (zoals ASTM D792).

2. Optische prestaties: het spel tussen diepte en vervorming gegeven door dikte

- Dunne platen (1-3 mm): Extreme lichtheid zorgt voor optische vervorming die bijna nul is, en de doorlaatbaarheid kan 92% bereiken. Het is de eerste keuze voor uiterst nauwkeurige weergave (museumtentoonstellingsborden, observatievensters voor optische instrumenten) en het nastreven van absolute transparantie.

- Middelgrote dikke platen (4-10 mm): De doorlaatbaarheid is nog steeds uitstekend (ongeveer 90%-92%), maar naarmate de dikte toeneemt, kunnen de randen lichte visuele vervorming veroorzaken. Dit kan een zacht halo-effect creëren in lichtgevende letterpanelen en lichtgeleiderplaat toepassingen, waardoor het visuele niveau wordt verbeterd.

- Dikke platen (11-50 mm+): De "lange reis" van het licht veroorzaakt aanzienlijke randrefractie en interne verstrooiing. Hoewel het wat transparantie verliest, bereikt het een unieke esthetiek - het dikke gedeelte presenteert een kristalheldere "ijssteen" textuur, en de zijkant is zo helder als kristal na fijn polijsten, wat zeer geschikt is voor high-end toonbanken en kunstinstallaties.

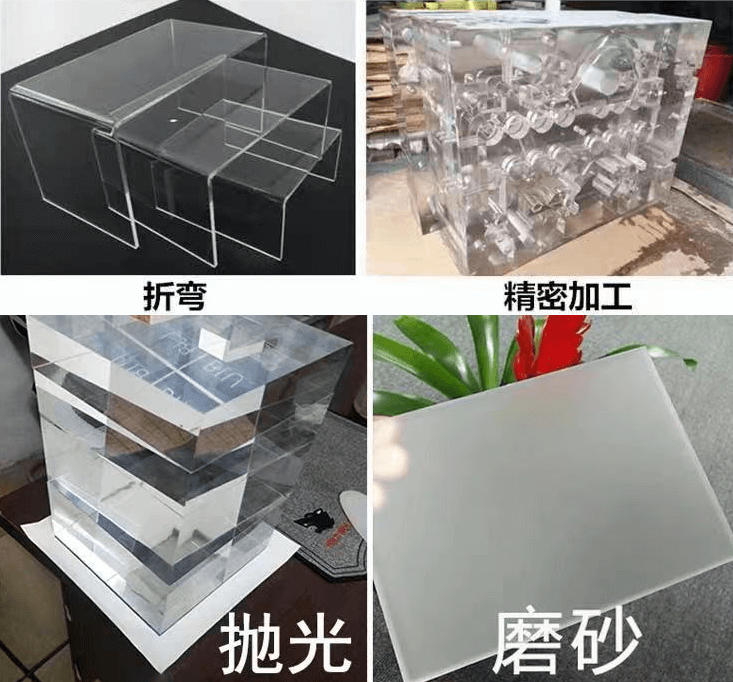

3. Warmbuigen en modelleren: de dikteboeien van flexibele grenzen

- Dunne plaat (1-3 mm): Het is het ideale canvas voor "warmbuigkunstenaars". De uitstekende flexibiliteit maakt het gemakkelijk om kleine radiusbuigingen en complexe gebogen oppervlaktemodellering te bereiken (zoals gebogen productdisplayhoezen en creatieve lichtbakken) bij lage temperaturen (ongeveer 150-160°C), waardoor het ontwerp een flexibele curve krijgt.

- Middelgrote en dikke plaat (4-10 mm): Warmbuigen vereist meer warmte-energie (160-180°C) en professionele apparatuurondersteuning, en kan gladde boogmodellering voltooien (zoals gebogen winkelborden en eenvoudige gebogen scheidingswanden). Een te kleine buigradius kan gemakkelijk spanningswitheid of zelfs barsten veroorzaken.

- Dikke plaat (11-50 mm+): Warmbuigen is bijna als een "stalen krijger", vereist uiterst professionele hogetemperatuurapparatuur (180°C+) en een langzaam proces. Meestal beperkt tot grote boog- of eenvoudige hoekbuiging (zoals een grote buitenbordbasis). Koude bewerking (snijden, graveren, ponsen) is het belangrijkste middel om vorm te geven.

4. Kosten en efficiëntie: de economische logica achter dikte

- Dunne plaat (1-3 mm): De laagste materiaalkosten, snelle verwerking (snijden, graveren, warmbuigen), laag energieverbruik, is budgetgevoelige projecten, kortetermijntoepassingen, snelle doorlooptijden economische keuze.

- Middelgrote en dikke plaat (4-10 mm): De kosten en verwerkingstijd zijn gematigd, waardoor de beste balans wordt bereikt tussen duurzaamheid, functionaliteit en kosten, en is de "kosteneffectieve koning" van de meeste commerciële projecten.

- Dikke plaat (11-50 mm+): De materiaalkosten zijn aanzienlijk gestegen, de verwerking (vooral snijden, ponsen, polijsten) vereist zware apparatuur, is tijdrovend en energie-intensief, en de installatie is ook ingewikkeld vanwege het gewicht. Het is een langetermijninvestering die streeft naar extreme duurzaamheid, structurele prestaties en een hoogwaardige textuur.

5. Installatie en onderhoud: de zwaargewicht uitdaging van dikte

- Dunne platen (1-3 mm): Ultralicht gewicht vereenvoudigt de installatie en gewone lijmen of kleine bevestigingsmiddelen kunnen worden gebruikt om te bevestigen. Het oppervlak is echter gemakkelijk te bekrassen en reiniging moet bijzonder voorzichtig zijn**. Langdurig buitengebruik is vatbaar voor veroudering en broosheid.

- Middelgrote en dikke platen (4-10 mm): Er zijn stabielere ondersteuningsstructuren en sterkere bevestigingen (zoals professionele acryllijm en metalen clips) vereist. De oppervlaktehardheid is verbeterd, de krasbestendigheid is beter, het onderhoud is relatief zorgeloos en de algehele duurzaamheid is uitstekend**.

- Dikke platen (11-50 mm+): Gewicht wordt de grootste uitdaging en de installatie moet vertrouwen op zware ingebedde onderdelen of stalen frameconstructies, en professioneel hijsen is vaak onmisbaar. Het oppervlak is het meest slijtvast en de winddruk- en slagvastheid zijn top, met de laagste onderhoudseisen en een extreem lange levensduur.

VI. Ontwerptaal en perceptie: visueel gewicht gevormd door dikte

- Dunne plank (1-3 mm): geeft een gevoel van "lichtheid, verfijning en moderniteit", heeft een sterk gevoel van verdwijning, en is geschikt voor het creëren van een transparante ruimte of het benadrukken van het tentoongestelde object zelf.

- Middelgrote dikke plank (4-10 mm): weerspiegelt een gevoel van "stabiliteit, betrouwbaarheid en kwaliteit". Het gematigde gevoel van aanwezigheid stelt het in staat om ruimtes te scheiden met behoud van visuele continuïteit, en is een universele keuze voor het creëren van een professionele zakelijke sfeer**.

- Dikke plank (11-50 mm+): geeft een sterke verklaring van "kracht, luxe en eeuwigheid". De zware randen en het kristalheldere blokgevoel zijn visueel extreem impactvol en worden de focus en symbool van macht in de ruimte.

De dikte van de acrylplaat is geenszins een koude numerieke parameter. Het is een liniaal van mechanische eigenschappen, een schakelaar van optische magie, een penseel van modelleringsgrenzen, een berekening van kosteneffectiviteit, een gewicht van installatie en onderhoud, en een vormgever van ontwerptaal. Van 1 mm dun als een cicadevleugel tot 50 mm dik als ijs, elke millimeter verschil herdefinieert in stilte de mogelijkheden van ontwerp en de kracht van de uiteindelijke presentatie.

Het begrijpen van de code van dikte is de sleutel tot het beheersen van de ultieme prestaties van acrylkenmerken - creativiteit wordt niet langer beperkt door het onbekende van materialen, maar bloeit veilig en briljant in de echte wereld met de steun van nauwkeurige berekeningen. Met een hoge acrylproductiecapaciteit en rijke specificaties biedt Sanyu Plastics solide ondersteuning voor elke nauwkeurige dikteselectie.