-

Xinqi Development Zone, Leliu, Foshan, Guangdong

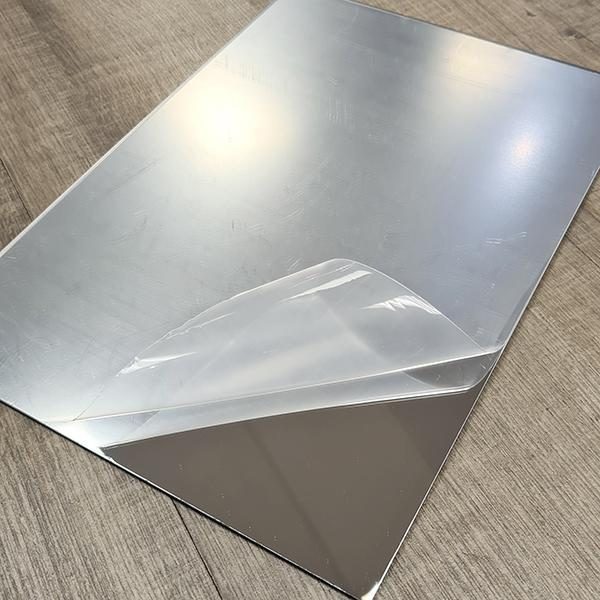

1mm Thin Mirror Acrylic Sheet 4X8

Shatter-Resistant Mirror Acrylic Sheet

Product Description:

| Property | Value/Description |

|---|---|

| Material | Acrylic (PMMA – Polymethyl Methacrylate) |

| Thickness | 1mm acrylic sheet is standard, 2-20mm are available |

| Sizes | 1250x2500mm is standard sheet size, custom size is available. We specialize in size orders to meet your exact needs. |

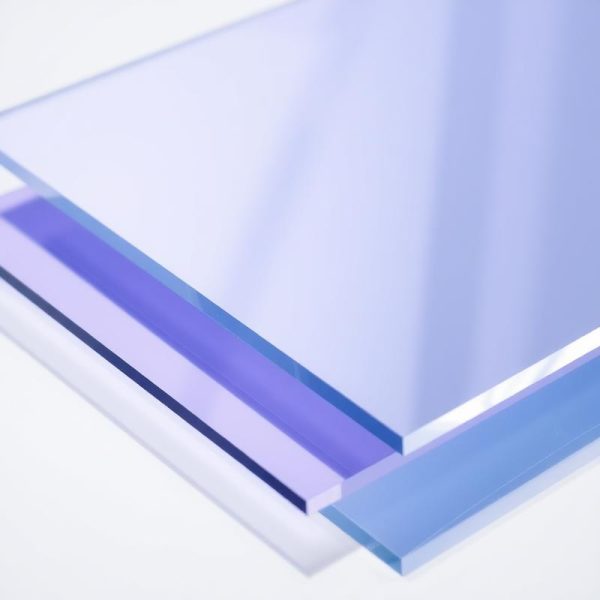

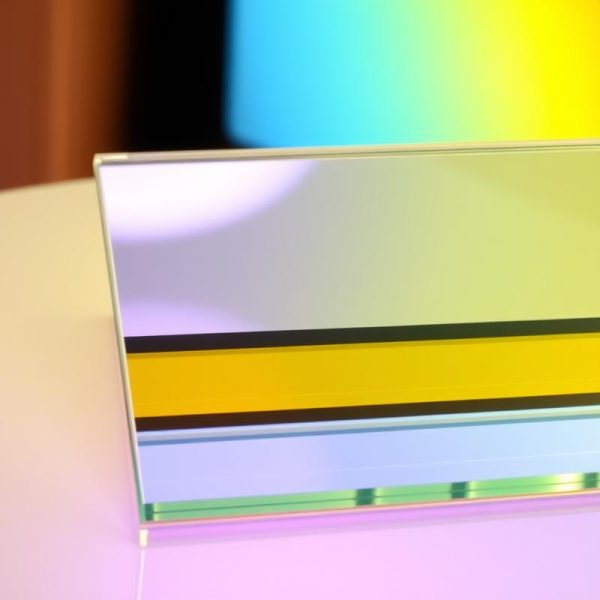

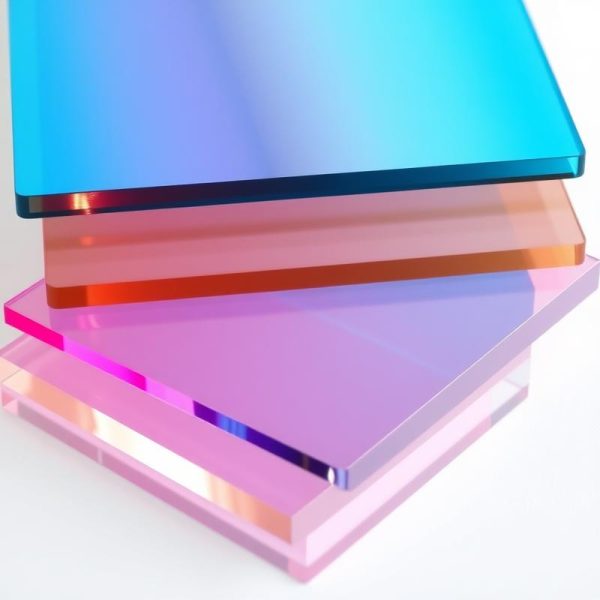

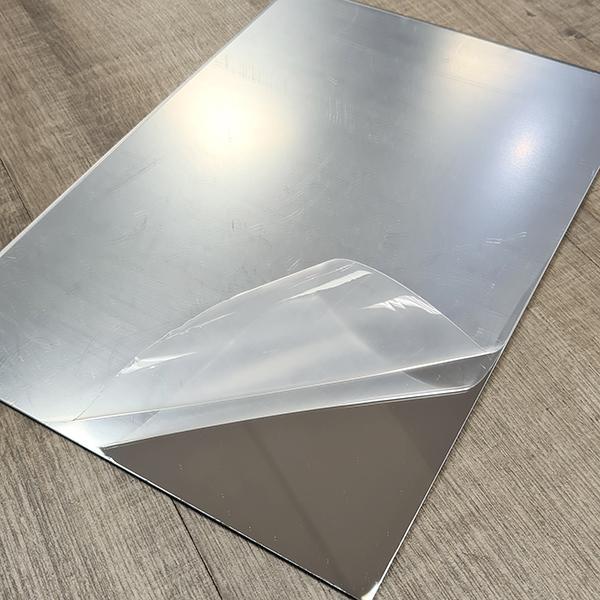

| Color | Standard silver mirror finish; gold mirror acrylic sheets and a variety of colors also available. |

| Finish | Glossy, reflective surface with protective film masking. |

| Backing | Opaque gray backing for protection and durability. |

| Applications | Ideal for: DIY projects, signage, decoration, displays, retail fixtures, and as an alternative to traditional glass mirrors. Perfect for building materials applications. |

| Fabrication | Easily cut, drilled, shaped, and polished. Suitable for laser cutting and engraving. |

Why Choose Sanyu Mirror Acrylic Sheets?

- Established in 1998, our acrylic manufacturing facility combines nearly three decades of craftsmanship with over 20 years of international distribution expertise.

- Your business growth is our priority – we partner with clients to develop mutually beneficial market expansion strategies.

- A dedicated support team of 200+ industry specialists stands ready to provide immediate technical assistance and customized solutions.

- Premium-grade materials sourced exclusively from Mitsubishi Chemical and Lucite International form the foundation of our product quality assurance.

- Optical clarity specifications:

- Transparent sheets: 94%+ light transmission efficiency

- Colored variants: UV-resistant formulation maintains chromatic stability for 8-10 years in outdoor applications

- Precision manufacturing guarantees thickness consistency within ±0.1mm tolerance parameters.

- Engineered performance characteristics include:

- Laser-cutting optimized composition

- UV printing compatibility

- Crack-resistant bonding properties

- Non-yellowing molecular structure

- Comprehensive quality management protocols monitor production chain integrity from raw material procurement through final packaging verification.

- Integrated logistics operations enable:

- Real-time production tracking updates

- Expedited shipping coordination

- Transparent supply chain communication

- Round-the-clock customer care team provides uninterrupted technical support and post-purchase consultation services.

The Unmatched Versatility of Mirror Acrylic Sheet

Polished acrylic panels deliver unmatched adaptability across diverse usage scenarios. Weighing nearly 50% less than conventional glass mirrors, these shatterproof alternatives prioritize user safety while simplifying installation processes – particularly crucial in high-traffic environments.

Manufacturing precision ensures uniform material density across all sheet dimensions, maintaining optical clarity from edge to edge. Custom sizing services help businesses optimize material utilization, reducing surplus stock while meeting specific project requirements. The substrate’s inherent flexibility allows straightforward modification using conventional workshop equipment, enabling intricate pattern cutting through laser technology or precision shaping via CNC machinery.

Beyond their primary reflective function, these surfaces accept various finishing techniques for personalized decorative applications. The durable backing layer preserves mirror-like luminosity while resisting environmental degradation, making them suitable for both interior design elements and exterior installations. Maintenance-friendly characteristics combined with impact resilience position these panels as cost-effective substitutes for fragile glass counterparts across multiple industries.

Acrylic mirror sheets are an excellent, less expensive alternative to glass mirrors, offering superior durability and safety. Acrylic glass sheet options are also good choice. Please note: for any specific requirements or to discuss custom sizes, please contact Sanyu Acrylic directly.

Acrylic sheets represent a substantial leap forward in materials technology. You gain the look of a traditional mirror with the increased benefits. We encourage you to explore our frosted acrylic sheet and clear acrylic sheet offerings as well. And if you have a need for something unique, be sure to check out our selection of textured Acrylic Sheet products.

Get incredibly durable, lightweight, and shatter-resistant mirror acrylic sheets at wholesale prices! Perfect for displays, signage, and construction. Customizable sizes, easy to work with, and a safer, more affordable alternative to glass. Get a crystal-clear reflection without the risk – contact us for bulk orders today!

10 things to note when purchasing products from China

Help Center

Have a query? Please check this question and answers

Yes, we use 100% premium-grade virgin acrylic (PMMA) with no recycled content, ensuring superior clarity, UV resistance, and long-term durability for all products.

We are ISO 9001 certified for quality management and comply with REACH/SGS environmental standards. Custom certifications (e.g., FDA for food-grade acrylic) can be provided upon request.

Standard items: 7-10 days. Custom orders: 12-18 days depending on complexity. Rush orders can be discussed.

Yes. We provide CNC cutting, laser engraving, thermoforming, and edge polishing. Send us CAD files/DXF designs for instant quoting. Minimum order: 10 pieces per design.

Standard thickness: 1mm-15mm. Colors: Clear, frosted, 16+ transparent colors, and custom Pantone matching (MOQ 500kg). Tolerance: ±0.2mm.

We provide 3 free A4-sized samples. Customers cover DHL/UPS shipping costs. Sample lead time: 72 hours.

Color variations in acrylic sheets can occur due to several factors, including:

Production batch differences: Slight changes in pigment concentration or raw materials between batches.

Manufacturing conditions: Variations in temperature, pressure, or curing time during production.

UV exposure: Prolonged sunlight exposure may cause fading or color shifts.

Cutting/processing: Heat generated during cutting or machining can alter surface color temporarily.

Store in a cool, dry, UV-protected environment away from direct sunlight.

Keep protective films intact until installation to avoid scratches or chemical reactions.

Avoid stacking sheets with uneven pressure, which may cause stress-induced discoloration.

While custom colors reduce risks, absolute consistency is challenging. Always request a pre-production sample and agree on a tolerance range with the supplier.