-

Xinqi Development Zone, Leliu, Foshan, Guangdong

How to Cut Acrylic Sheet?

Cut Acrylic Sheet Like a Pro

This article is your comprehensive guide to understanding and working with acrylic sheets, commonly known as plexiglass. Whether you’re a supermarket chain looking to create custom displays, a wholesaler needing bulk quantities, a building material supplier sourcing durable materials, or a decoration supplier seeking versatile options, this guide will provide valuable insights into cutting, customizing, and utilizing acrylic sheets. We’ll cover everything from choosing the right tools to achieving a perfect finish, ensuring you’re well-equipped to handle this versatile material. We, as an acrylic sheet manufacturer and wholesaler, provide useful experience about acrylic sheets.

Table of Contents

1. What is Acrylic Sheet and Why Choose It?

Acrylic sheet, often referred to as plexiglass, is a versatile thermoplastic known for its strength, clarity, and lightweight nature. It’s a popular alternative to glass due to its impact resistance – it’s up to 10 times more resistant to impact than glass [^1] – and its weatherability. Acrylic is also easy to fabricate, making it ideal for a wide range of applications.

As an acrylic sheet manufacturer, we understand the inherent benefits of this material. For supermarkets, acrylic offers a shatter-resistant solution for displays and signage. Wholesalers appreciate its durability for storage and transport. Building material and decoration suppliers value its versatility for construction and design projects. Acrylic sheet is an excellent material choice all around.

2. What are the Different Types of Acrylic Sheets Available?

Acrylic sheets come in a variety of types, each with unique properties. There’s clear acrylic sheet, colored, frosted acrylic sheet, mirrored, and textured, among others. Colored acrylic sheets offer design flexibility. Textured acrylic sheet can add a unique visual element.

Our range includes everything from standard clear sheets to specialized options. We offer wholesale acrylic sheets to meet bulk order needs and can provide custom solutions tailored to specific requirements. This flexibility makes acrylic suitable for diverse applications across industries.

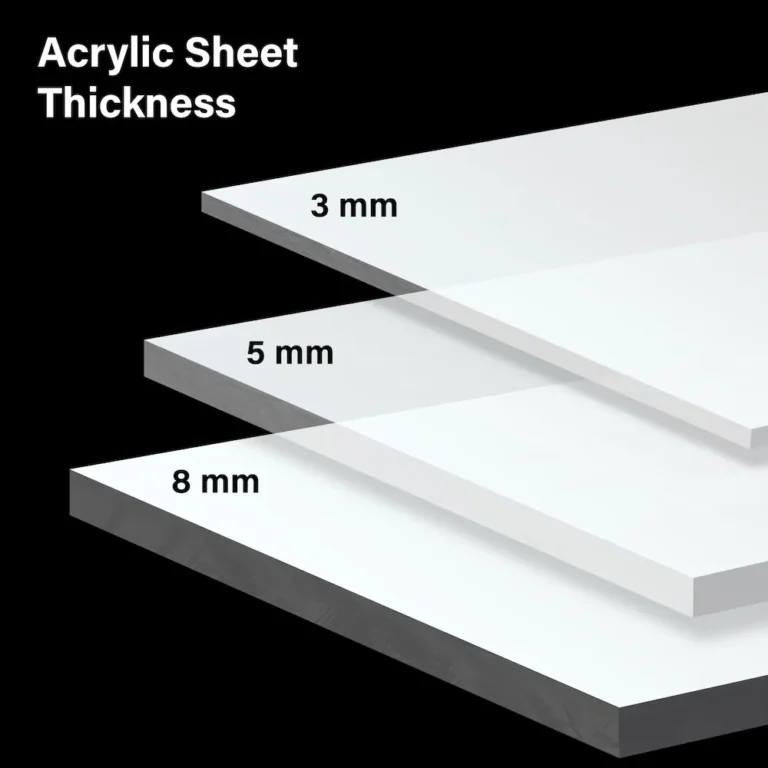

3. How to Choose the Right Thickness for Your Acrylic Sheet Project?

The thickness of the acrylic sheet you choose depends on the intended application. Thinner sheets (e.g., 2mm acrylic sheet) are suitable for smaller projects like picture frames, while thicker sheets (e.g., 5mm acrylic sheet) are better for applications requiring greater strength and rigidity, such as shelving or display cases.

Consider the load-bearing requirements and potential impact when selecting the thickness. A supermarket display, for instance, might require a thicker sheet than a decorative panel. Our team can guide you in selecting the optimal thickness for your project’s specific needs, ensuring structural integrity and performance.

4. What Tools Do You Need to Cut Acrylic Sheet?

Several tools can be used for cutting acrylic sheet. These include table saws, circular saws, scroll saws, routers, and even utility knives for scoring thinner sheets. The choice of tool depends on the thickness of the acrylic, the complexity of the cut, and the desired finish.

For straight cuts on thicker sheets, a table saw is often the best choice. For curved cuts, a scroll saw or router may be more appropriate. It’s crucial to use blades designed specifically for cutting plastic to prevent chipping and ensure a clean cut.

5. How to Cut Acrylic Sheet with a Table Saw?

Using a table saw to cut acrylic requires a specialized blade. A blade with a high teeth per inch (TPI) count, specifically designed for cutting plastic, is recommended. This helps to minimize chipping and create a smoother edge.

Here’s a step-by-step approach:

- Preparation: Ensure the acrylic sheet is held firmly against the saw’s fence. You may use clamp to secure the sheet.

- Blade Selection: Use a carbide-tipped blade designed for plastics.

- Cutting: Feed the acrylic sheet through the saw at a steady, even pace. Avoid forcing the sheet, which can cause chipping.

- Coolant: Using compressed air,or a bottle of water can act as a coolant, and it can help to prevent the acrylic from melting and sticking to the blade.

6. Can You Cut Acrylic with a Circular Saw or Scroll Saw?

Yes, both circular saws and scroll saws can be used to cut acrylic. Circular saws are best suited for straight cuts, while scroll saws allow for intricate, curved cuts. Again, the blade choice is crucial.

For a circular saw, use a blade similar to that used on a table saw – high TPI, designed for plastics. For a scroll saw, select a fine-toothed blade, and consider using a lower speed setting to prevent overheating and melting. In either case, lubrication can be beneficial.

7. Is it Possible to Cut Acrylic Sheet with a Router?

A router is an excellent tool for creating intricate shapes and decorative edges on acrylic sheet. Using a router bit designed for plastics, you can achieve smooth, professional-looking results.

When routing acrylic:

- Secure the Sheet: Clamp the acrylic firmly to a work surface or use a fixture.

- Bit Selection: Choose a carbide-tipped router bit designed for plastics.

- Routing Speed: Use a moderate speed to avoid overheating.

- Multiple Passes: For thicker sheets, make multiple shallow passes rather than trying to cut through in one go.

8. How to Achieve a Smooth, Polished Edge on Cut Acrylic?

After cutting, the edge of the acrylic sheet may be rough. To achieve a smooth, polished edge, you’ll need to sand and potentially polish the cut surface. Start with a coarser grit sandpaper (e.g., 120 grit) and gradually move to finer grits.

For a glossy, professional finish, use a polishing compound specifically designed for acrylic. This extra effort will significantly enhance the appearance of the finished product, especially for applications where the edge is visible, such as display cases or signage.

9. What Safety Precautions Should You Take When Cutting Acrylic Sheet?

Safety is paramount when working with any power tools. When cutting acrylic sheet, always wear safety glasses to protect your eyes from flying debris. Consider using a mask to avoid inhaling plastic dust.

Ensure the work area is well-ventilated. Secure the acrylic sheet properly before cutting to prevent movement and potential accidents. Never force the cutting tool; let the blade do the work.

10. How Can Our Acrylic Sheet OEM and Custom Services Benefit You?

As an acrylic sheet manufacturer and wholesaler, we offer more than just standard sheets. We provide OEM and custom services to meet your unique needs. This includes custom sizes, colors, textures, and even pre-cut shapes, saving you time and resources. This capability is particularly beneficial for projects with specific design requirements.

Our manufacturing plants are equipped to handle large-scale orders, ensuring timely delivery for wholesalers and large projects. Whether you need a specific thickness, a unique color, or a complex shape, we can fabricate acrylic sheet to your exact specifications. Our acrylic glass sheet offers exceptional clarity. Mirror Acrylic Sheet adds a reflective.

FAQs

Can acrylic be welded?

Yes, acrylic can be chemically welded using specialized solvents. This creates a strong, nearly invisible bond.

What is the best way to clean acrylic sheet?

Use a soft cloth and a mild soap and water solution. Avoid abrasive cleaners or solvents, which can damage the surface.

How does acrylic compare to polycarbonate?

While both are strong plastics, polycarbonate is even more impact-resistant than acrylic. However, acrylic has better clarity and is less prone to scratching.

Can acrylic be used outdoors?

Yes, acrylic is weather-resistant and can withstand prolonged exposure to sunlight and the elements.

What is the tolerance for cut acrylic sheet?

The cutting tolerance will vary but will typically be in the range of +/- .01mm. However, please get in touch with us and discuss your tolerance needs.

How can I prevent scratching during fabrication?

Keep the protective mask on the acrylic sheet for as long as possible during fabrication.

Summary

- Acrylic sheet is a versatile material suitable for various applications.

- Different types and thicknesses of acrylic sheets are available for different project needs.

- Proper tools and techniques are essential for cutting acrylic cleanly and safely.

- Sanding and polishing can create a smooth, professional finish.

- Safety precautions should always be followed when working with acrylic and power tools.

- OEM and custom services provide tailored solutions for specific project requirements.

- As a manufacturer, we provide high-quality materials.

We encourage you to contact us to discuss your specific acrylic sheet needs. Our expertise and capabilities can help you achieve your project goals efficiently and effectively.