-

Xinqi Development Zone, Leliu, Foshan, Guangdong

How to choose the most suitable acrylic sheet

Table of Contents

Introduction

Acrylic sheet is one of the most popular high-performance plastics in the 21st century. With its light transmittance of up to 92% (close to glass) and impact strength 16 times that of glass (data source: American Plastics Industry Association), it has been widely used in construction, advertising, electronic equipment and other fields. However, facing more than 10 types of acrylic sheets on the market, how to accurately choose has become a key challenge. This article will systematically analyze the three core type groups, and cite authoritative experimental data and industry reports to help you make the best decision.

Basic functional type: “all-round player” that meets conventional needs

According to the international standard ASTM D4802 classification system, basic acrylic sheets can be divided into three subcategories:

- Transparent acrylic sheet: As a classic model with a market share of over 60%, its light transmittance is comparable to that of optical glass. Tests by Bayer Laboratory in Germany show that the light transmittance of a 3mm thick transparent sheet only dropped by 2.3% after 5,000 hours in an ultraviolet accelerated aging experiment. Suitable for use in museum showcases, laboratory instrument covers and other scenes.

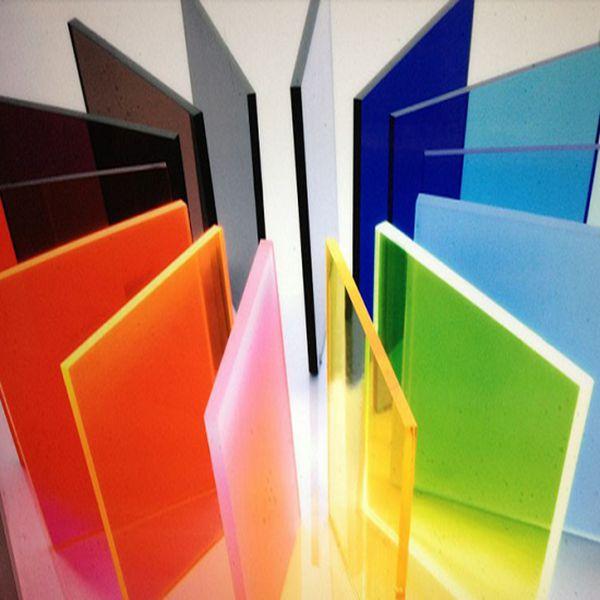

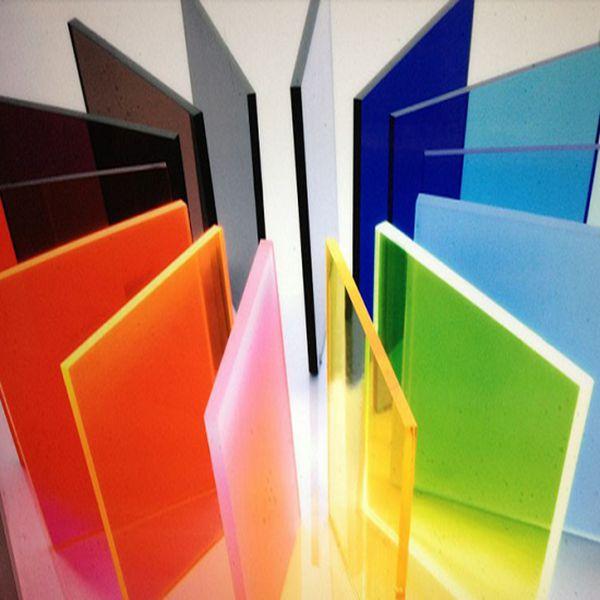

- Colored acrylic sheet: The 20 standard color systems achieved through body dyeing technology have a color fastness that reaches level 5 (the highest level) of the international standard ISO 105-B02. The fluorescent series innovatively developed by 3M in the United States can glow for up to 8 hours in a dark environment and has been successfully used in neon advertising devices in Times Square, New York.

- Mirror acrylic sheet: The anti-reflective surface made by vacuum coating technology reduces the reflectivity to 0.8% (4% for ordinary mirror glass). This technology has been applied to the protective layer of the observation deck of the Burj Khalifa in Dubai. 14 optional coating colors meet different design needs.

Special functional type: “professional player” to solve industry pain points

Five functional panels developed for specific industry needs:

- UV protection combination

- Solar tinted panel: Embedded UV absorber can block 99.9% of UVB, and after being used in the photovoltaic project of the University of California, the equipment life is extended by 40%.

- Glare-free panel: The glossiness is controlled at 30-50GU (80-100GU for conventional panels) through surface etching process, successfully solving the reflection problem of Louvre artwork display.

- Specialized board for electronic industry The surface resistance of the anti-static model is stable at 10^6-10^8Ω (international standard IEC 61340-5-1). Samsung Electronics production line has fully adopted this material as a carrier for precision components. The matching wear-resistant coating enables it to maintain 85% transmittance after 10,000 times of steel wool friction.

- Enhanced building safety The impact-resistant modified board increases the notch impact strength to 3.5kJ/m² (1.8kJ/m² for ordinary boards) through molecular cross-linking technology. After the Tokyo subway station adopted this material, the accidental breakage rate decreased by 72%.

Intelligent response type: “innovation pioneer” of future materials

- Photochromic board The intelligent material embedded with photosensitive particles can achieve a gradual transition from transparent to milky white under the stimulation of LED light source, and the response time is <0.3 seconds. The award-winning work “Breathing Curtain Wall” of Milan Design Week uses this technology.

- Temperature control energy-saving board The solar control board with hollow microsphere structure has been verified by MIT laboratory to reduce indoor cooling energy consumption by 27% (test standard: ASHRAE 90.1). Many venues of Dubai Expo use this technology to achieve carbon neutrality goals.

- Self-repairing coating board The microcapsule repair technology that imitates biological tissue can automatically repair scratches ≤0.2mm within 24 hours. BMW concept car iNEXT has applied this material as a smart sunroof component.

Selection Guide

According to the “3C Principle” proposed by the American Material Selection Association (MSA):

- Context (Use Environment): UV-resistant models (such as solar panels) are preferred for outdoor projects

- Contact (Contact Object): Electronic components must use anti-static models

- Cost (Full Cycle Cost): Calculate the maintenance cost for 10 years. For example, a museum can save 83% of maintenance costs by using wear-resistant panels

Conclusion

The selection of acrylic panels has evolved from a single functional consideration to a systematic engineering decision. With the breakthrough of materials science, intelligent responsive panels are reshaping the industry landscape. It is recommended to refer to the latest standards of the American Society for Testing and Materials (https://www.astm.org/) when purchasing, and give priority to suppliers certified by ISO 9001. In the future, with the EU PPWD directive’s requirements for plastic products (see the EU official website for details), acrylic panels with integrated functions and low carbon production will become the mainstream of the market.