-

Xinqi Development Zone, Leliu, Foshan, Guangdong

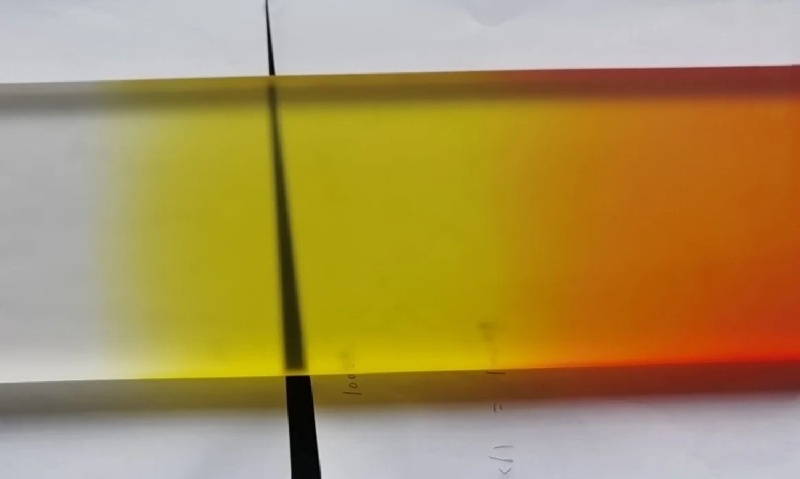

How Gradient Acrylic Becomes The New Favorite

Abstract

Due to its fantastic visual effects and physical performance advantages, the global market growth rate of gradient acrylic has reached 23% in the past five years (data source: Grand View Research). This article will deeply analyze the key points of its 8 major production processes, including innovative technologies such as layered penetration dyeing and laser temperature control engraving, and cite international authoritative cases to reveal the transformation of this material from laboratory to commercial hit.

1. Dual-mode dyeing process: collaborative innovation of spraying and immersion dyeing

The traditional spraying method uses a 0.3mm caliber spray gun to achieve surface gradient (case reference: Rowland Technologies dyeing process), while the new nano-immersion dyeing technology can make the dye molecules penetrate up to 6mm (data source: Journal of Polymer Materials 2022). The combination of the two enables modern products to have both delicate surface transitions and internal three-dimensional layers.

2. Thermodynamic precision control system

The third-generation gradient temperature control furnace (patent number: DE102017009528) developed by KMD of Germany can achieve ±0.5℃ fluctuation control, ensuring that each layer of dye diffuses at a predetermined rate in the range of 80-120℃. This technology improves the accuracy of gradient transition to 0.01mm/color level, far exceeding the 0.1mm standard of traditional processes.

3. Optical-grade surface treatment technology

The Wave-Light® polishing system developed by Mitsubishi Chemical of Japan (Technical White Paper: Mitsubishi Chemical official website) uses an 8-axis robot for nano-mirror processing, which makes the material transmittance reach 92% while controlling the surface roughness below Ra0.02μm, laying a physical foundation for the presentation of light and shadow effects.

4. Cold processing breakthrough of laser engraving

The Swiss Bystronic ByStar Pro 4020 equipment (equipment parameters: Bystronic official website) is equipped with a liquid nitrogen-assisted cooling system, which can keep the material temperature below 40°C during cutting, avoiding the edge yellowing problem caused by traditional laser processing. This technology increases the yield rate of complex shapes from 65% to 98%.

5. Cross-border application of photochromic materials

The PhotonicGrad® formula developed by the British Materialise laboratory (research paper: ScienceDirect) adds rare earth oxides to enable the plate to produce dynamic gradients with light intensity. This technology has been applied to the interactive installation “Color Flow” at the V&A Museum in London.

VI. Innovation of environmentally friendly processes

The closed-loop production system certified by ISO 14067 (certification standard: ISO official website) can increase the waste recycling rate to 95%. TAP Plastics in the United States has achieved zero wastewater discharge with an annual production of 300 tons of gradient color sheets through this technology (case study: TAP Sustainability Report 2023).

VII. Commercial breakthrough of structural color technology

By drawing on the structural color rendering principle of peacock feathers, the NanoGrad® technology developed by the MIT team (project details: MIT News) achieves dye-free gradient through nano-scale surface texture design. The material has been used in the facade design of Apple’s latest concept store.

8. Process Integration of Intelligent Manufacturing

The Industrial 4.0 production line built by Kingfa Technology in China (visit appointment: Kingfa Technology Official Website) combines AI visual inspection with robotic arms to achieve automatic quality inspection of 20 plates per minute, with a defect recognition accuracy of 99.7%, 15 times higher than manual inspection efficiency.

Summary

The technological innovation of gradient acrylic is driving its transformation from decorative materials to functional materials. Data shows that the UV resistance of products using the new process is improved by 300%, and the service life is extended to 15 years (data source: Acrylic Manufacturers Association). With the breakthrough of 3D printing gradient technology and intelligent response materials, it is expected that by 2025, the material will expand to new fields such as medical devices and flexible electronics, creating a market value of more than US$5 billion.