-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Glossy vs Frosted vs Mirror Acrylic Sheets Price Difference

Table of Contents

Introduction

In the fields of advertising signs, interior decoration and industrial design, acrylic sheets occupy an important position with their excellent light transmittance and plasticity. According to Grand View Research data, the global acrylic sheet market size will exceed US$6 billion in 2023, and the surface treatment process has become a key variable affecting product prices. This article compares the cost structure of the three mainstream processes of glossy, frosted and mirrored, and combines authoritative industry data to reveal the core logic behind the price difference and provide scientific material selection suggestions.

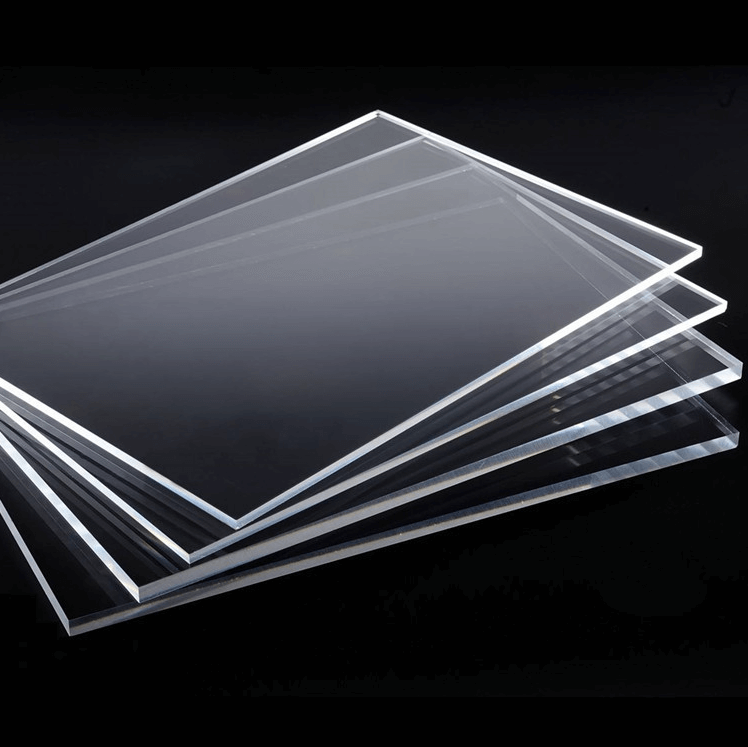

Basic process cost: glossy acrylic has the most cost-effective advantage

As a basic product, the price baseline of glossy acrylic sheets is stable at $2-$5/square foot . This standard process using hot pressing molding controls the production loss rate within 5% and does not require additional surface treatment processes. In contrast, the frosting process requires the addition of sandblasting or chemical etching processes, which increases the cost by about 30%-50%; the mirror process involves vacuum coating technology, and the equipment investment is as high as 3 times that of ordinary production lines, which directly causes the unit price to jump to $8-$15/square foot.

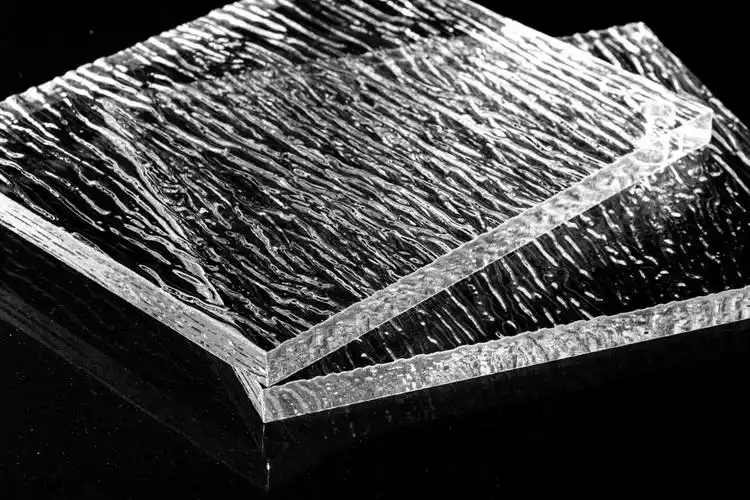

Functional premium: anti-glare properties push up the value of frosted boards

The American Society for Testing and Materials (ASTM) research shows that frosted acrylic boards that have been atomized can increase the diffuse reflectivity of light to 85%, which has led to a continuous increase in its application rate in high-end commercial spaces. Taking 3mm thick boards as an example, the retail price of ordinary light panels is $18/㎡, while the price of frosted boards of the same specifications is $25/㎡ (data source: TAP Plastics). This 20%-40% premium mainly comes from:

① The independent operation and maintenance cost of the sandblasting workshop

② The investment in surface uniformity detection equipment

③ The scrap rate is 3-5 percentage points higher than that of light panels.

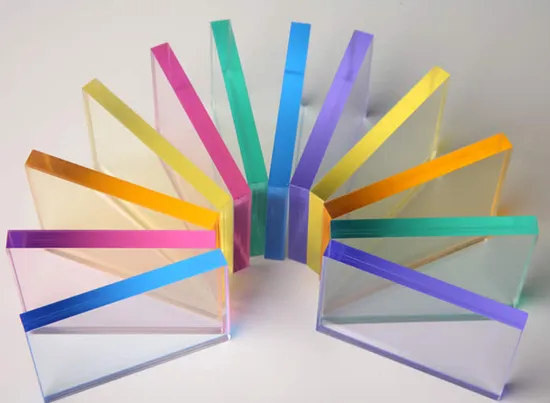

Decorative premium: Mirror technology creates the highest added value

Mirror acrylic has created an amazing premium in the field of luxury display cabinets with a mirror reflectivity of more than 92% (close to 95% of ordinary glass mirrors). The test report of German material supplier Röhm pointed out that its mirror film layer process includes 7 nano-level coatings, making the unit price of the product 3-5 times that of ordinary glossy panels. This process difference is obvious in the terminal market: IKEA’s standard glossy shelf is priced at $12.99, while the mirror version is priced at $39.99.

Customization cost gradient: special needs exacerbate price differences

By comparing the quotations of 100 suppliers on Alibaba platform, it is found that the price difference of standard specification products is about 1.8 times, but when it comes to the following customized needs, the price difference can be expanded to more than 5 times:

- Special-shaped cutting (+15%-30%)

- Thickness exceeding 10mm (cost +8% for each additional 1mm)

- Anti-UV coating (+$2.5/㎡)

- Fire rating certification (+20%-50%)

- Small batch customization (+30% when the minimum order quantity is less than 50㎡)

Full life cycle cost: hidden value affects the real cost performance

A comparative study by the U.S. Green Building Council (USGBC) shows that although mirror acrylic has the highest initial cost, its 15-year weather resistance (compared to 8-10 years for light panels) can reduce maintenance costs by 50%. This long-term value is particularly evident in building curtain wall projects: the 10-year comprehensive cost of projects using mirror technology is $150/㎡, while the frequently replaced light panel solution is $210/㎡.

Other price influencing factors

- Difference in raw material purity: The price of medical-grade PMMA particles is 40% higher than that of industrial-grade

- Regional transportation costs: The landed price of light panels in East China is 8%-12% higher than that in South China

- Environmental certification premium: The price of products that have passed REACH certification is 15% higher

FAQs of the Price Difference

Which is the cheapest among glossy, frosted and mirrored acrylic sheets?

Glossy acrylic sheets are the cheapest, about 2 − 2−5/square foot; frosted sheets are 30%-50% more expensive, and mirrored sheets can be 3-5 times more expensive than glossy sheets.

Why are mirrored acrylic sheets the most expensive?

Because it requires vacuum coating technology, the equipment cost is high and the scrap rate increases, and the reflectivity is more than 92%

Is it reasonable to only look at the unit price when purchasing?

Not recommended. The full life cycle cost needs to be considered. The durability of the mirrored sheet is 15 years, and the maintenance cost is 50% lower than that of the glossy sheet

How to avoid buying inferior acrylic sheets?

Look for UL certification and REACH environmental protection logo, and require a light transmittance test report

Conclusion

The price difference of acrylic board surface treatment technology is essentially a comprehensive reflection of functional value and process cost. From an economic perspective, light panels are still the first choice for cost-effectiveness in the mass market; when pursuing specific functions, the 20%-40% premium of frosted panels can obtain practical value such as anti-glare; and the 3-5 times price difference of mirror panels corresponds to its decorative premium and long-term durability. It is recommended that buyers refer to the “Acrylic Product Selection Guide” issued by the American Plastics Industry Association (SPI), conduct full cost accounting in combination with the project budget cycle (3 years/5 years/10 years), and pay special attention to quality documents such as UL certification and transmittance test reports to avoid low price traps.