-

Xinqi Development Zone, Leliu, Foshan, Guangdong

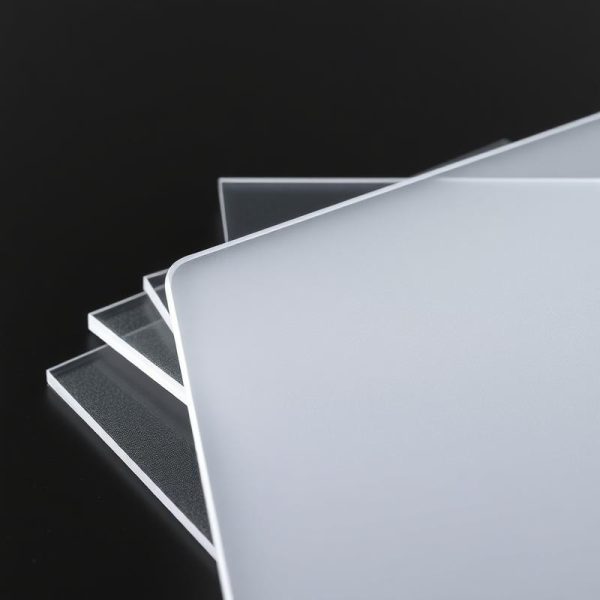

3mm Frosted Cutting Acrylic Glass Sheet

Frosted acrylic sheets combine elegance and functionality, offering a lightweight, versatile, and impact-resistant alternative to traditional glass.As a trusted producer in the sheet materials industry, we deliver durable surface solutions designed for bulk purchasing needs and collaborative wholesale ventures. Our engineered polymer panels provide 5-21x greater resilience than conventional glass while maintaining remarkable lightness, making them particularly suitable for high-traffic retail environments and construction material procurement centers. Customizable sizing options ensure cost-efficient implementation for large-scale commercial applications, offering buyers substantial savings compared to fragile glass alternatives without compromising professional-grade performance standards.

Why Choose Us?

- Bulk Pricing: Competitive rates for large orders.

- Fast Delivery: 5-7 working days

- Quality Assurance: Uniform frosted finish with no significant loss of frosted appearance over time.

Technical Specifications:

- Thickness: Our standard size is 3mm, but we also offer options from 1mm to 20mm thickness.

- Sheet Sizes: 1250x2500mm is the standard size, width of 900-2050 is available, length is up to our clients and custom dimensions with ±0.5mm tolerance.

- Finishes: Matte white, textured, or smooth frosted plexiglass.

Our cut-to-size service eliminates waste, allowing you to order exact dimensions for projects like:

- Retail displays

- Office partitions

- Gift packaging inserts

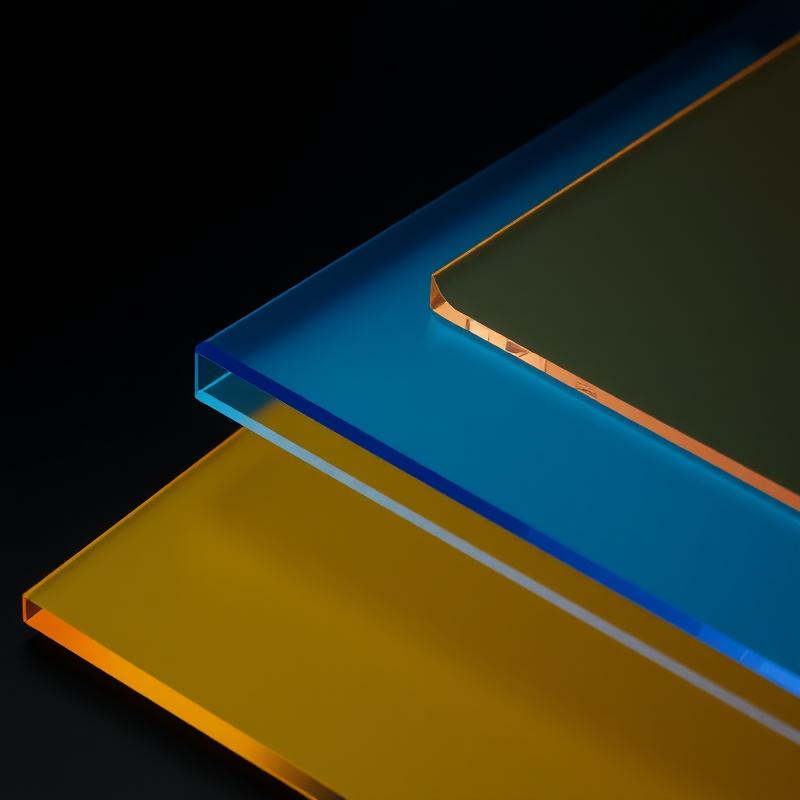

For more options, check our colored acrylic sheets which are available in different colors like gold, red, blue, purple, black and translucent white.

Why Choose Frosted Acrylic Sheets Over Traditional Glass?

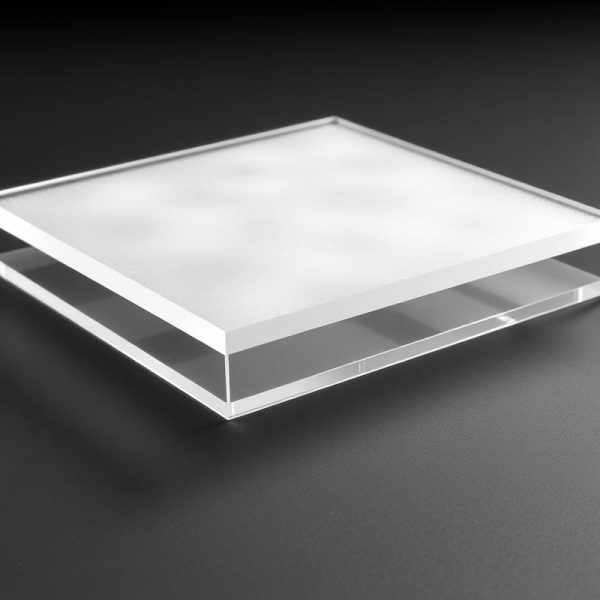

Frosted acrylic sheets makes industries as a lightweight, shatterproof alternative to glass. They combine reduced weight with exceptional durability – weighing half as much as glass while offering 10x greater resistance to impacts. This makes the frosted acrylic sheets particularly valuable for commercial settings requiring frequent modifications, such as store displays or workplace dividers.

This combination of practical benefits proves particularly useful in dynamic environments. Businesses requiring adaptable setups – from rotating retail displays to reconfigurable office partitions – benefit from acrylic’s dual advantages. The material’s lighter weight simplifies installation and transportation, while its break-resistant nature reduces maintenance costs and safety risks in high-traffic areas.

Key Benefits:

- Enhanced Safety Profile: The non-splintering nature eliminates injury risks from broken edges, crucial for high-visibility installations like museum exhibits or transportation hubs.

- Optimized Light Distribution: Engineered surface texture creates uniform illumination perfect for architectural lighting features or premium-branded signage requiring consistent visual appeal.

- Weather Resilience: Advanced UV inhibitors protect against yellowing and surface degradation, ensuring long-term performance for outdoor applications from building facades to patio screens.

| Property | Frosted Acrylic | Glass |

|---|---|---|

| Weight (per sq. ft) | 1.2 lbs | 6.5 lbs |

| Impact Resistance | 5-21x higher | Low |

| Thickness Options | 1mm–20mm | Limited |

For projects requiring privacy without sacrificing light transmission, explore our translucent white acrylic sheet, perfect for modern interiors.

Customizable Sizes and Finishes for Every Project

Whether you need 48 x 96 acrylic sheets for large signage or custom-cut panels for unique displays, our manufacturing capabilities ensure precision and consistency.

Durable and Versatile Applications Across Industries

Frosted acrylic’s versatile nature makes it a top choice for diverse sectors.

Industry-Specific Uses:

- Building Material Markets: Lightweight panels for skylights or surface covers.

- Gift Wholesalers: Laser-engraved promotional items using 2-tone acrylic sheets.

- Supermarkets: Hygienic, easy-to-clean display cases.

Environmental Impact:

- Recyclable: 100% reusable material.

- Energy Efficient: Lower production carbon footprint vs. glass.

Why Partner With Us?

- Bulk Discounts: Save up to 30% on 100+ sheet orders.

- Fast Turnaround: 5–7 business days for custom sizes.

- Technical Support: Expert guidance on fabrication and light diffusion techniques.

Ready to elevate your projects? Contact us today for a quote on frosted acrylic sheets or explore our acrylic mirror sheets for reflective applications.

10 things to note when purchasing products from China

Help Center

Have a query? Please check this question and answers

Yes, we use 100% premium-grade virgin acrylic (PMMA) with no recycled content, ensuring superior clarity, UV resistance, and long-term durability for all products.

We are ISO 9001 certified for quality management and comply with REACH/SGS environmental standards. Custom certifications (e.g., FDA for food-grade acrylic) can be provided upon request.

Standard items: 7-10 days. Custom orders: 12-18 days depending on complexity. Rush orders can be discussed.

Yes. We provide CNC cutting, laser engraving, thermoforming, and edge polishing. Send us CAD files/DXF designs for instant quoting. Minimum order: 10 pieces per design.

Standard thickness: 1mm-15mm. Colors: Clear, frosted, 16+ transparent colors, and custom Pantone matching (MOQ 500kg). Tolerance: ±0.2mm.

We provide 3 free A4-sized samples. Customers cover DHL/UPS shipping costs. Sample lead time: 72 hours.

Color variations in acrylic sheets can occur due to several factors, including:

Production batch differences: Slight changes in pigment concentration or raw materials between batches.

Manufacturing conditions: Variations in temperature, pressure, or curing time during production.

UV exposure: Prolonged sunlight exposure may cause fading or color shifts.

Cutting/processing: Heat generated during cutting or machining can alter surface color temporarily.

Store in a cool, dry, UV-protected environment away from direct sunlight.

Keep protective films intact until installation to avoid scratches or chemical reactions.

Avoid stacking sheets with uneven pressure, which may cause stress-induced discoloration.

While custom colors reduce risks, absolute consistency is challenging. Always request a pre-production sample and agree on a tolerance range with the supplier.