-

Zone de développement de Xinqi, Leliu, Foshan, Guangdong

Comment peindre ou imprimer sur des feuilles acryliques pour les marques

La réalisation d'une expression de marque précise et durable sur la surface des matériaux est devenue le champ de bataille central de la compétition visuelle des entreprises modernes.

Les feuilles acryliques sont devenues le matériau de choix pour la signalétique d'entreprise, les dispositifs d'affichage et les décorations haut de gamme en raison de leur haute transparence, de leur haute résistance, de leur légèreté et de leur résistance aux intempéries.

Ce matériau polyvalent remplace non seulement le verre traditionnel, mais permet également une personnalisation approfondie grâce à la technologie de peinture et d'impression, offrant aux entreprises une gamme complète de solutions, des logos de marque aux présentations artistiques.

Poussée par l'innovation continue dans les processus de traitement de surface, la technologie de personnalisation acrylique brise les limitations traditionnelles d'adhérence et de durabilité, ouvrant de nouvelles possibilités pour les applications commerciales.

Technologie de base de la peinture : traitement de surface et sélection du processus

La peinture feuilles acryliques est bien plus qu'un simple revêtement : c'est une combinaison sophistiquée de science des matériaux et de technologie de processus. Les entreprises doivent sélectionner des revêtements conçus pour les plastiques, tels que la peinture acrylique ou la peinture en aérosol spécifique au plastique, afin de garantir la compatibilité entre le revêtement et le substrat.

Le prétraitement de surface détermine directement le succès ou l'échec de la peinture : utilisez d'abord un détergent doux pour éliminer l'huile et la poussière, puis utilisez du papier de verre fin 800-1200 pour polir doucement la surface afin de former une micro-texture, ce qui améliore considérablement l'adhérence du revêtement. Cette étape clé évite le risque de décollement ou de fissuration du film de peinture.

Le processus de peinture doit être sélectionné avec souplesse en fonction des exigences du projet :

- Pinceau à main: Contrôler précisément les petites zones, adapté aux motifs complexes ou à la retouche de peinture

- Pistolet de pulvérisation spécial: Obtenir une couverture uniforme des grandes surfaces, améliorer considérablement l'efficacité

- Revêtement de durcissement UV: En tant que couche protectrice finale, améliorer la résistance aux intempéries extérieures

Sérigraphie et impression UV : analyse approfondie des deux principaux processus

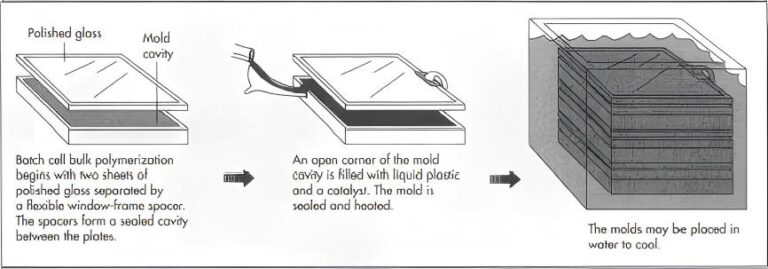

Il existe deux grandes voies techniques dans le domaine de l'impression acrylique, chacune étant adaptée à différents scénarios commerciaux :

La sérigraphie présente un avantage dans les tâches monochromes en petits lots en raison de son économie. Le cœur de son processus consiste à transférer l'encre sur la surface acrylique par pression d'écran, et le coût initial de fabrication de la plaque est d'environ 200 à 300 yuans.

Cette technologie est particulièrement adaptée à la production en série de logos d'entreprise fixes : une fois l'écran fabriqué, il peut être réutilisé pour réduire considérablement le coût par pièce. Cependant, son goulot d'étranglement technique est évident : une seule couleur peut être imprimée à la fois, et l'effet de dégradé ne peut pas être obtenu. De plus, plusieurs fabrications de plaques sont nécessaires pour la surimpression multicolore, et le coût augmente fortement.

L'impression à plat UV représente l'avant-garde technologique de l'impression numérique. L'équipement adopte la technologie d'impression en niveaux de gris 8 de Japan Toshiba, avec une précision de 1440 DPI, comparable à la qualité photo. Sa percée révolutionnaire est la suivante :

- Sortie directe via des fichiers numériques, éliminant ainsi le processus de fabrication de plaques

- Impression couleur dégradée complète en une seule fois

- L'encre UV est instantanément durcie, et la résistance aux intempéries extérieures est de 3 à 5 ans

- Peut produire un toucher en relief et améliorer la dimension de l'affichage de la marque

Cette technologie nécessite l'application d'un revêtement spécial avant l'impression pour résoudre le problème d'adhérence et garantir la stabilité durable de l'image sur la surface acrylique lisse

Percée technologique : surmonter le problème de transparence du fond du revêtement blanc dans l'industrie

La production acrylique transparente de revêtement blanc pur est depuis longtemps confrontée au problème de la transparence du fond : dans le cadre des processus traditionnels, les marques de colle à l'arrière et la structure interne de l'équipement sont vaguement visibles, ce qui affecte sérieusement l'effet d'affichage haut de gamme. Les solutions conventionnelles d'autocollants de voiture blancs sont sujettes à la séparation ou au déplacement de la coque lorsque la température change, et le risque de fissuration par oxydation est plus élevé.

L'innovation technologique de Tianmei Acrylic a brisé cette impasse. Son développement processus de blanc chaud de sérigraphie est réalisé grâce à une formule d'encre spéciale :

- La couche d'encre est pleine et épaisse, recouvrant complètement le substrat

- Le bord est lisse et ne tombe pas après la découpe CNC

- Résistant à l'essuyage à l'alcool et à la corrosion chimique

- Vérification de la stabilité environnementale de -40 ℃ à 80 ℃

Cette technologie est particulièrement adaptée aux vitrines haut de gamme, aux espaces de vente au détail de luxe et aux stands de musée. Après l'installation, les défauts du panneau arrière sont complètement isolés, présentant une expérience visuelle pure. Dès lors, l'entreprise s'est débarrassée de la perte due aux défauts causés par la transparence du fond et a amélioré la capacité de prime du produit.

Analyse de l'ensemble du processus d'impression jet d'encre UV professionnelle

La mise en œuvre d'une impression jet d'encre UV acrylique de haute qualité nécessite un flux de travail précis :

- Prétraitement du substrat: Utilisez un nettoyant non statique pour traiter la planche et positionnez la marque pour garantir la précision de l'impression

- Pulvérisation de revêtement: Améliorer l'adhérence de l'encre UV et éviter les rayures ultérieures

- Optimisation des paramètres de l'équipement: Ajustez la hauteur de la buse en fonction de l'épaisseur de la planche (généralement de 1,5 à 2 mm de la surface)

- Étalonnage du système de gestion des couleurs: Faites correspondre les numéros de couleur Pantone pour obtenir une restauration précise des couleurs de la marque

- Impression en couches et durcissement instantané: Les lampes UV sont divisées en trois niveaux d'intensité pour contrôler la réaction de polymérisation de la couche d'encre

- Couverture de couche transparente résistante à l'usure: L'impression de vernis en option augmente la dureté et la brillance de la surface

Ce processus peut atteindre un débit élevé de 84 mètres carrés par heure dans un environnement d'usine professionnel, et prend en charge les opérations grand format de 1,8 × 3,2 mètres, ce qui améliore considérablement l'efficacité de la livraison des commandes groupées des entreprises.

Scénarios d'application d'entreprise et création de valeur

Les entreprises leaders dans différents secteurs réalisent une valeur ajoutée de la marque grâce à la technologie de personnalisation acrylique :

- Commerce de détail: Boîtes de rangement de cosmétiques en acrylique personnalisées et vitrines de bijoux, logo de dégradé d'impression UV pour améliorer le taux de conversion des comptoirs

- Décoration architecturale: Le mur-rideau en croûte UV résistant au vent résiste à des vents forts de niveau 12, et le motif peint par pulvérisation ne se décolore pas pendant dix ans

- Présentation d'exposition: Acrylique dépoli combiné à l'impression en relief UV pour créer un système de guidage tactile

- Espace de bureau: Solution de mur de culture d'entreprise sérigraphiée, coût du slogan monochrome réduit de 40 %

- Publicité extérieure: La sortie UV à trois couches de protection (fond blanc + image couleur + vernis) garantit 5 ans sans entretien

Ces applications vérifient l'effet multiplicateur des solutions acryliques personnalisées sur la construction de l'image de marque de l'entreprise et l'amélioration de la valeur de l'espace.

Traitement de surface et technologie d'entretien à long terme

Le maintien de la durée de vie esthétique des produits acryliques peints/imprimés nécessite un entretien scientifique :

La technologie de renforcement chimique forme une couche protectrice composite en appliquant une couche de finition en polyuréthane aliphatique acrylique (épaisseur de 20 à 60 μm) après la pulvérisation. Il a été vérifié expérimentalement que le revêtement possède :

-Résistant à la dégradation par la lumière ultraviolette

-Résistant à la fissuration fragile à basses températures de -30 ℃

Résistant à la corrosion par le brouillard salin (convient aux entités commerciales en bord de mer)

- Le taux de rétention de la brillance sur cinq ans dépasse 90 %

L'entretien quotidien adopte une méthode de nettoyage en trois étapes:

- Dépoussiérage en microfibre pour éliminer la poussière flottante

- Essuyer avec une solution de détergent neutre (pH 6,5-7,5)

- Entretien trimestriel de l'agent de nano-revêtement pour améliorer l'hydrophobicité

Il est strictement interdit d'utiliser des produits de nettoyage contenant de l'ammoniac ou des abrasifs pour éviter le vieillissement accéléré de la surface. Dans le cadre d'un entretien professionnel, la durée de vie de l'affichage intérieur peut atteindre plus de 10 ans.

Le développement révolutionnaire de la technologie d'impression sur panneaux acryliques remodèle les limites de l'affichage commercial. De la solution monochrome économique de la sérigraphie à la sortie de dégradé couleur de l'impression jet d'encre UV, en passant par le processus de peinture blanche révolutionnaire de Tianmei Acrylic, les entreprises disposent désormais d'outils d'expression de marque sans précédent.

Lorsque ces technologies sont combinées à des solutions scientifiques de traitement de surface et d'entretien, les produits acryliques personnalisés peuvent conserver leur intégrité visuelle pendant plus de 10 ans dans des environnements difficiles.

Les entreprises qui maîtrisent ces technologies innovantes se forgent une compétitivité visuelle inégalée dans les espaces de vente au détail, les environnements d'entreprise et l'art public.