-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Benutzerdefinierte Größe große farbige Acrylglas-Platten

🕢 [ Füllen Sie das Formular aus und wir werden innerhalb von 30 Minuten antworten!]

Als führender Hersteller von Acrylglasplatten haben wir uns auf die Lieferung hochwertiger Acryl Materialien, die genau auf die Spezifikationen Ihres Projekts zugeschnitten sind. Ganz gleich, ob Sie ein Großhändler sind, der einen zuverlässigen Bestand sucht, eine Supermarktkette, die Displays plant, ein Großprojektmanager, der den Bau oder die Installation überwacht, ein Manager für Haushaltsprodukte, der neue Produktlinien entwickelt, ein Dekorationsmanager, der einzigartige Materialien beschafft, ein Werbemanager, der eine eindrucksvolle Beschilderung entwirft, oder ein Heimwerker, der spezifische Abmessungen benötigt - wir sind Ihr zuverlässiger Partner. Wir bieten maßgefertigtes Plexiglas und Acrylglasplatten direkt von der Quelle an und gewährleisten so Qualitätskontrolle und Kosteneffizienz. Wenn Sie bei uns bestellen, haben Sie Zugang zu industriellen Kapazitäten, gleichbleibender Produktqualität, einer großen Auswahl an Optionen und dem Fachwissen eines engagierten Herstellers von Acrylglasplatten. Wir rationalisieren die Lieferkette und bieten Acrylglasplatten in großen Mengen sowie Großhandelspreise für Acrylglasplatten, die auf die Bedürfnisse von Unternehmen zugeschnitten sind. Bitte beachten Sie, dass wir uns auf B2B- und Großbestellungen spezialisiert haben und keine Einkäufe im Einzelhandel ermöglichen. Als Partner bieten wir Ihnen einen unvergleichlichen Service und hochwertige Acrylglasprodukte.

Wenn Sie Ihre Acrylglasplatten direkt von unserem Werk beziehen, haben Sie folgende Vorteile:

- Kosteneinsparungen: Durch den Direkteinkauf entfallen die Aufschläge der Zwischenhändler.

- Qualitätssicherung: Strenge Qualitätskontrolle vom Rohmaterial bis zur fertigen Kunststoffplatte.

- Anpassungen: Präziser Zuschnitt von Acrylglas, einschließlich komplexer kundenspezifischer Formen und Lasercut-Fertigstellung.

- Verlässlichkeit: Konsistente Lieferkette für große Auftragsvolumen.

- Fachwissen: Jahrzehntelange Erfahrung in der Herstellung gewährleistet eine optimale Materialauswahl und Verarbeitungsberatung.

Acrylglasplatten-Typen verstehen: Gegossene vs. extrudierte Acrylglasplatten und Dickenoptionen

Die Wahl des richtigen Acryltyps ist entscheidend für den Erfolg eines Projekts. Wir fertigen und liefern sowohl gegossene als auch extrudierte Acrylglasplatten, die jeweils unterschiedliche Vorteile bieten. Gegossene Acrylglasplatten sind bekannt für ihre überlegene optische Klarheit, ihre größere Oberflächenhärte und ihre größere Auswahl an verfügbaren Dicken. Sie werden häufig für hochwertige Anwendungen wie Museumsausstellungen, hochwertige Beschilderungen und den Bau von Aquarien verwendet. Gegossenes Acryl wird hergestellt, indem flüssiges Acryl zwischen zwei Glasplatten gegossen wird, was zu einem gleichmäßigeren Molekulargewicht und weniger inneren Spannungen führt.

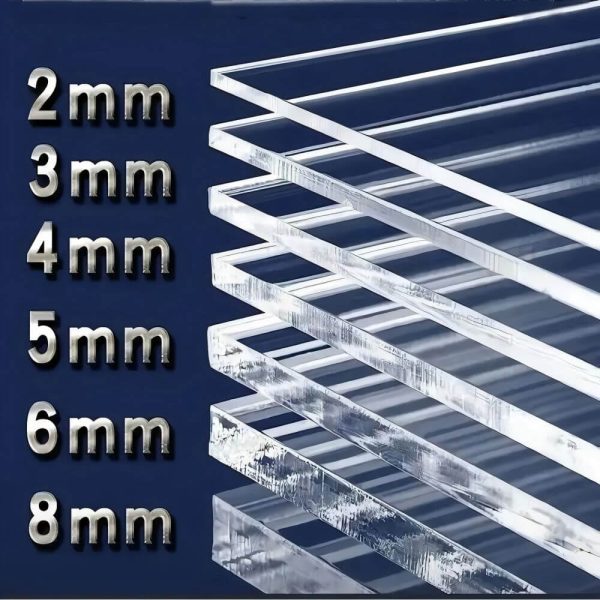

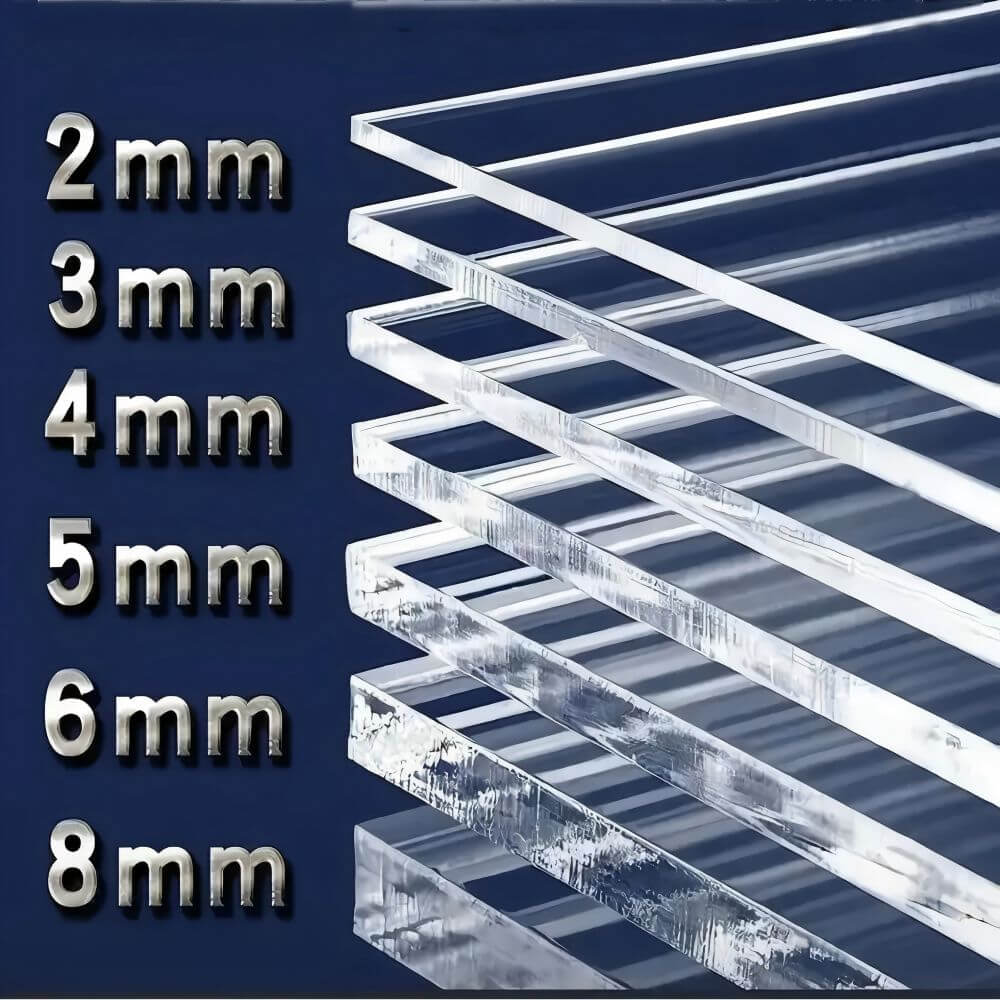

Extrudiertes Acrylwird hingegen durch das Pressen von geschmolzenen Acryl durch eine Düse, was zu einer wirtschaftlicheren Kunststoffplatte mit engerer Dickentoleranz führt. Extrudierte Acrylplatten sind zwar etwas weniger stoßfest als gegossenes Acryl, lassen sich aber leichter thermisch verformen und verkleben, so dass sie für eine Vielzahl von Anwendungen geeignet sind, z. B. für Verkaufsdisplays, Verglasungen und Beleuchtungsarmaturen. Wir bieten ein umfassendes Angebot an Acrylglasplatten in verschiedenen Stärken, von dünnen Acrylglasplatten wie 1 mm (die häufig für Spiegel-Acrylglasplatten verwendet werden) bis hin zu dicken Acrylglasplatten für strukturelle Zwecke. Es ist wichtig, die Anforderungen Ihrer Anwendung zu verstehen - ob Sie die optische Perfektion von klaren, gegossenen Acrylplatten oder die Kosteneffizienz und Formbarkeit von extrudiertem Acryl benötigen - und unser Team kann Ihnen bei der Auswahl helfen. Wir bieten verschiedene Optionen für Acrylglasplatten an, darunter klare Acrylglasplatten, farbiges Acrylglas, undurchsichtige und durchscheinende Oberflächen, um unterschiedliche ästhetische und funktionale Anforderungen zu erfüllen.

Präziser Zuschnitt von Acrylglas und Polierdienstleistungen

Eine unserer Hauptstärken als Hersteller von Acrylglasplatten ist der Zuschnitt nach Maß. Wir wissen, dass der Erhalt von Materialien in den exakten Abmessungen für unsere Kunden eine erhebliche Zeit- und Arbeitskostenersparnis bedeutet, insbesondere bei Großprojekten und Großhändlern. Durch den Einsatz fortschrittlicher CNC-Fräs- und Laserschneidetechnik können wir hochpräzise Schnitte mit engen Toleranzen durchführen. Ganz gleich, ob Sie einfache rechteckige Platten, komplexe kundenspezifische Formen oder komplizierte Designs für die Lasergravur benötigen, unsere hochmodernen Maschinen stellen sicher, dass Ihre Acrylplattenkomponenten bei der Ankunft einsatzbereit sind.

Neben dem einfachen Schneiden bieten wir Zuschnittdienste an, die auch Optionen zur Kantenbearbeitung wie Polieren umfassen. Polierte Kanten sorgen für ein sauberes, hochwertiges Finish, entfernen Sägespuren und stellen die optische Klarheit der Kante der klaren Acrylplatte oder des farbigen Acryls wieder her. Dies ist besonders wichtig für Vitrinen, Möbelteile und alle Anwendungen, bei denen die Kante der Acrylglasplatte sichtbar ist. Wir können auch abgerundete Kanten für Sicherheits- und ästhetische Zwecke liefern. Unser System zur Berechnung von Zuschnitten (interner Prozess) gewährleistet Genauigkeit, wenn Sie kundenspezifische Abmessungen bestellen, und vereinfacht den Spezifikationsprozess für Ihren Bedarf an Acrylglasplatten. Von Plexiglasplatten, die für einfache Einrahmungen zugeschnitten werden, bis hin zu kunstvoll lasergeschnittenen Acrylplastikenc Komponenten für Werbedisplays, unsere Präzision sorgt dafür, dass Ihr Projekt mit perfekt vorbereiteten Materialien beginnt. Sie können leicht Acrylglasplatten in Sondergröße bestellen direkt über unseren B2B-Prozess.

Vergleich der Eigenschaften von Acrylglasplatten:

| Eigentum | Gegossene Acrylglasplatte | Extrudierte Acrylglasplatten | Glas (zum Vergleich) | Polycarbonat |

| Schlagzähigkeit | Höher als Extrudiert | Gut | Niedrig | Extrem hoch |

| Optische Klarheit | Ausgezeichnet | Sehr gut | Ausgezeichnet | Gut |

| Dicke Tol. | Breiter | Enger | K.A. | Enger |

| Tiefziehen | Gut | Ausgezeichnet | Nein | Gut |

| Chemikalienbeständig. | Besser als stranggepresst | Gut | Ausgezeichnet | Gut |

| Oberflächenhärte | Härter | Weicher | Sehr schwer | Weicher |

| Kosten | Höher | Unter | Variiert | Höher als Acryl |

(Hinweis: Die Werte sind relative Vergleiche)

Vielfältige Produktpalette an Acrylglasplatten für jede Anwendung

Unsere Möglichkeiten gehen weit über Standard-Acrylglasplatten hinaus. Als engagierter Lieferant von Acrylplatten bieten wir eine große Auswahl an Plexiglas- und Acrylplattentypen für eine breite Palette von Anwendungen. Ganz gleich, ob Sie funktionale Materialien oder dekorative Elemente benötigen, wir haben die Acrylplatten und -typen, die Sie benötigen.

Unsere Produktlinien umfassen:

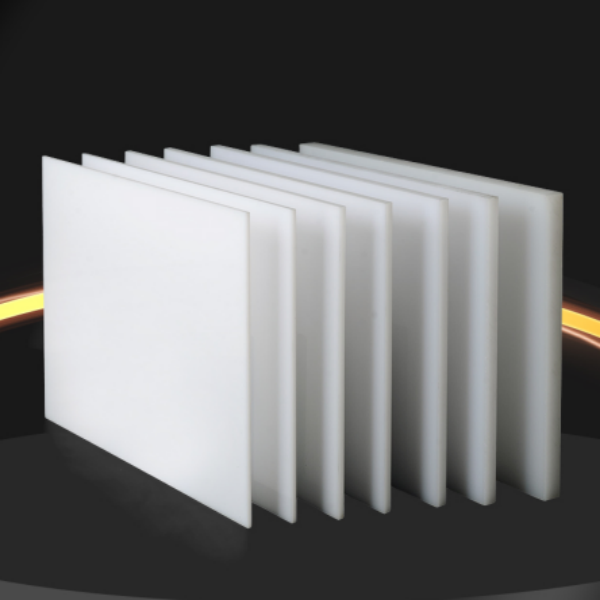

- Klare Acrylglasplatte: Das standardmäßige, hochtransparente Acrylplexiglas ist ideal für Verglasungen, Displays und Schutzwände. Erhältlich als klare gegossene Acrylplatten und extrudiert.

- Farbige Acrylglasplatten: Erhältlich in einem Spektrum von transparenten und undurchsichtigen Farben (rote Acrylglasplatten, blaue Acrylglasplatten, grüne Acrylglasplatten usw.) für lebendige Beschilderungen, Designelemente und Branding. Wir bieten sowohl Standard- als auch kundenspezifische farbige Acrylglasplatten an.

- Acrylglasplatte mattiert: Bietet eine matte Oberfläche für Lichtstreuung, Sichtschutzwände und anspruchsvolle Designästhetik. Es ist eine beliebte Option für lichtdurchlässige Acrylplatten.

- Acryl-Spiegel-Blatt: Leichte und bruchsichere Alternative zu Glasspiegeln, ideal für Displays, Innenarchitektur und Sicherheitsanwendungen. Erhältlich in verschiedenen Farben.

- Strukturierte Acrylglasplatte: Mit Mustern (gemusterte Acrylplatten, geriffelte Acrylplatten) für dekorative Zwecke, zur Lichtstreuung oder zur Verbesserung des Sichtschutzes.

- Spezialisierte Blätter: Einschließlich UV-Acrylplatten für Außenanwendungen, Acryl-Diffusorplatten für die Beleuchtung, 2-farbige Acrylplatte für Gravuren und dicke Acrylplatten für anspruchsvolle strukturelle Anwendungen.

Dieses vielseitige Acrylglas-Sortiment stellt sicher, dass Projektmanager, Designer und Großhändler praktisch jede Art von Plexiglas oder Acrylglasplatten beziehen können, die sie für Anwendungen benötigen, die von Einzelhandelsausstattungen und architektonischen Elementen bis hin zu industriellen Komponenten und Werbematerialien reichen. Wir sind in der Lage, Bestellungen für Standardformate wie 4×8 Acrylglasplatten zu bearbeiten oder vollständig maßgeschneiderte Lösungen zu liefern. Unsere Erfahrung als Fabrik für Acrylglasplatten garantiert, dass wir die Nuancen jedes Acrylplattentyps kennen, von Chemcast- und Acrylit-Varianten bis hin zu Plexiglas- und Lucit-Äquivalenten. Arbeiten Sie mit uns zusammen, Ihrer umfassenden Quelle für Acrylglasplatten für Ihr nächstes Projekt oder Ihren Lagerbedarf. Kontakt um Ihre spezifischen Bedürfnisse zu besprechen und ein individuelles Angebot zu erhalten.

10 Dinge, die Sie beim Kauf von Produkten aus China beachten sollten

Hilfe-Center

Haben Sie eine Frage? Bitte prüfen Sie diese Frage und Antworten

Ja, wir verwenden 100% Premium-Acrylglas (PMMA) ohne recycelte Bestandteile, das für alle Produkte eine hervorragende Klarheit, UV-Beständigkeit und langfristige Haltbarkeit gewährleistet.

Wir sind für unser Qualitätsmanagement nach ISO 9001 zertifiziert und erfüllen die Umweltstandards REACH/SGS. Kundenspezifische Zertifizierungen (z. B. FDA für lebensmittelechtes Acryl) können auf Anfrage erteilt werden.

Standardartikel: 7-10 Tage. Sonderanfertigungen: 12-18 Tage je nach Komplexität. Eilaufträge können besprochen werden.

Ja. Wir bieten CNC-Schneiden, Lasergravieren, Thermoformen und Kantenpolieren. Senden Sie uns CAD-Dateien/DXF-Entwürfe für ein sofortiges Angebot. Mindestbestellmenge: 10 Stück pro Entwurf.

Standarddicke: 1mm-15mm. Farben: Klar, matt, 16+ transparente Farben und kundenspezifische Pantone-Farben (MOQ 500kg). Toleranz: ±0,2 mm.

Wir stellen 3 kostenlose Muster im Format A4 zur Verfügung. Der Kunde trägt die DHL/UPS-Versandkosten. Vorlaufzeit für Muster: 72 Stunden.

Farbabweichungen bei Acrylglasplatten können aufgrund verschiedener Faktoren auftreten, z. B:

Unterschiede zwischen den Produktionschargen: Leichte Änderungen der Pigmentkonzentration oder der Rohstoffe zwischen den Chargen.

Herstellungsbedingungen: Schwankungen der Temperatur, des Drucks oder der Aushärtezeit während der Produktion.

UV-Belastung: Längeres Sonnenlicht kann zum Verblassen oder zu Farbveränderungen führen.

Schneiden/Bearbeiten: Die beim Schneiden oder Bearbeiten entstehende Wärme kann die Oberflächenfarbe vorübergehend verändern.

An einem kühlen, trockenen, UV-geschützten Ort und vor direkter Sonneneinstrahlung geschützt lagern.

Lassen Sie die Schutzfolien bis zum Einbau intakt, um Kratzer oder chemische Reaktionen zu vermeiden.

Vermeiden Sie es, die Blätter mit ungleichmäßigem Druck zu stapeln, da dies zu spannungsbedingten Verfärbungen führen kann.

Kundenspezifische Farben verringern zwar die Risiken, aber absolute Konsistenz ist eine Herausforderung. Fordern Sie immer ein Vorproduktionsmuster an und vereinbaren Sie mit dem Lieferanten einen Toleranzbereich.