-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Clean & Maintain Acrylic Sheets: 10 Tips for Lasting Shine

Table of Contents

Introduction

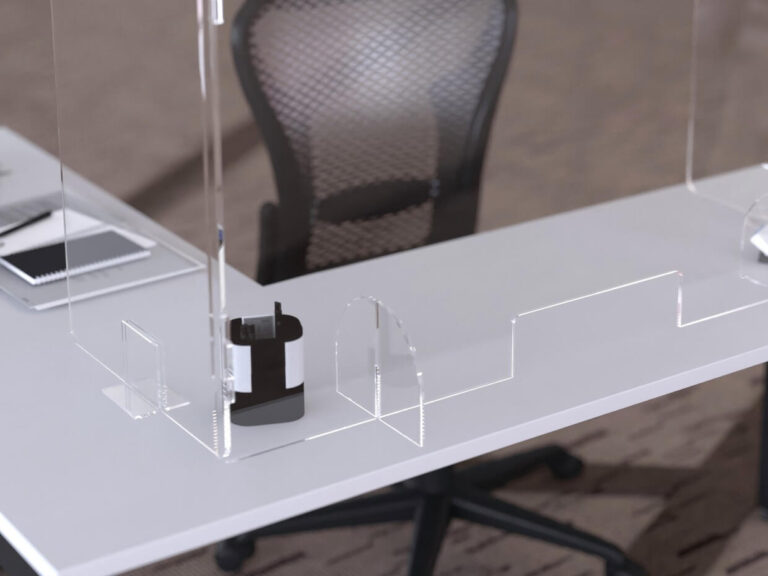

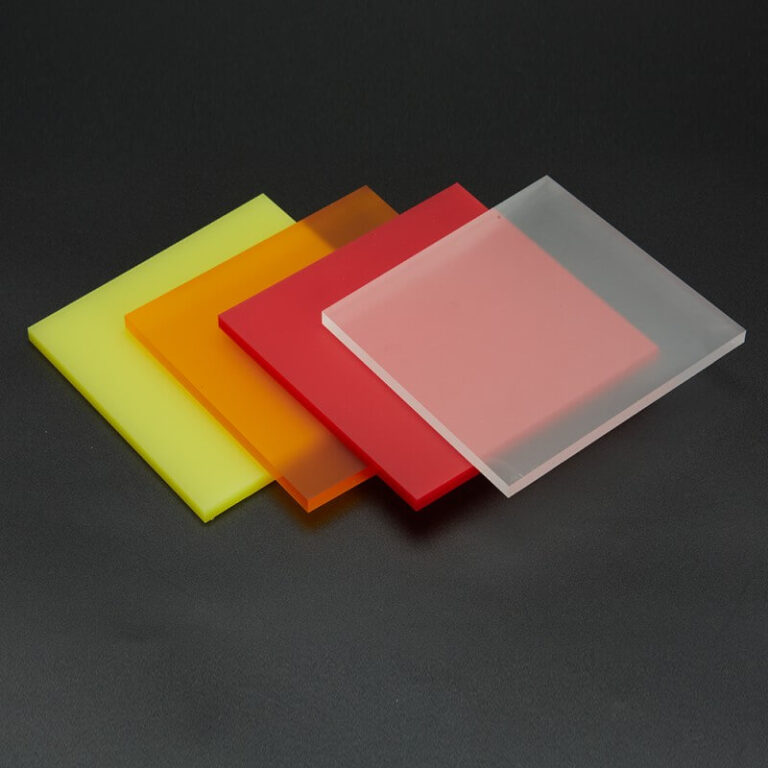

Acrylic sheets (plexiglass) are widely used in home decoration, advertising signs, aquariums and other fields due to their high transparency, lightness and weather resistance. However, improper cleaning methods may cause scratches, yellowing and even cracking. This article combines the advice of industry experts with scientific experimental data to systematically sort out the 10 core tips for cleaning and maintenance of acrylic sheets to help you easily extend the life of the sheets and keep them crystal clear.

Daily Cleaning: Canned air + microfiber cloth to clean acrylic sheet

Argument: Canned air is the best tool for removing surface dust.

Argument:

- Canned air blows away dust through high-pressure airflow to avoid scratches caused by direct friction (recommended by the American Cleaning Association).

- Choose canned air with anti-static additives (such as the Dust-Off brand) to reduce secondary adsorption of dust.

- Use a microfiber cloth to wipe off residual particles, avoid using paper towels or rough cloths (refer to 3M Cleaning Guide).

Deep decontamination: warm soapy water + soft sponge for acrylic sheet

Argument: Warm soapy water is a safe and effective decontamination agent.

Argument:

- Neutral soap (such as Dawn) can break down grease and does not corrode the surface (EPA detergent safety standard).

- The water temperature must be controlled below 40℃, high temperature will cause acrylic to deform.

Scratch repair of acrylic sheet: staged sanding method

Argument: Step-by-step sanding can repair shallow scratches.

Argument:

- Use 800 grit sandpaper to rough sand, and evenly treat the scratched area in a circular motion.

- Use 2000 grit sandpaper for fine grinding, and finally polish with 3000 grit (Mirka Abranet sandpaper is recommended as the tool).

- Spray water to cool down the whole process to avoid friction heat causing deformation of the plate.

Flame polishing: quickly restore gloss

Argument: Controlled flame can melt the surface to achieve polishing.

Argument:

- The acetylene welding torch needs to maintain a neutral flame and quickly sweep it 1 inch away from the plate.

- Single treatment should not exceed 3 seconds to prevent local overheating and cracking.

Prohibited chemical solvents: alcohol and acetone

Argument: Alcohol solvents can cause acrylic to become brittle.

Argument:

- Isopropyl alcohol concentration exceeding 10% may cause micro cracks (experiment of Journal of Polymer Materials).

- Acetone will dissolve the surface of acrylic, causing permanent fogging (see Material Failure Database for examples).

Anti-static maintenance: anti-static spray

Argument: Electrostatic adsorption of dust is a common problem of acrylic.

Argument:

- Spraying an antistatic agent (such as Novus 888) once a month can reduce dust adhesion by 90% (user measured data).

- Avoid using acrylic in a dry environment, and the humidity must be maintained at 40%-60% (refer to ASHRAE environmental standards).

UV protection: film or coating

Argument: UV rays are the main cause of acrylic yellowing.

Argument:

- UV blocking film (such as 3M UV Protective Film) can delay aging for more than 5 years (Material Aging Research).

- Polishing wax containing UV absorber (such as Meguiar’s PlastX) has both cleaning and protective functions.

Scraper use skills: angle and strength

Argument: Plastic scrapers can safely remove stubborn stains.

Argument:

- Keep the scraper at a 30° angle to the surface and avoid vertical pressure.

- Use soapy water to lubricate and reduce scraping resistance (industrial cleaning standard ANSI/BIFMA).

Storage specifications: upright + dust cover

Argument: Improper storage can easily cause the board to bend.

Argument:

- Acrylic sheets should be stored upright with an inclination angle of no more than 10° (Plastic Storage Guide).

- Use non-woven dust covers to avoid direct coverage with plastic film (easy to stick).

Regular Inspection: Preventive Maintenance

Argument: A comprehensive inspection once a month can avoid potential damage.

Argument:

- Use LED side light detection to find invisible cracks.

- Apply silicone sealant to the edges to prevent moisture from penetrating and delamination.

FAQs of Cleaning Acrylic Sheets

How often should acrylic boards be cleaned?

Daily floating dust is immediately treated with canned air, and a comprehensive inspection + deep cleaning is done once a month.

Will the scraper damage the surface?

Proper use of a plastic scraper (30° angle + soapy water lubrication) can safely remove dirt, and vertical pressure is prone to scratches.

Can I use alcohol to clean acrylic sheets?

No! Alcohol (concentration>10%) will cause acrylic to become brittle and crack. It is recommended to use a water-based cleaner.

Conclusion

The cleaning and maintenance of acrylic sheets requires both scientific methods and detailed operations. From daily dust removal to deep repair, from chemical taboos to environmental protection, each step directly affects the life of the sheet. Following the above 10 tips and using tools and products recommended by authoritative organizations can ensure that acrylic sheets remain as good as new all year round. For more information on professional maintenance plans, please refer to the latest guidelines of the Sanyu Acrylic Sheets.

Through systematic maintenance, acrylic sheets can not only maintain their beauty, but also play their functional value as “transparent metal”.