-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Clean Acrylic Panels Perfectly – Avoid Costly Errors

A true guide to acrylic maintenance derived from nearly 30 years of professional manufacturing, making your sheet look like new for ten years.

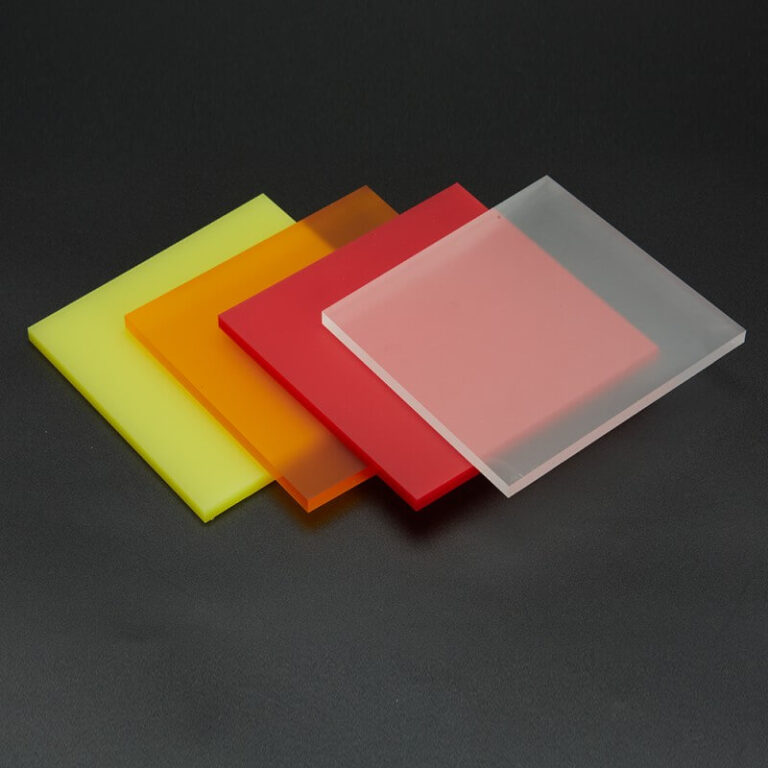

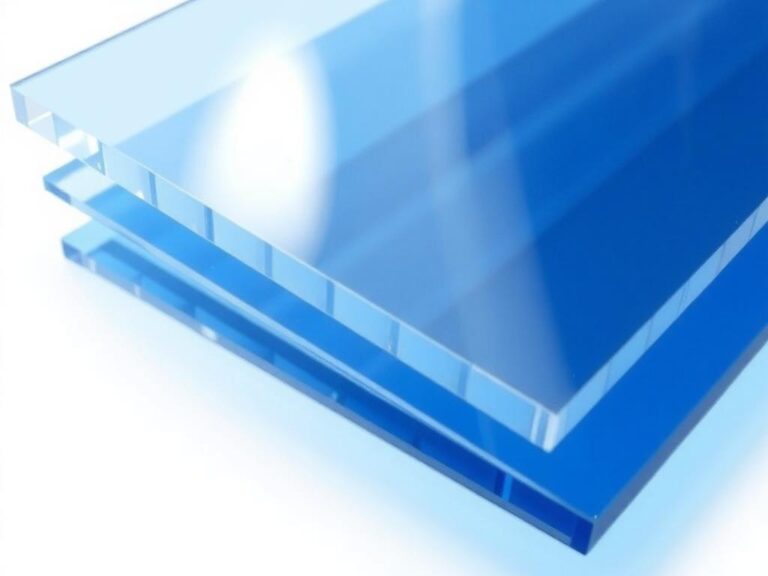

In the world of materials that pursue transparency and durability, acrylic sheets stand out for their excellent optical properties and impact resistance. As a company with 28 years of precision manufacturing experience, Sanyu Plastics knows that 90% of the secret to acrylic’s brilliance lies in scientific maintenance.

This guide will reveal the deep logic and practical skills of acrylic cleaning, helping you avoid common traps and make each sheet a durable visual masterpiece.

1. Understanding the fragility of acrylic: the truth at the molecular level

The surface hardness of acrylic (PMMA) is much lower than that of glass, and its molecular structure is extremely sensitive to certain solvents. Chemicals in strong cleaners can erode the surface, causing irreversible “cracking” or fogging. The American Chemistry Council pointed out that incorrect cleaning is the primary human factor in the decline of the optical properties of acrylic sheets. When choosing a cleaning solution, you must base it on its scratch-prone and solvent-averse properties.

2. Six-step daily cleaning method: the key to traceless protection

- Pre-dust removal: Use compressed air or a soft brush to remove surface particles to avoid scratches caused by subsequent wiping.

- Prepare solution: Mix a small amount of additive-free detergent (such as Dawn Original) with warm water (below 40°C).

- Special tools: Use only microfiber cloth and wipe in a straight line in one direction. Experiments have shown that circular wiping increases the risk of micro scratches by 35%.

- Deep rinse: Use running water to thoroughly rinse off soap residue – residue is the invisible killer that causes acrylic to fog.

- Scientific drying: Place vertically to drain naturally, or immediately press with a dry microfiber cloth to absorb water.

- Frequency control: 1-2 times a week in daily environments, and increase to 3 times in high-contact areas (such as display cabinets).

3. Overcoming stubborn stains: Special cleaning solutions

- Glue residue: Apply a special acrylic glue remover (such as Novus #1) to soften and then scrape gently

- Scale deposit: Apply white vinegar solution (vinegar: water = 1:10) for 5 minutes and then wipe

- Oily handwriting: Dissolve with isopropyl alcohol (concentration below 70%) using a cotton swab The British Museum Association’s Guide to Cultural Relics Protection emphasizes that isopropyl alcohol concentrations exceeding 70% will cause swelling of the acrylic surface and must be strictly diluted for use.

4. Nine fatal cleaning misunderstandings: invisible traps that destroy boards

- Ammonia glass cleaner: causes chemically corrosive atomization (common brands such as Windex)

- Paper towels/rough rags: wood fibers are equivalent to #800 sandpaper and continuously wear the surface

- High-pressure water gun flushing: water flow impact causes stress cracks

- Solvent direct spray: acetone, gasoline, etc. dissolve polymer chains

- Blade hard scraping stains: leaving permanent grooves

- High-temperature steam cleaning: over 90℃ causes board deformation

- Wax-containing car care agent: forms a greasy film layer to absorb dust

- Stacking unprotected boards: handling friction causes mesh scratches

- Direct ultraviolet disinfection lamp: accelerates the yellowing process of materials

5. Preventive maintenance: reduce cleaning needs from the source

- Install protective film: Sanyu Plastics original protective film can reduce the scratch rate during installation by 80%

- UV-resistant model: UV-stable acrylic (such as PLEXIGLAS® UV-resistant grade) should be selected for outdoor use

- Frame reserved expansion joint: 3mm gap is reserved for each meter length (ISO 7823 standard)

- Antistatic treatment: Antistatic agent is used in retail display areas to reduce dust absorption

6. Cleaning specifications for special scenarios

| Application scenarios | Cleaning tips | Prohibited substances |

|---|---|---|

| Aquarium | Cotton cloth + white vinegar solution | Chlorine-containing disinfectant, detergent |

| Medical protective screen | Hydrogen peroxide wipes (concentration <3%) | Quaternary ammonium disinfectant |

| Food operation table | Ethanol solution (concentration 70%) | Benzalkonium chloride |

| Building curtain wall | Special acrylic cleaner + soft brush | Abrasive particle decontamination powder |

7. Golden rules for storage and transportation

- Vertical storage: tilt angle > 10° to avoid deformation due to weight

- Environmental control: temperature 18-25℃/humidity 40-60% (refer to ASTM D3929 standard)

- Isolation protection: acid-free thin cotton paper (such as glass mildew-proof paper) between sheets

- Handling specifications: wear cotton gloves to hold the edges and corners, and it is strictly forbidden to drag on the ground

8. Replacement decision tree: When to give up repair

When any of the following situations occurs, replacement is better than repair:

✅ Scratch depth > 0.3mm and density > 30/10cm²

✅ Stress crack length > 1/3 of the short side of the board

✅ Yellowing index ΔY > 10 (ISO 4582 standard)

✅ Surface haze > 15% (ASTM D1003 measurement)

The crystal clearness of acrylic board is the crystallization of technology and maintenance art. Every correct wipe prolongs the journey of light, and every bit of scientific maintenance fights against the erosion of time. Mastering these eight core rules means:

- Say goodbye to the dual threats of chemical atomization and physical scratches

- Establish a full life cycle maintenance logic from installation to disposal

- Understand the material properties at the molecular level to achieve precise care

- Make acrylic products as bright as they were when they first saw them in ten years

When your display cabinet is still as clear as crystal, and your aquarium is still as transparent as air, this is the deepest respect for the material. The value of this guide lies not only in saving replacement costs, but also in protecting the unworn visual purity – this is exactly the fundamental reason why acrylic conquers the world.