-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Acrylic sheet: Transparent Revolution Reshapes The Modern Industrial Ecology

Abstract

Acrylic sheet (PMMA), as a lightweight alternative to glass, has become a core material in the fields of construction, medical care, transportation, advertising, etc. due to its high light transmittance, weather resistance, easy processing and environmental protection. This article systematically analyzes how acrylic sheet promotes industrial upgrading through the “transparent revolution” from the dimensions of technical characteristics, application scenarios, market trends and sustainable development, and looks forward to its potential in the future smart and green economy.

1. Technical characteristics: physical and chemical advantages of acrylic sheet

- Optical performance Acrylic has a light transmittance of up to 92%, which is better than ordinary glass (about 85%-89%), and can effectively reduce light scattering, making it an ideal choice for optical lenses, LED screens and lighting equipment. For example, Mitsubishi Chemical’s high-transmittance acrylic sheet is widely used in high-end display panels, with a surface hardness of up to 89 degrees Rockwell, and significantly improved scratch resistance.

- Mechanical strength and lightweight Acrylic has an impact strength 7-18 times that of glass, and its density is only half that of glass (1.18g/cm³). In the lightweight design of automobiles, acrylic headlight covers can reduce the body load by about 30% while meeting safety standards.

- Environmental adaptability Its UV resistance and temperature resistance range (-40℃ to 80℃) make it last more than 10 years in outdoor billboards, highway soundproof screens and other scenes, far exceeding traditional materials.

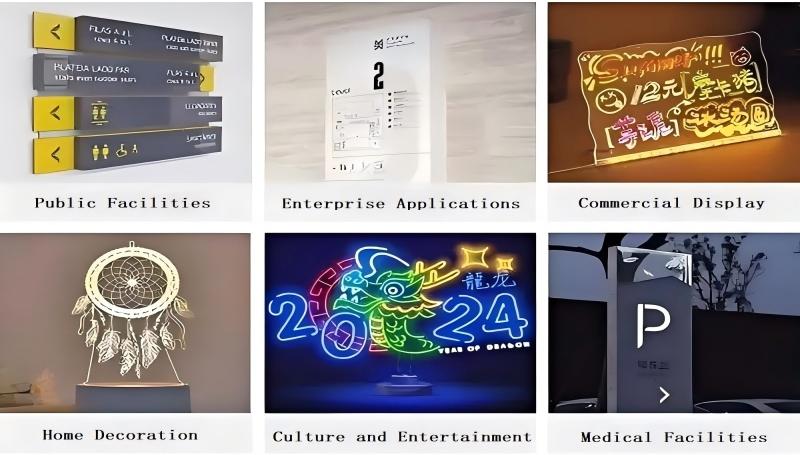

2. Application scenarios: from traditional manufacturing to emerging fields

- Architecture and interior design

- Modern building structure: Acrylic panels are used for skylights, skylights and curved curtain walls. For example, the curved dome of Dubai Shopping Center uses cast acrylic panels, which have both structural strength and aesthetic effects.

- Interior decoration: Translucent stair handrails, partition walls and art installations are made through hot bending technology to achieve complex shapes and enhance the sense of spatial transparency.

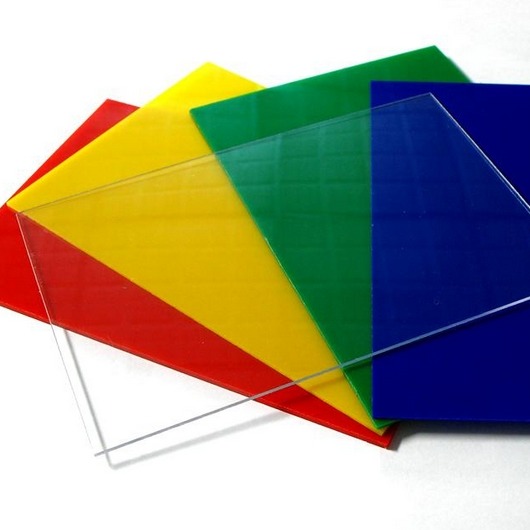

- Advertising and Commercial Display In the global advertising signage market, acrylic light boxes account for more than 60%. It has high color saturation and can be customized with UV printing technology. For example, the acrylic display racks in Apple retail stores increase the product transmittance to 95%.

- Medical and Health Industry

- Sterile Equipment: Surgical instrument trays and PCR test kits are made of medical-grade acrylic, which is resistant to chemical corrosion and can be sterilized by high temperature and high pressure.

- Protective Barrier: During the COVID-19 pandemic, acrylic sheets were widely used in hospital isolation cabins and protective masks, and their shatterproof properties ensured the safety of medical staff.

- Transportation and Automobile Industry

- Aviation and Rail Transportation: Aircraft windows and high-speed train windshields use multi-layer composite acrylic with a compressive strength of 200MPa, while reducing energy consumption.

- New Energy Vehicles: The dashboard shell of Tesla Model 3 uses anti-glare acrylic sheets to reduce visual fatigue when driving.

- Electronics and Optical Technology

- Consumer Electronics: Mobile phone screen protectors and VR glasses lenses rely on the high light transmittance and blue light resistance of acrylic, such as the Samsung Galaxy series screen with a light transmittance of 91%.

- Optical Instruments: Microscope slides and laser lenses are precision-molded with acrylic to reduce optical distortion.

- Sustainable Design

- Circular Economy: Plaskolite and other companies have launched recycled acrylic sheets with a recycling rate of over 70%, reducing the consumption of petroleum-based raw materials.

- Green Building: In LEED certification projects, acrylic lighting systems can reduce building energy consumption by 15%-20%, contributing to carbon neutrality goals.

III. Market Trends and Strategic Insights

- Global Market Growth According to QYResearch data, the global acrylic sheet market size will reach US$4.3 billion in 2024, and is expected to exceed US$6.3 billion in 2031, with a compound annual growth rate of 5.2%. The Asia-Pacific region leads with a 40% market share, and China’s production capacity accounts for 35% of the world.

- Technology iteration and competition pattern

- High-end competition: Mitsubishi Chemical and Trinseo develop anti-fingerprint acrylic sheets through nano-coating technology, with a premium rate of over 30%.

- Regional production: In order to circumvent US tariff barriers, Chinese companies set up factories in Southeast Asia, such as Xintao Acrylic’s annual production line of 100,000 tons in Vietnam.

- Policy and risk response

- Compliance upgrade: EU REACH regulations require that VOC emissions of acrylic products be less than 0.1%, which promotes companies to use water-based adhesives.

- Supply chain resilience: After the COVID-19 pandemic, leading companies have shortened the raw material inventory cycle to 7 days through digital procurement platforms.

IV. Future Outlook: Smart Materials and Cross-border Integration

- Smart Surface Technology Acrylic sheets embedded with a conductive layer can be used for touch interactive screens, and the acrylic center console of the BMW iNEXT concept car has realized gesture control.

- Biomedical Innovation 3D printed acrylic bone models and microfluidic chips accelerate the development of personalized medicine. MIT laboratory uses acrylic microchannels to achieve single-cell analysis.

Summary

Acrylic sheets are reshaping the ecological chain from traditional manufacturing to high-tech industries with their “transparent, strong and plastic” characteristics. With the advancement of regenerative technology, smart coatings and regionalized production, acrylic is not only a material, but also a symbol of sustainable development and innovative design. In the future, its application in smart cities, bioengineering and space exploration will usher in a new round of industrial revolution.

References

- QYResearch “Global Acrylic Sheet Market Size Report” link

- Mitsubishi Chemical High Transparency Acrylic Technology White Paper

- China Plastics Processing Industry Association “2025 Acrylic Industry Green Transformation Guide”