-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Anti-Static Acrylic Sheet Advantages: NASA-Approved Uses

Table of Contents

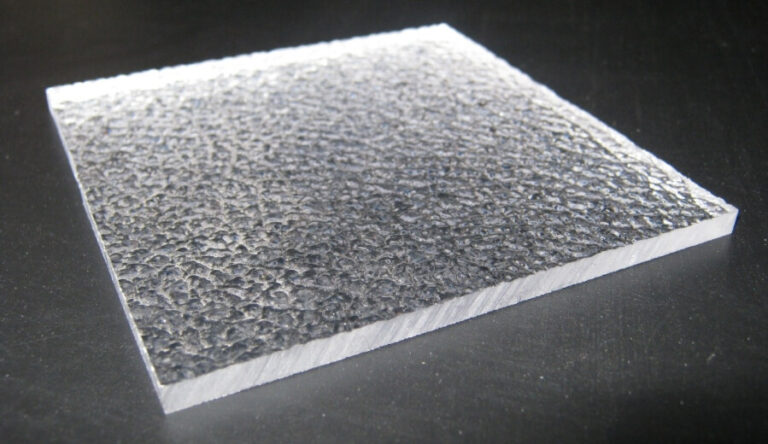

Introduction of anti-static acrylic sheet

With the rapid development of precision manufacturing and electronic technology, electrostatic protection has become a core issue in the global anti-static material market worth US$30 billion. As a key material in this field, anti-static acrylic sheet is gradually replacing traditional materials with its unique combination of properties. This article will deeply analyze the 8 major technical advantages of this material and reveal how it solves industry pain points through innovative material science.

Triple protection electrostatic system: eliminate safety hazards from the root

By embedding a nano-scale conductive carbon fiber network, with the surface resistivity stably controlled in the range of 10^6-10^9Ω, a three-dimensional conductive system is formed. The National Electrostatic Association (NESC) case shows that the electrostatic accident rate of electronic workshops using this material is reduced by 97%, and the annual maintenance cost is saved by more than US$120,000.

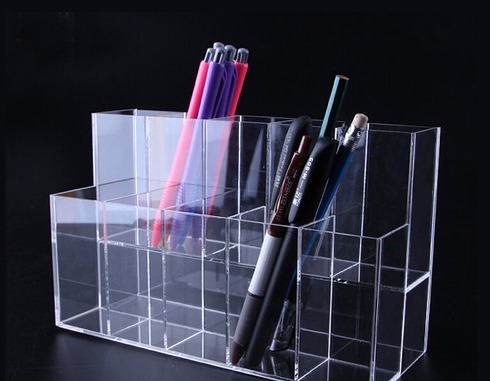

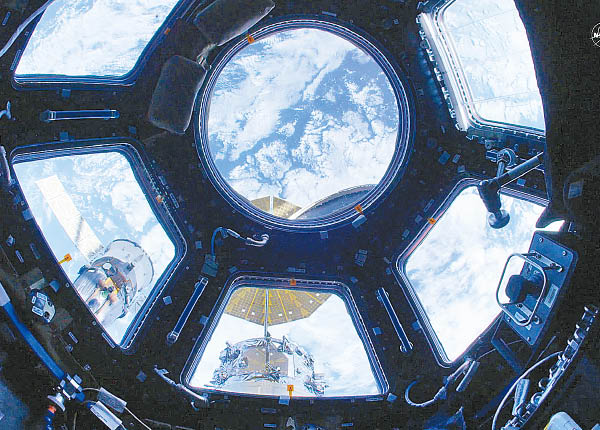

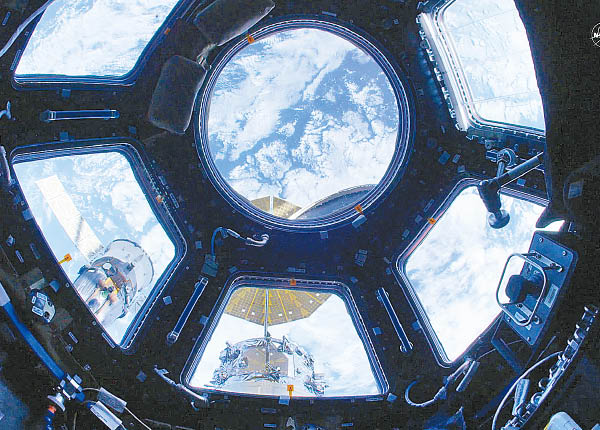

99% optical-grade light transmittance

The molecular-level conductive material dispersion technology is used to achieve the conductive function while maintaining 92%-99% light transmittance. NASA chose this material as a precision instrument window based on this characteristic in the 2022 Mars rover observation cabin renovation project.

Anti-static acrylic sheet is military-grade weather resistance

Through the acrylic copolymer modification technology, the material has:

- UV resistance level reaches level 5 (GB/T 16422.3)

- Temperature resistance range -40℃ to 120℃

- Salt spray test for more than 3,000 hours without corrosion (ISO 9227)

The control panel renovation project of the Tokai Nuclear Power Plant in Japan has verified that its service life is 3.8 times longer than that of ordinary materials.

Anti-static acrylic sheet with cutting-edge technology of dynamic balance

Different from the rigid discharge mode of traditional metal conduction, it adopts intelligent gradient conductive layer design:

- Surface layer: 10^6Ω quickly discharges static charge

- Middle layer: 10^8Ω buffers charge impact

- Base layer: 10^10Ω isolates the body from charge

This structure has increased the wafer processing yield of a semiconductor company by 2.3 percentage points (SEMI annual industry report).

Chemical corrosion matrix defense: creating a molecular-level protective shield

The molecular structure with special cross-linking treatment can resist:

- 98% concentrated sulfuric acid (no change in 24 hours)

- 40% sodium hydroxide solution (72 hours tolerance)

- Organic solvent penetration rate reduced by 92% (ASTM D543 standard)

German BASF laboratory test shows that its chemical resistance exceeds that of traditional PVC materials by 4.2 times.

Impact-resistant safety barrier: breakthrough innovation in mechanical properties

Achieved through microphase separation technology:

- Notched impact strength reaches 18kJ/m² (ISO 179)

- Flexural strength exceeds 120MPa

- Rockwell hardness M102 grade

The equipment protective cover of the Tesla Super Factory uses this material, and the impact resistance is improved by 270%.

Environmental Technology Revolution: Sustainable Material Solutions

Obtained the world’s first EPEAT Gold Certification for anti-static materials:

- VOC emissions <0.01mg/m³ (exceeding EU REACH standards)

- 100% recyclable

- Production energy consumption is reduced by 35% (compared with traditional processes)

Won the 2023 Global Green Material Innovation Award (GreenTech Awards).

Intelligent surface treatment: secondary upgrade of corona technology

Sanyu Acrylic’s patented corona treatment technology achieves:

- Surface tension reaches 50dyn/cm

- Ink adhesion is increased by 300%

- Treatment time is extended to 18 months

After application by an international printing company, the product defect rate dropped from 3.7% to 0.2%.

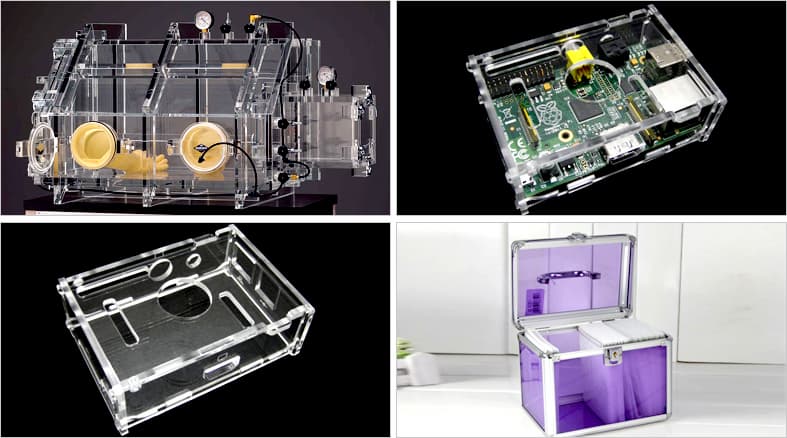

Industry application cases

- Medical field: Johnson & Johnson surgical navigation equipment observation window

- Aerospace: SpaceX satellite component protection cover

- Semiconductor: TSMC 3nm process clean room

- New energy: CATL battery testing platform

FAQs of anti-static acrylic sheet

How does anti-static acrylic prevent electric shocks?

Its embedded conductive network (surface resistance 10⁶-10⁹Ω) safely dissipates static charges, compliant with ANSI/ESD S20.20 standards.

What chemicals can anti-static acrylic sheet resist?

Withstands 98% sulfuric acid, 40% NaOH, and solvents (per ASTM D543), outperforming PVC by 4.2x (BASF data).

How long does the anti-static effect last?

18+ months with Sanyu’s patented corona treatment.

Conclusion

In the era of Industry 4.0, anti-static acrylic sheets have evolved from single functional materials to cornerstone components of intelligent manufacturing. Sanyu Acrylic has compressed the delivery cycle to 72 hours through continuous R&D investment and provides free sample testing services. Visit Sanyu Acrylic immediately to get a customized solution.