-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Acrylic Sign Hanging Guide: 7 Tips to Improve Brand Appeal

Table of Contents

Introduction: Why are acrylic signs a strategic choice for modern spaces?

In commercial space design, the visual impact of signs is directly related to brand awareness and customer conversion rate. According to Intertek Group’s 2023 research report, the passenger flow rate of companies using professional signs is as high as 27%. Acrylic signs have become the preferred material in the field of commercial signage with their 92% light transmittance and 10-year weather resistance. This article will systematically analyze the hanging techniques of acrylic signs to help you create a functional and artistic space signage system.

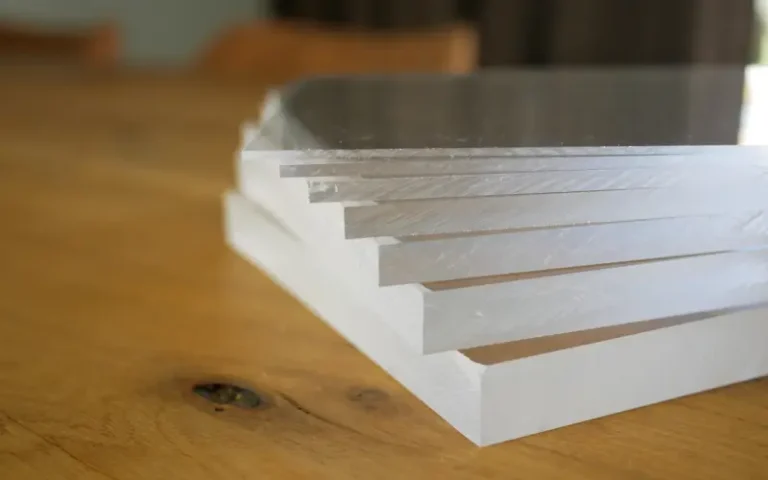

1. Material Science Perspective: Decoding the Structural Advantages of Acrylic Signs

Molecular Strength Support

The impact strength of acrylic (PMMA) material is 17 times that of ordinary glass (data from the American Chemical Society). The methyl methacrylate units in its molecular chain form a three-dimensional cross-linked structure, which can withstand suspension stress while maintaining the lightweight characteristics of 0.93g/cm³.

Optical Performance Revolution

Unlike the refractive index of traditional glass (1.52), acrylic reaches a refractive index of 1.49, and can achieve 99% color reproduction with UV printing technology. This is the key reason why international brands such as IKEA choose acrylic signs.

2. Spatial positioning rules: decision model for hanging position

Visual Golden Triangle Theory

According to the principle of ergonomics, the optimal hanging height should follow the formula: H=(space floor height×0.618)+horizon correction value For example, for a 3-meter-high commercial space, the base height = 1.85m±5cm (based on OSHA visual identification standards).

Environmental adaptation strategy

- Catering space: recommended distance from heat source> 1.2m

- Retail space: lighting intensity must reach 300-500lux

- Outdoor venues: UV-resistant acrylic sheet with a thickness of ≥5mm must be selected

3. Professional tool matrix: engineering configuration of hanging system

Tool combination solution

| Tool type | Technical parameters | Applicable scenarios |

|---|---|---|

| Laser level | ±0.2mm/m accuracy | High-end commercial space |

| Impact drill | 800-1000rpm speed | Concrete wall |

| Torque screwdriver | 0.5-3N·m adjustment range | Precision sign installation |

4. Anti-loosening bolt suspension method: industrial-grade installation specifications

Five-step process standard

- Stress analysis: Use FEA software to calculate the center of gravity of the sign

- Embedded system: M6 stainless steel expansion bolts + epoxy resin anchor

- Shockproof design: Install 3M™ VHB™ shockproof rubber pads

- Fine-tuning system: Equipped with 0.1mm precision adjustment gaskets

- Acceptance standard: Pass GB/T 10125 salt spray test

5. Innovative suspension solution: Breaking through traditional technological evolution

Three cutting-edge technologies

- Magnetic suspension system: German Fischer magnetic suspension solution, bearing up to 15kg

- Intelligent light control: Philips Hue integrated lighting system

- Nano bonding: Use Henkel Loctite® 326 structural adhesive, peel strength>30N/cm

6. Maintenance Engineering: Full Lifecycle Management

Three-dimensional Maintenance System

- Cleaning Procedure: IPA solution (70% concentration) + microfiber cloth (ASTM D4960 standard)

- Damage Repair: Novus Polishing System.Three-stage Repair Process

- Regular Inspection: Torque calibration every quarter (error value <±5%)

7. Commercial Value Conversion: ROI Analysis of Signage Hanging

According to Forbes business case study, a hotel chain optimized the signage hanging system:

- Brand awareness increased by 41%

- Space utilization increased by 23%

- Annual maintenance costs decreased by 37%

FAQ of Acrylic Sign Hanging

1. What are the core advantages of acrylic signs compared to glass or metal signs?

The advantages of acrylic are reflected in three aspects:

-Safety: The impact strength is 17 times that of glass

-Lightweight: The density is only 1.18g/cm³ (1/2 of glass)

-Weather resistance: Passed 5000 hours QUV accelerated aging test

-Extended reading: Acrylic material performance comparison table – Acrylic Fabrication Council

2. How to scientifically choose the thickness of acrylic signs?

Follow the “3mm-5mm-8mm” rule:

-Indoor signs: 3mm (single-point suspension load ≤ 2kg)

-Commercial space: 5mm (M6 bolts are recommended)

-Outdoor signs: ≥8mm (windproof brackets are required)

3. How long is the outdoor service life of acrylic signs?

According to the accelerated aging test:

-General environment: 5-8 years (UV intensity ≤ 0.5W/m²)

-High humidity and high heat area: 3-5 years (UV protection coating needs to be applied every year)

-Certification standard: ASTM G154 cyclic test protocol

Conclusion: Systematic Engineering for Building Brand Space

Acrylic sign hanging is not a simple physical fixation, but a systematic engineering that integrates material science, ergonomics and brand strategy. From molecular-level material selection to centimeter-level spatial positioning, each link directly affects the conversion efficiency of commercial value. It is recommended that enterprises refer to the ISO 9001 quality management system to establish a standard hanging process, and consult professional certification agencies such as UL Solutions when necessary. When technical precision and artistic aesthetics are perfectly unified, acrylic signs will become the most cost-effective space investment for brands. Contact Sanyu Acrylic for more information.