-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Acrylic Sheet Solutions: Casting vs Extrusion Techniques

Highly transparent, high-strength, and highly plastic organic glass is quietly changing the material landscape in the fields of architecture, medical treatment, and consumer electronics.

Acrylic (PMMA), scientifically known as polymethyl methacrylate, is a high-performance transparent polymer with a history of nearly 100 years. With a light transmittance of up to 92%, which exceeds that of ordinary glass, and weighs only half of the latter, this material perfectly interprets the essence of the definition of “organic glass” – lightness and toughness coexist, a modern material solution for the symbiosis of safety and beauty.

In the field of building lighting, the roof structure made of acrylic extruded boards has high strength and light weight, and is widely used in high-end construction projects around the world; in the medical field, its non-toxic properties meet the strict hygiene standards of baby care boxes and surgical instruments; in electronic products, the hardness of the mobile phone screen protective layer made of ultra-transparent PMMA can reach more than 5-6H, becoming the “invisible armor” of high-end equipment.

The acrylic sheet market is expanding steadily at an average annual compound growth rate of 5.25%, and the global market size is expected to exceed US$4.91 billion in 2029. The Asia-Pacific region, especially China, has become the main engine driving this growth.

Injection molding: the precision art of acrylic manufacturing

Acrylic injection molding technology is a delicate control of temperature and time. Since PMMA has a water absorption of 0.5%-0.6%, pretreatment needs to be dried at 80-90℃ for 2-3 hours to eliminate melt ripples and bubbles caused by moisture. The temperature window in the melting stage is narrow, and the melting temperature is controlled at 240-270℃. If you are not careful, it will cause thermal decomposition-the retention time at 270℃ shall not exceed 8 minutes, and the safety period at 250℃ can only be maintained for 10 minutes.

The melt fluidity is significantly lower than that of PS or ABS, and it is necessary to balance the filling speed and internal stress through multi-stage injection technology. The mold temperature is set at 35-70℃, combined with a medium injection speed to avoid silver streaks or late cracking caused by residual stress in the product.

This precision control enables acrylic to be formed into complex thin-walled parts, from light guides to medical blood storage containers, showing high dimensional stability.

Physical properties: Transparent miracle beyond glass

The core advantage of acrylic lies in its excellent combination of optical and mechanical properties. The light transmittance is over 92%, surpassing ordinary glass, and the ultraviolet transmittance is as high as 73%, making it an ideal material for greenhouse ceilings and ultraviolet disinfection equipment.

Its impact resistance is even more amazing – The strength is 7-18 times that of ordinary glass, and a 0.5cm thick plate can withstand pistol shooting, and only blunt-edged fragments are produced when broken. Therefore, European and American countries have legislated to force primary and secondary schools to use acrylic instead of traditional glass.

- Outstanding lightweight advantages: density is only 1.19g/cm³, 50% lighter than glass, greatly reducing the load of building supports

- Strong environmental tolerance: Excellent weather resistance, not easy to yellow and hydrolyze under sunlight, and service life is more than 3 years longer than ordinary materials

- Safe and environmentally friendly characteristics: No toxic gas is released during combustion, and the only products of complete combustion are CO₂ and water, which meet the medical food grade contact standards

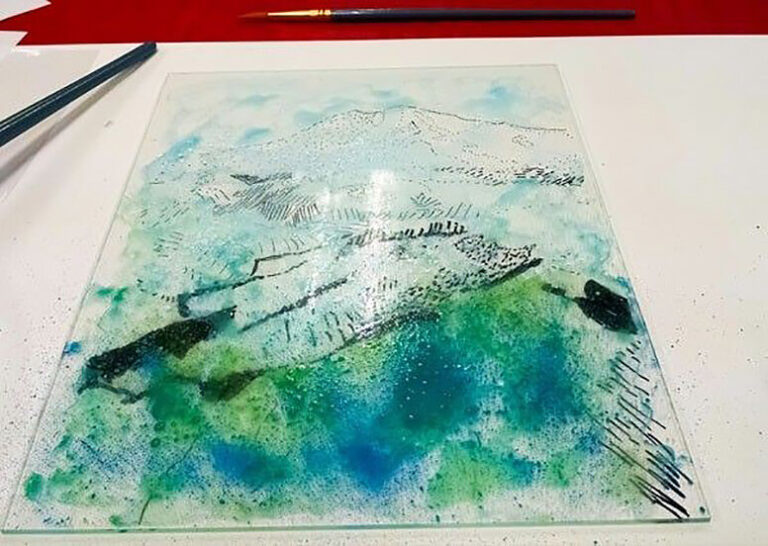

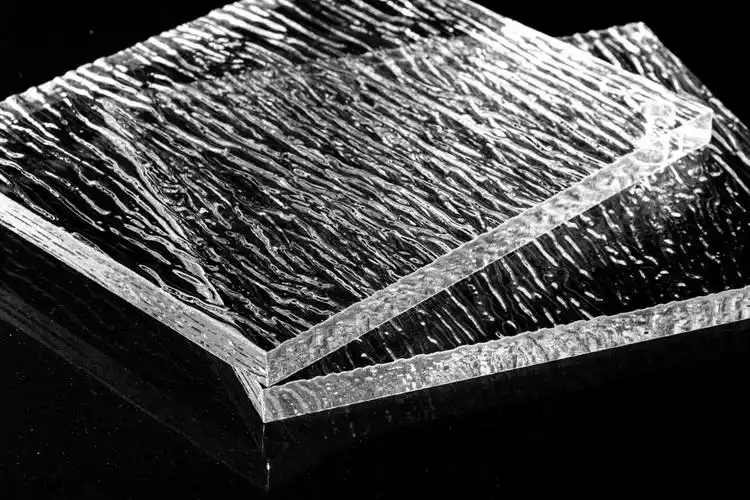

Production process: The evolution of casting and extrusion

The production process of acrylic sheets is divided into two major technical routes: casting molding and extrusion molding, each with its own advantages.

Casting process uses a new MMA monomer as raw material, which is poured into the template under the action of an initiator and polymerized in a water bath oven. The resulting sheet has a high molecular weight, top surface hardness and chemical resistance, and the thickness tolerance is controlled within ±0.3mm. It is especially suitable for small-batch color board production and is irreplaceable in the field of decorative panels and high-end signage.

Extrusion process uses pre-polymerized PMMA particles and continuously calenders them through an extruder. Its advantage lies in ultra-thin plate production capacity – the thickness can be as low as 0.3mm, and the thickness tolerance is more precise (±0.2mm). However, the molecular weight is low, and the mechanical properties are slightly inferior to cast plates. It is suitable for large-scale standardized products such as advertising light boxes and food display covers.

Technological innovation has never stopped, such as laser cutting accuracy of 0.1mm, high-pressure water jet cutting can form complex curved surfaces, and CNC engraving can achieve micro-hole arrays, promoting continuous breakthroughs in design freedom.

Application territory: from architectural landmarks to operating tables

Acrylic’s application map has covered nine core areas:

- Architectural structure: skylights, storm-proof windows, safety stair handrails, the curved curtain wall of the Shanghai Tower confirms its engineering reliability

- Advertising display: The light box has a light transmittance of over 90%, and with the silk-screen printing technology, it achieves the light and shadow aesthetics of urban commerce

- Transportation equipment: subway windows, aircraft cabin covers, double protection against UV and impact

- Medical health: Infant incubators, surgical instrument trays, biocompatibility certification

- Consumer electronics: mobile phone light guide plates, TV diffusion films, hardened coatings with a hardness of 5-6H and scratch-resistant screens

- Home revolution: moisture-proof bathroom partitions, shapeable chandeliers, the share of acrylic furniture at Milan Design Week surged by 35%

- Optical technology: DVD substrates, optical fiber catheters, refractive index 1.49 near-perfect optical media

- Green Energy: Solar collector cover, 73% UV conversion boosts photothermal efficiency

- Food contact: Beverage display cabinets, sterile operation hoods, FDA-certified safety materials

Market Prospects: Asia-Pacific leads the 100 billion track

The acrylic sheet market is expanding at a 5.25% compound annual growth rate, and the scale is expected to reach US$4.91 billion in 2029. The Asia-Pacific region accounts for 43% of global production capacity, and China, India, and Vietnam have become a growth triangle, driven by the dual engines of increasing urbanization and expanding retail industry.

International giants such as Mitsubishi Chemical and Arkema are accelerating the layout of high value-added product lines, such as:

- Antistatic board: electronic workshop partitions

- Anti-glare board: highway signs

- Composite flame-retardant board: high-speed rail interior materials

- Light guide plate: ultra-thin advertising light boxes

The intelligent production revolution is underway – Germany’s Evonik Industries introduced a centralized control system to achieve unmanned casting lines, and the robot assembly accuracy in the injection molding workshop reached 0.05mm, indicating that “dark factories” will become the industry standard.

Sustainability: The future of green materials

Acrylic’s environmental protection gene is being deeply activated. Its recyclability rate exceeds 90%, and waste panels can be restored to MMA monomers for recycling after cracking, and its carbon footprint is 52% lower than that of glass.

On the process side, water-based coatings replace solvent-based paints, reducing VOC emissions by 70%; the waste heat recovery system in the manufacturing process reduces energy consumption by 30%, making acrylic a recommended material for LEED-certified buildings.

Bio-based PMMA has made a breakthrough. Japan’s Mitsubishi Chemical has successfully extracted MMA monomers from bagasse, and commercial products will be launched in the high-end market in 2024.

Process Challenges: Defect Control and Innovative Solutions

The technical pain points in acrylic processing are being systematically resolved:

- Bubble Defect: Vacuum bubbles are solved by optimizing the mold flow channel, and volatile bubbles are eliminated by pre-drying the raw materials

- Welding Mark: Raising the melt temperature to 265℃, combined with a multi-venting groove design, the joint strength is increased by 90%

- Warping Deformation: Residual stress is released through the annealing process, and heat treatment at 80℃ for 2 hours restores molecular balance

New processes such as micro-foaming injection molding technology, injecting supercritical nitrogen during the injection molding stage, reducing material usage by 15% while improving bending strength; nano-imprinting surface treatment, realizing anti-fingerprint, self-cleaning multi-functional integration.

Future Trend: Integration of Intelligence and Function

The next decade of the acrylic industry will be reshaped by three major innovation directions:

- Intelligent Response Materials: Photochromic acrylic window glass has been verified in the laboratory, and it automatically fogs when the ultraviolet intensity exceeds the threshold

- Conductive Composite Panel: Transparent electrode panels doped with graphene will be integrated into the vehicle display system

- Structural Function Integration: Load-bearing and lighting composite panels have attracted attention at the Milan Architecture Exhibition, and the boundaries between walls and windows have melted

In the field of building integrated photovoltaics (BIPV), the conversion efficiency of transparent solar acrylic panels has exceeded 8.7%, and the transformation of skyscraper curtain walls into generators has gone from concept to practice.

Looking at the evolution of acrylic, from the bulletproof hatch of fighter jets to the light-guiding screen of smartphones, from the baby incubator in the operating room to the transparent battery of photovoltaic buildings, this material born in 1931 is reshaping the boundaries of the industry with unprecedented vitality.

When Mitsubishi Chemical’s bio-based PMMA begins to replace petroleum raw materials, and when smart dimming acrylic windows enter green buildings, we are witnessing not only an upgrade of a material, but also a material revolution for a sustainable future. The story of acrylic proves that the most transparent material often contains the most complex possibilities.