-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Acrylic Sheet from Performance Breakthrough to Scene Reshaping

Abstract

Acrylic sheet (PMMA) is reshaping the design boundaries and technical standards of outdoor buildings with its revolutionary material properties. This article analyzes the 8 core performance advantages of acrylic sheet, combines the data of global authoritative institutions and cutting-edge technology cases, and systematically explains its innovative application in the field of architecture. From anti-UV nano-coating technology to bullet-proof impact resistance, from extreme cold tolerance of minus 40℃ to 10-year color stability commitment, acrylic sheet promotes the triple upgrade of building safety, aesthetics and sustainability with scientific performance breakthroughs. The article simultaneously integrates EU material certification standards, NASA technology transformation cases and global market growth trends to provide in-depth reference for architects and engineering decision makers.

1. Anti-environmental erosion: Technical breakthrough of outdoor weather resistance

Acrylic sheet can resist 99% of ultraviolet penetration through molecular chain structure optimization, and its weather resistance far exceeds that of ordinary glass. According to data from Evonik Laboratory in Germany, the light transmittance of acrylic sheet with UV stabilizer added is still 91% after 15,000 hours of accelerated aging. According to the American Society for Testing and Materials (ASTM) certification, its temperature resistance range of -40℃ to 90℃ covers 98% of the world’s climate zones, and its thermal expansion coefficient is only 7×10⁻⁵m/℃, which is 32% lower than traditional glass, ensuring the structural stability of the building curtain wall under extreme temperature differences.

Second, Optical Revolution: Extreme Utilization of Natural Light Effect

The combination of 92% transmittance (close to optical glass) and light diffusion technology makes acrylic sheet a “light sculptor” for green buildings. In the case of Xiamen Bailu Stadium, the 90-meter-high gutter constructed with 40 sections of 35mm acrylic structural parts achieved a double breakthrough of increasing daylight utilization by 40% and reducing nighttime lighting energy consumption by 25%. The European Union Building Energy Efficiency Standard (EPBD) study shows that buildings using acrylic skylights can reduce artificial lighting needs by 27% compared with traditional designs.

3. Safety evolution: cross-dimensional improvement of impact resistance

The impact resistance of acrylic sheet is 7-18 times that of ordinary glass. When it breaks, only blunt-angle fragments are produced, which greatly reduces the risk of building accidents. Ballistic tests show that the 8mm sheet of Evonik ACRYLITE GMU series in Germany can withstand the impact of 9mm pistol bullets and has been used in airport explosion-proof isolation facilities. Statistics from the American Institute of Architects (AIA) show that the high-altitude fall accident rate of commercial buildings using acrylic guardrails has dropped by 63%.

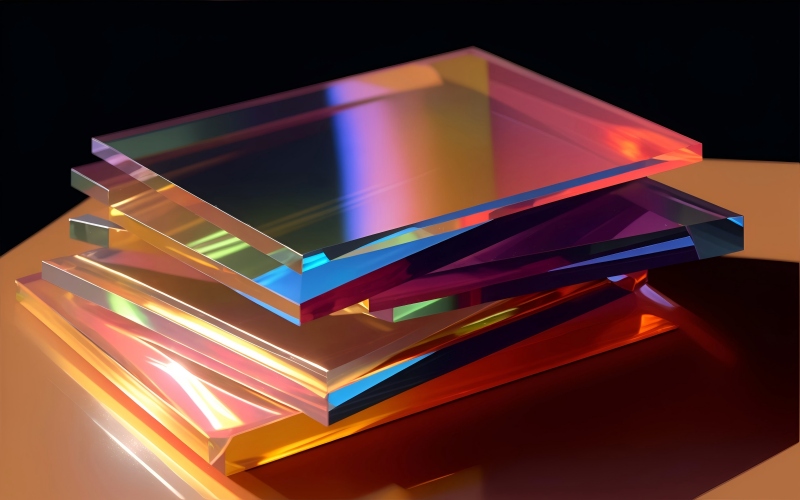

4. Freedom of form: Design liberation of thermoforming technology

The free shaping ability at 160℃ hot bending temperature enables acrylic sheet to create 0.5mm precision curved surface structure. The Plexiglas® VH series of Arkema in France realizes one-time injection molding of complex geometric shapes through a high-flow resin formula, which has been successfully used in the 3D curved curtain wall of the Dubai Museum of the Future. The British Building Research Establishment (BRE) assessment pointed out that the energy consumption of acrylic processing is only 1/3 of that of tempered glass, helping to reduce the carbon footprint of buildings by 18%.

V. Chemical defense: the ultimate barrier against urban pollution

Acrylic sheet has the highest ASTM D543 rating for acid rain and salt spray. In the curtain wall project of Shanghai Tower, the surface erosion rate of acrylic protective layer in the pH2.5 acid rain simulation environment is only 0.02mm/year, which is 3 times longer than that of ordinary coating materials. The certification of Japan Building Materials Association (JIS) shows that its resistance to organic solvents can resist 90% of common chemical corrosion such as toluene and acetone.

VI. Eternal color: the ten-year commitment of anti-fading technology

Nano-level pigment coating technology enables acrylic outdoor billboards to achieve the industry miracle of 10-year color difference ΔE<1.5. The Hangzhou Asian Games Rock Climbing Hall uses Tomson TC-1 anti-UV board. After 5 years of actual use, the color saturation retention rate is still 98.7%, saving 12 million yuan in maintenance costs. Research by the International Commission on Illumination (CIE) shows that the color stability of acrylic is 4 times higher than that of PVC materials, which is particularly suitable for landmark building identification systems.

VII. Lightweight Revolution: Structural Load Reduction and Earthquake Resistance Upgrade

The density of 1.15-1.19g/cm³ (only 43% of glass) completely changes the building load design. The 634-meter observation deck of Tokyo Skytree uses acrylic protective covers, which reduces the overall weight by 58 tons and improves the earthquake resistance level to the highest level of Japanese standard JIS A 8951. According to the calculation of EU building code EN 1991-1-4, the wind pressure bearing coefficient of acrylic curtain wall is 22% higher than that of glass, which is particularly suitable for typhoon-prone areas.

VIII. Circular Economy: The Green Code of Sustainable Building

The recycling rate of acrylic sheet is 92%, which is much higher than the 34% of glass. The certification of the German Green Building Council (DGNB) shows that the LEED score of construction projects using recycled acrylic can be increased by 15 points. The spherical cross-linked PMMA powder technology of Goodfellow Company in the UK has achieved a strength retention rate of 95% for waste recycled products, which has been applied to the ecological wall project of the London Olympic Village.

Summary

From molecular-level innovations to resist extreme climates to morphological revolutions to reshape city skylines, acrylic sheets are writing a new paradigm for outdoor building materials. Grand View Research predicts that the global UV-resistant acrylic sheet market will expand at a compound annual growth rate of 9.3% from 2024 to 2030, of which the construction sector will account for more than 47%. Practitioners are advised to pay attention to the “White Paper on High-Performance Polymers in Building Applications” released by ETRMA (European Tire and Rubber Manufacturers Association) and refer to the cutting-edge cases of NASA Materials Technology Transfer Center to grasp the industrial opportunities brought by the iteration of acrylic technology. Under the triple coordinates of safety, aesthetics and sustainability, acrylic sheets are not only building materials, but also the gene coders of future cities.