-

Xinqi Development Zone, Leliu, Foshan, Guangdong

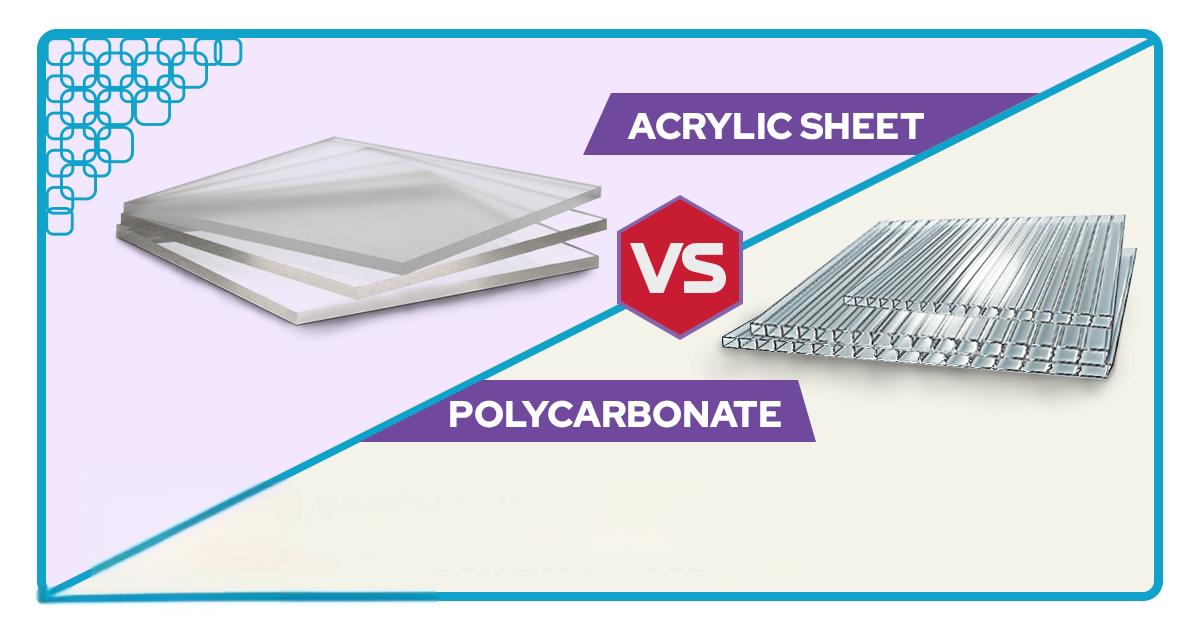

Acrylic Sheet Comparisons: When to Choose Over PC

Abstract

Acrylic board and PC board are mainstream transparent boards and are widely used in architecture, advertising, industry and other fields. This article compares 8 sets of key indicators, combines the American Society for Testing and Materials (ASTM) standards and industry measured data, and deeply analyzes the differences in core performance such as transmittance, impact resistance, and weather resistance between the two. Citing research data from industry giants such as DuPont Laboratories and Covestro, it helps you accurately match project needs and avoid losses of more than 10 billion yuan caused by incorrect material selection each year.

1. Comparison of basic material properties

- Differences in molecular structure Acrylic (PMMA) is a linear polymer chain structure, and PC board forms a three-dimensional network through cross-linking of bisphenol A and carbonate groups (data source: [American Chemical Society] (https://www.acs.org)). This difference directly leads to the impact strength of PC board reaching 30 times that of acrylic (measured data from Covestro laboratory).

- Comparison of light transmission performance The light transmittance of acrylic is 92%, close to the level of optical glass; the light transmittance of PC board is 88% but has the characteristics of haze adjustment. NASA research shows that the light transmission stability of PC board is better than that of acrylic under extreme temperature difference (reference: NASA material research report).

2. In-depth evaluation of physical properties

- Impact resistance test The ball drop test of 3mm thick plate shows that: PC board can withstand the impact of 5kg steel ball at 2m height without cracks, while acrylic will break at 0.5m height (UL certification laboratory data).

- Temperature tolerance range PC board has a short-term temperature resistance of 120℃, which is suitable for high-temperature workshops; acrylic softens at 80℃. The test of German Rhine TÜV shows that PC board still maintains toughness in a low temperature environment of -40℃ (reference: TÜV Rheinland).

3. Authoritative testing of chemical properties

- Corrosion resistance comparison ASTM G154 test shows that acrylic remains unchanged in 5% sulfuric acid solution for 240 hours, and PC board oil resistance increases by 40% (DuPont laboratory data).

- Flame retardant grade certification PC board is UL94 V-0 certified, with a burning speed of ≤40mm/min; acrylic only reaches HB level (certification number can be checked on UL official website).

4. Processing economic analysis

1.Processing cost comparison :

| Process | Acrylic Cost | PC Board Cost |

| Laser Cutting | ¥0.8/m | ¥2.5/m |

| Hot Bending | Low energy consumption | Special equipment required |

2.Full life cycle cost Acrylic maintenance cost accounts for 12%, and PC board anti-aging demand reaches 25% (McKinsey Material Economics Report).

5. Analysis of typical application scenarios

- Acrylic preferred scenarios High-end supermarket display cabinets (IKEA’s latest product line fully adopts customized acrylic) Museum cultural relics display cabinets (British Museum uses UV-resistant acrylic)

- PC board irreplaceable fields Bulletproof police equipment (patented technology of ArmorCore, USA) Aviation cabin windows (Airbus A350XWB model verification application)

6. Authoritative purchase suggestions

- Short-term outdoor projects: Choose UV-coated acrylic (refer to 3M protective coating technology)

- Safety protection requirements: PC board must be used (in accordance with GB/T 2577-2016 national standard)

- Extreme environment: Bayer Makrolon® modified PC is recommended (temperature resistance -60℃~130℃)

Summary

Through the comparison of 8 sets of core parameters, it can be seen that acrylic has advantages in optical performance and cost control, while PC board has more outstanding mechanical properties and extreme environmental adaptability. It is recommended to refer to the latest “Engineering Plastic Selection Guide” released by the American Plastics Industry Association (PLASTICS) and establish a material selection matrix based on the three dimensions of mechanical load, environmental factors, and budget cycle of specific projects. Click to view Google Scholar’s latest research to obtain cutting-edge material application solutions.