-

Xinqi Development Zone, Leliu, Foshan, Guangdong

Acrylic Luminous Technology: Lighting Up The City

A soft and uniform light shines from the inside of the transparent plate, decorating the city night as a gallery of light.

As night falls, the city does not fall asleep. Those luminous signs standing quietly on the tops of skyscrapers, at the entrances of commercial blocks and on the walls of shopping malls turn the night into another day. Most of these soft and eye-catching light sources come from a revolutionary technology – acrylic luminous technology.

As the core carrier of modern advertising logos and urban aesthetics, acrylic luminous technology uses high-energy lasers to accurately engrave inside acrylic to form complex patterns or texts, and combines with LED light sources to make the engraved parts emit uniform and soft light**.

This visual miracle not only changes the night view of the city, but also redefines the artistic expression of commercial communication and public space.

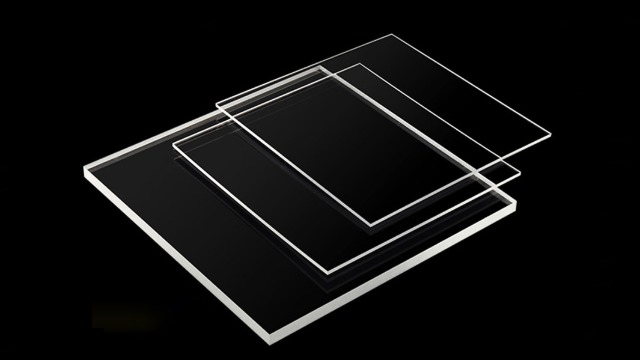

Material Revolution: The Technological Core of Transparent Substrates

Acrylic, scientifically known as polymethyl methacrylate (PMMA), as an important member of the organic glass family, is by no means an ordinary plastic. Its technological core lies in unique physical and optical properties: light transmittance is as high as 92%, exceeding that of ordinary glass; it also has excellent weather resistance, impact resistance and processing plasticity.

This material revolution began in the laboratory in the early 20th century, but became the shaper of urban landscape a hundred years later.

Compared with traditional luminous materials, acrylic shows overwhelming advantages. When ordinary glass faces the risk of fragility and when metal plates encounter light restrictions, acrylic plates greatly reduce the difficulty of installation and the cost of supporting structures by virtue of 50% weight reduction.

More importantly, its light control ability – through a special surface treatment process, light is diffusely reflected in the acrylic plate, forming a uniform luminous effect, avoiding the problem of dazzling light spots.

Table: Performance comparison between acrylic and traditional luminous materials

| Characteristics | Acrylic | Traditional glass | Metal plate |

|---|---|---|---|

| Light transmittance | More than 92% | 85%-90% | Opaque |

| Impact resistance | High (10 times that of glass) | Low | High |

| Weight | Light (density 1.18g/cm³) | Heavy | Medium |

| Processing performance | Easy to cut and engrave | Difficult to process | Medium |

| Light uniformity | Excellent | Medium | Poor |

Material purity determines the height of the process. Acrylic sheets in the market are divided into three categories: imported, domestic and Taiwanese. The essential difference lies in the origin of raw materials and the purity of MMA monomer. The hardness index of high-quality plates is outstanding, which eliminates the phenomenon of shrinkage, bending and deformation. There will be no cracks on the surface during processing, which lays a molecular foundation for the visual performance of high light transmittance.

Laser internal engraving: the precise dance of light and material

The core breakthrough of acrylic luminous technology comes from the revolutionary application of laser internal engraving technology. This technology uses high-precision laser to perform micron-level dot inside acrylic to form a predetermined pattern or text structure.

The engraving depth, dot density and distribution pattern are precisely calculated. When the internal light source is lit, these microscopic structures become light guiding media, making the entire engraving area emit a uniform moonlight-like light.

Laser internal engraving achieves a level of precision that traditional processes cannot achieve. In the field of advertising logos, the aesthetic expression of Chinese character strokes was once a technical bottleneck-strokes as thin as 4mm or less can still maintain a complete luminous structure, and strokes as thick as 5mm or more can also achieve uniform light distribution.

This microscopic control capability enables the smooth and flowing strokes of Chinese calligraphy to be perfectly reproduced on the photoelectric carrier, giving the ancient art of Chinese characters a new lease of life in modern cities.

The advantages of laser engraving are not only reflected in precision, but also bring about a double breakthrough in environmental protection and durability. The processing process produces almost no waste gas and waste, which meets the green manufacturing standards; the engraved pattern is hidden deep inside the material, and the surface integrity is preserved, avoiding the edge degradation problem caused by traditional etching or cutting.

When an acrylic luminous sign is installed outdoors, it can withstand more than ten years of sun and rain without yellowing and cracking. The technological code behind it is the magical combination of laser and material.

Process Decryption: The Journey from Plate to Luminous Artwork

The production of acrylic luminous characters is an exquisite art that combines traditional craftsmanship with modern technology. According to the detailed description of patent CN111968544A, this process includes seven precise steps:

Material preparation and molding are the basic stages. Scientifically select materials according to the thickness of the font strokes: acrylic plates below 4mm are selected for fine strokes to ensure fineness, and 5mm plates are used for thick strokes to improve structural strength. The side strips are then integrated into a three-dimensional character shell through a special bending machine. This step determines the three-dimensional accuracy of the product.

Optical system construction is the core of the luminous effect. The LED modules with double-sided tape are evenly arranged on the bottom plate, and the circuit design of no more than 40 modules per string ensures the stability of the system. At this time, a 12V low-voltage power supply test is required to ensure that all light sources are working properly.

Sealing process is related to the product life. Applying building waterproof sealant on both sides of the module, this key technology prevents the glue layer from falling off due to sun exposure; the drip hole drilled at the lowest point of each stroke solves the internal corrosion risk of rainwater retention.

The production process of back-lit characters is more sophisticated. Laser cutting ensures that the interface is smooth and burr-free, which is especially suitable for small fonts; the metal frame needs to open a 0.6mm notch to achieve seamless corners; during laser welding, the red heart is accurately aligned with the interface, and the movement error is controlled at the millimeter level. This kind of process precision makes acrylic backlit characters the preferred logo for high-end commercial spaces.

Application scenario: Reshaper of urban visual ecology

Acrylic luminous technology has been deeply integrated into the multi-dimensional space of modern cities, showing its unique charm in different application scenarios.

In the field of commercial advertising, acrylic luminous signs have become the strategic medium for brand communication. In the door heads of shopping malls, brand flagship store signs, and internal guide systems of shopping malls, acrylic characters stand out in the visual competition with high brightness and uniform luminous characteristics.

Its energy-saving characteristics are also amazing-saving more than 60% energy consumption compared to traditional power sources, so that large-scale commercial lighting no longer means huge electricity bills.

The field of cultural display has witnessed the artistic sublimation of acrylic luminous technology. The museum uses acrylic inner carving technology to create an exclusive light environment for precious cultural relics. Through precise light control and color temperature adjustment, bronze ware presents a sense of historical heaviness under 3600K warm light, and silk cultural relics show weaving details in 4000K neutral light.

This UV-free lighting protection makes light and cultural relics reach a perfect reconciliation.

Urban public spaces are rejuvenated by acrylic luminous devices. The guide sign system of the subway station adopts full-body luminous acrylic technology to ensure that the minimum 2 hours of afterglow lighting is maintained in emergency situations such as power outages; the acrylic sculptures in the park are crystal clear works of art during the day and become dreamlike installations of light and shadow at night.

Table: Application requirements of acrylic luminous technology in different scenarios

| Application scenarios | Core requirements | Technology focus | Light source selection |

|---|---|---|---|

| Outdoor billboards | Weather resistance, farsightedness | Waterproof sealing, large character structure | High-brightness LED |

| Shopping mall signs | Aesthetics, brand sense | Fine carving, color restoration | RGB color-changing LED |

| Museum lighting | Cultural relics protection, atmosphere | UV filtering, light uniformity | Low-heat LED |

| Public transportation guidance | Safety, emergency | Afterglow materials, fire protection | Dual circuit power supply |

| Architectural decoration | Structural integration, creativity | Special-shaped processing, three-dimensional modeling | Hidden light source |

Innovation frontier: the future of materials science

The innovation of acrylic luminous technology has never stopped, and breakthroughs in the field of materials science continue to promote industry upgrades. Optical-grade acrylic achieves a light transmittance of more than 98% through nano-level surface coating technology, almost eliminating light loss, making the luminous logo still clearly visible in haze weather.

The development of environmentally friendly materials uses recycled MMA monomers to reduce carbon footprint by 40% while maintaining optical performance, responding to the urgent need for global sustainable development.

The integration and innovation of LED technology has opened up a new dimension. The miniaturized LED module allows the stroke width to break the 3mm limit and achieve the flying white effect in calligraphy fonts; the combination of RGB three-color chips and intelligent control systems allows a single acrylic word to switch freely between millions of colors, injecting dynamic vitality into the city night scene.

A more cutting-edge exploration is the self-luminous acrylic technology, which, by adding rare earth fluorescent materials, allows the board to absorb natural light during the day and automatically release the stored light energy at night, completely getting rid of the constraints of electricity.

Laser engraving technology itself is also undergoing a revolutionary evolution. The newly developed femtosecond laser engraving system improves the processing accuracy to 0.1 micron level, and can construct nanoscale optical structure inside acrylic to achieve precise control of the direction of light propagation.

This technology transforms acrylic sheets into precision optical components, providing ultra-high reliability solutions for special fields such as medical equipment signs and aircraft cockpit signs.

Future Trends: Intelligent Interaction and Ecological Integration

The future of acrylic luminous technology points to two major innovation dimensions: intelligent interaction and ecological integration.

The injection of Internet of Things technology transforms traditional signs into information terminals. The embedded sensors collect environmental data and dynamically adjust the brightness and color of the light – automatically increase the brightness when the ambient light increases, and switch to amber light with stronger penetration in foggy days; connect to the city big data platform through wireless network, and turn to emergency indication system in emergency.

The combination of acrylic material and solar energy technology creates a self-sustaining luminous system. The transparent photovoltaic film and acrylic sheet are integrated into one, collecting energy and storing it in ultra-thin batteries during the day, and supplying LED light sources at night, realizing a complete energy closed loop.

This off-grid lighting solution is providing key technical support for the construction of public facilities and zero-carbon cities in remote areas.

The digital revolution of manufacturing processes is also accelerating. 3D printing technology is applied to acrylic powder materials to achieve mold-free free molding, allowing designers to create complex structures such as hollow curved surfaces and porous light transmission that cannot be achieved by traditional processes. Digital twin technology optimizes the optical path design in a virtual environment, predicts the aging of materials ten years later, and provides full life cycle protection for each work.

Table: Technical innovation direction of acrylic luminous process

| Innovation field | Core technology | Application value | Development stage |

|---|---|---|---|

| Intelligent interaction | IoT sensor | Environmental adaptation, information interaction | Commercial application stage |

| Energy autonomy | Transparent photovoltaic film | Off-grid lighting, zero-carbon operation | Demonstration project stage |

| Advanced manufacturing | 3D printed acrylic | Complex structure, artistic creation | Laboratory stage |

| Optical control | Nano-scale engraving | Medical aviation special logo | Technology verification stage |

| Environmentally friendly materials | Recycled MMA monomer | Sustainable development | Initial stage of industrialization |

Acrylic sheets go from laboratories to city streets, laser engravers weave light paths in transparent materials, and LED light sources quietly release energy in sealed letter shells. From the dazzling commercial signs in Tokyo’s Ginza to the historical building logos on the Bund in Shanghai; from the soft lighting of the Louvre’s display cabinets to the giant luminous fonts of the Burj Khalifa in Dubai.

Acrylic luminous technology has quietly reshaped the urban visual ecology of the 21st century. According to industry forecasts, with the breakthrough of the integration of intelligent interaction and green energy technology, 30% of urban public lighting will be replaced by self-sustaining acrylic luminous systems in the next five years.

When night falls again, the city’s light and shadow picture will open a new page – this page is written by technology and art.

A ray of light is tamed by the material, and a city is gently lit.