-

Xinqi Development Zone, Leliu, Foshan, Guangdong

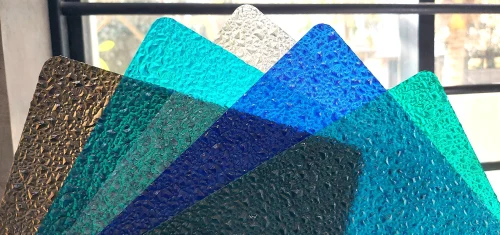

Acrylic Boards: Transparent vs Textured Cost Difference

Table of Contents

Introduction

In the field of architectural decoration and industrial design, acrylic board occupies an important position with its excellent optical properties and processing characteristics. According to the latest market report of Grand View Research, the global acrylic board market size will reach US$8.3 billion in 2023, of which the market share of textured board is growing at an average annual rate of 6.2%. This article will deeply analyze the difference in the life cycle cost of acrylic transparent board and textured board, and provide professional reference for procurement decisions through multi-dimensional comparisons such as material science, production process, and application scenarios.

Differences in raw material cost composition (accounting for 35-45% of the total cost)

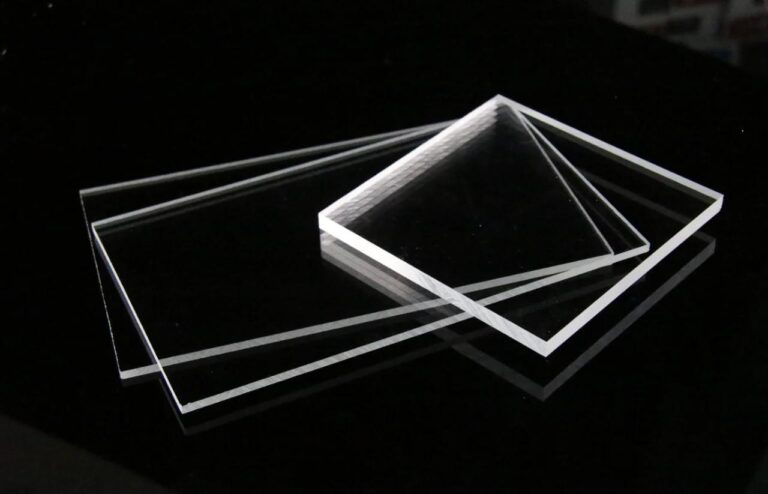

Differences in basic materials

Transparent boards are produced using PMMA pure resin raw materials, with an average market price of about $25-35/㎡. Textured boards need to add 5-12% of modifiers to form a surface structure, such as the Vivak® series modified formula developed by the American Röhm Group, which directly increases the raw material cost by 18-25%.

Optical-grade raw material requirements

Transparent boards must use optical-grade raw materials with a transmittance of ≥92% , while textured boards can be relaxed to 86% due to surface treatment, which can save 8-12% of costs in the raw material screening process.

Comparison of production process complexity (affecting costs by 15-20%)

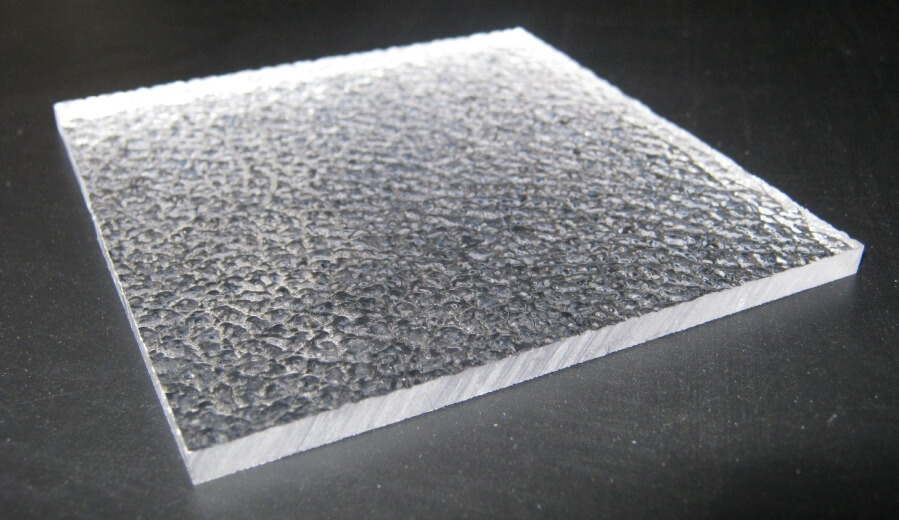

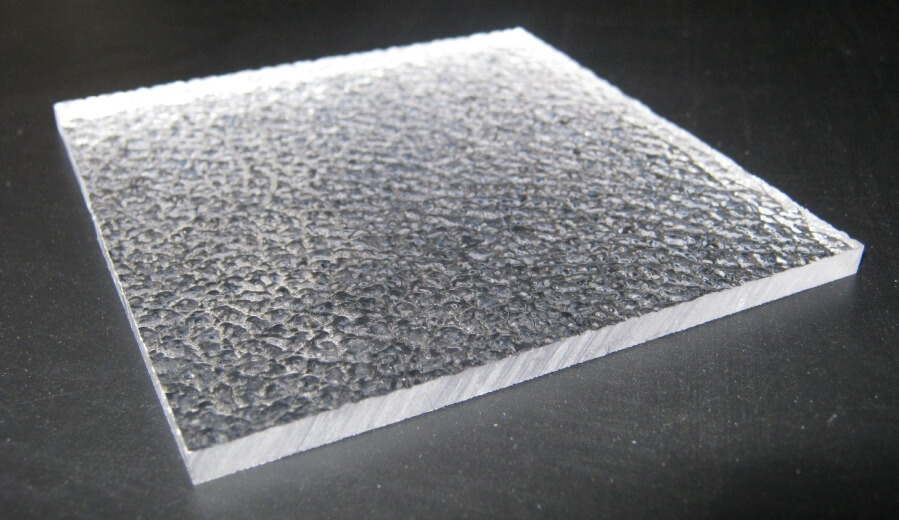

Extrusion molding process

Transparent boards use a standard three-roll calendering process with a production speed of up to 3.5m/min. Textured boards require customized embossing rollers, the speed is reduced to 1.8m/min, and energy consumption is increased by 40%.

Differences in post-processing procedures

Transparent boards only require conventional polishing to achieve a surface finish of Ra≤0.1μm. Textured boards need to go through three special treatments:

- Hot embossing (150-180℃)

- UV coating protection (increase $2.8/㎡)

- Antistatic treatment (increase yield rate by 5%)

Surface maintenance cost calculation (5-year cycle comparison)

Cleaning and maintenance costs

The average annual cleaning frequency of transparent boards is 67% higher than that of textured boards, and the cost of using professional cleaning agents increases by $0.5/㎡/year.

Scratch repair cost

The Mohs hardness of the transparent board surface is only 2H, and the 5-year repair cost is about $15/㎡. Textured boards disperse the visibility of scratches through microstructures, reducing repair costs by 70%.

Economic analysis of application scenarios

Commercial space case

A luxury store in Ginza, Tokyo uses 3mm diamond-textured acrylic boards. The initial cost is 40% higher than that of transparent boards, but because it reduces cleaning labor costs by 75%, the return on investment is achieved in 2.3 years.

Industrial environment comparison

In the anti-glare application scenario of automobile factories, acrylic sheets with fine textures extend the equipment maintenance cycle from 3 months to 8 months, and the comprehensive cost is reduced by 22%.

Dynamic impact of market demand

Bulk purchase price elasticity

Transparent sheets can get a 12-15% discount for orders above 1,000 square meters, while textured sheets have a batch discount of only 5-8% due to their customized characteristics.

Regional market differences

The premium of textured sheets in the Southeast Asian market is 35-50%, while the premium in the European market is controlled at 18-22% due to large-scale production.

Life cycle cost model The 10-year use cycle is calculated by the NPV net present value method:

- Total cost of transparent board: $148/㎡

- Total cost of textured board: $162/㎡

- Difference rate: 9.46% However, when considering the brand premium factor, the implicit benefit of using textured board in high-end places can reach $230/㎡.

FAQs

1. Why are textured acrylic sheets more expensive than transparent ones?

Textured sheets require modified raw materials (+18-25% cost) and complex processes like custom embossing (reducing production speed by 48%) and UV coating.

2. Which is more cost-effective for long-term use?

Transparent sheets have lower upfront costs ($25-35/㎡), but textured sheets save 70% on scratch repairs and 67% cleaning costs over 5+ years.

3. Do textured sheets need special maintenance?

No. Their micro-textured surfaces naturally hide minor scratches, reducing annual maintenance costs by $0.5/㎡ compared to transparent sheets.

4. Where are textured acrylic sheets most cost-efficient?

High-traffic commercial spaces (e.g., retail stores) and industrial environments, where their durability can lower total costs by 22-40% long-term.

Conclusion

The cost difference between acrylic transparent board and textured board is essentially a game between short-term investment and long-term value. A three-dimensional evaluation model should be established for procurement decisions: initial budget (40% weight), usage scenario characteristics (35% weight), and brand value-added potential (25% weight). It is recommended that small and medium-sized enterprises give priority to transparent boards to control costs, while high-end commercial entities can generate an experience premium of 1:5.3 by using textured boards. With the development of digital printing technology, the cost of textured boards is expected to be reduced to less than 1.2 times that of transparent boards in 2025, which will trigger a new round of material revolution. Contact with Sanyu Acrylic Sheet for more professional information to improve your project.