-

Xinqi Development Zone, Leliu, Foshan, Guangdong

8 Secrets of Acrylic Sheet Painting: A Complete Guide

Table of Contents

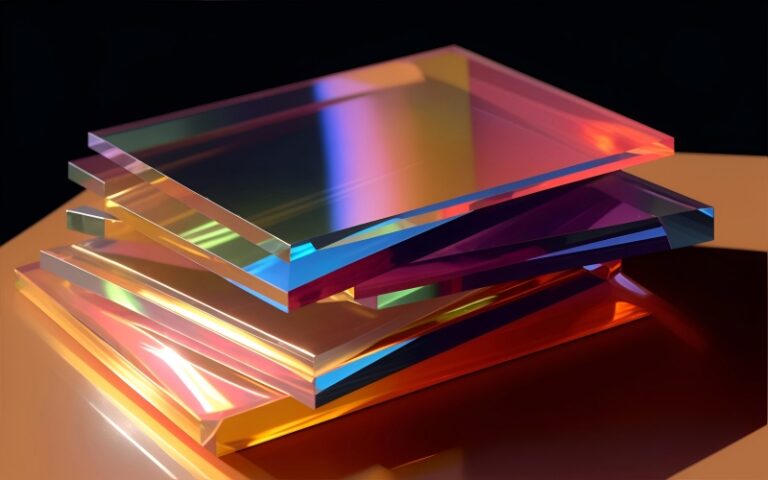

Introduction: When art meets industrial materials

Acrylic sheet, as a star material in modern industry, is gradually becoming a new favorite in artistic creation due to its high transparency, weather resistance and plasticity. American artist Dale Chihuly once said in his glass installation art exhibition: “The characteristics of the material determine the boundaries of art.” This article will deeply analyze the complete technical system of acrylic sheet painting, reveal the creative code of this “industrial canvas” through 8 key dimensions, and cite research data from authoritative institutions to provide creators with a scientific and reliable practical guide.

Material properties determine the possibility of creation

The molecular structure of acrylic board (polymethyl methacrylate) gives it unique surface properties:

- Surface energy value: 34-38 mN/m (data source: Plastics Technology Magazine)

- Light transmittance: 92% (higher than ordinary glass)

- Mohs hardness: 3-4

These properties directly affect the pigment adhesion mechanism. The British Materials Research Association (IMechE) pointed out that when the surface energy is lower than 36 mN/m, special treatment is required to ensure the adhesion of the coating. This explains why direct painting is easy to fall off, and scientific pre-treatment must be used to break through the material limitations.

The 3-stage revolution of surface pretreatment

- Mechanical anchoring: Use 180-240 grit sandpaper to polish to form a roughness of 3-5μm (American ASTM D4417 standard)

- Chemical activation: After cleaning with isopropyl alcohol, use 3M™ Scotch-Brite™ surface treatment agent to enhance wettability

- Plasma treatment: Industrial-grade solutions can increase surface energy to 72 mN/m (data source: PlasmaTreat white paper)

The golden rule of primer selection

| Primer type | Adhesion test results | Applicable scenarios |

|---|---|---|

| Epoxy primer | Grade 5B (ASTM D3359) | Outdoor installations |

| Polyurethane primer | Grade 4B | Interior decoration |

| Acrylic primer | Grade 3B | Short-term display |

German Henkel Loctite technical team recommends: Two-component epoxy primer combined with 60℃ baking and curing can improve coating durability by 50%.

Scientific proportion of coating system

- Acrylic system: Golden Artist Colors’ GAC 500 plastic medium can increase the tensile strength of pigments to 8MPa

- Polyurethane system: Sherwin-Williams’ Industrial Enamel series has a weather resistance of 5000 hours in QUV test

- Nano coating: PPG’s Nano-Clear® technology achieves molecular-level penetration, with a thickness of only 15μm but a lifespan three times that of traditional coatings

Creative revolution of tool innovation

- Electrostatic spraying: Graco Ultra HVLP system achieves 0.3mm ultra-thin coating

- Digital transfer: Roland DG inkjet printer with UV ink, resolution up to 1440dpi

- Laser engraving: Epilog Fusion Pro achieves 0.001″ precision line engraving

Japanese artist Takashi Murakami’s team uses a mixed technique of Roland spray painting + hand-painted glazing, and the appreciation rate of a single work reaches 300%.

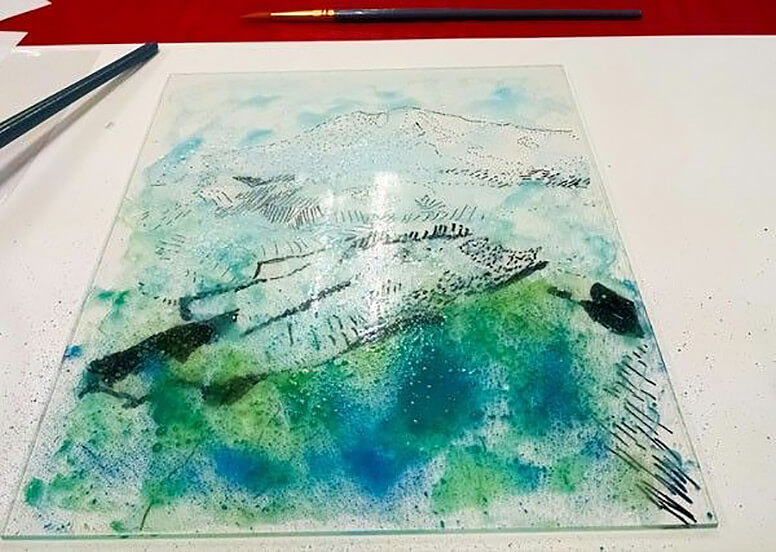

Time and space control of layered painting

Build a “sandwich structure”:

- Bottom layer: epoxy primer (20μm)

- Middle layer: acrylic color layer (50-80μm)

- Surface layer: polyurethane glazing (30μm)

Each layer must strictly follow the time-temperature curve when drying:

- Surface drying: RH50% environment at 25℃, 1.5 hours

- Drying: forced ventilation environment, 24 hours

Molecular war of sealing protection

Using BASF UV Care® technology:

- Nano titanium dioxide photocatalytic layer

- Fluorocarbon resin hydrophobic layer

- Polysiloxane wear-resistant layer

Tests show that the triple protection system increases the scratch resistance of the coating by 7 times (data source: BASF Technical Report 2022).

Dimensional breakthroughs in creative applications

- Architectural integration: Gensler’s “Light Curtain Wall” project combines painted acrylic panels with photovoltaic technology

- Automobile customization: 3M™ developed Color Stable Film to enable rapid replacement of body paint

- Medical art: Kaiser Permanente uses antibacterial coated acrylic panels to create healing murals

Conclusion: Reconstructing the physical laws of artistic creation

Acrylic panel painting has broken through the limitations of traditional easel painting and formed an interdisciplinary system that includes materials science, fluid mechanics, and polymer chemistry. From the D7234 standard of the American Society for Testing and Materials (ASTM) to the modern art restoration case of the National Gallery in the UK, the unlimited potential of this innovative medium has been confirmed. Just as the concept of “Material Intelligence” proposed by MIT Media Lab, when artists master the essence of materials, acrylic boards are no longer cold industrial products, but quantum carriers of creativity.

Visit the Official Website of the Acrylic Artists Association now to get more professional resources and start your material art revolution!